Production line description

Chic Machinery launches a complete set of production line equipment for bottled water filling suitable for water source production, suitable for filling and producing 3-gallon, 5-gallon, or 18.9L capacity barrels, for the filling of purified water, mineral water, mountain spring water, and distilled water. This equipment integrates automatic external brushing bucket, automatic bottle feeding mechanism, automatic bottle washing and disinfection, automatic filling, automatic capping, automatic capping and lamp inspection, heat shrink film, and finished product delivery. The raw materials used meet the requirements of the food industry and other industries. The device adopts AC380V/50HZ AC power supply and Panasonic PLC programmable controller control system. It automatically runs through high-definition touch screen editing program. The power transmission adopts a reduction motor and pneumatic control system, with reliable performance, easy operation, and simple maintenance. The entire process of bottle washing, filling, capping, and sealing is carried out in a closed tunnel, effectively preventing potential secondary pollution of purified water during the filling process, and fully complying with hygiene standards.

According to the production speed per hour, it is divided into small 100 barrels/hour, 200 barrels/hour, 300 barrels/hour, 450 barrels/hour, 600 barrels/hour, 900 barrels/hour, 1200 barrels/hour -2000 barrels/hour.Application

Whole line included

Water treatment system

Raw water tank → quartz sand filter → activated carbon filter → precision filter → reverse osmosis filter → ultraviolet sterilizer→ pure water tank

Raw water tank → quartz sand filter → activated carbon filter → precision filter → reverse osmosis filter → ultraviolet sterilizer→ pure water tank

Allocation system

High-speed emulsification tank →CIP cleaning system

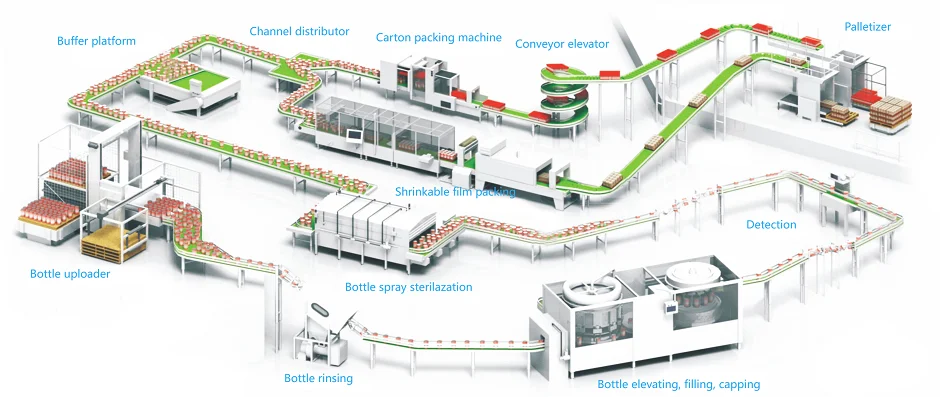

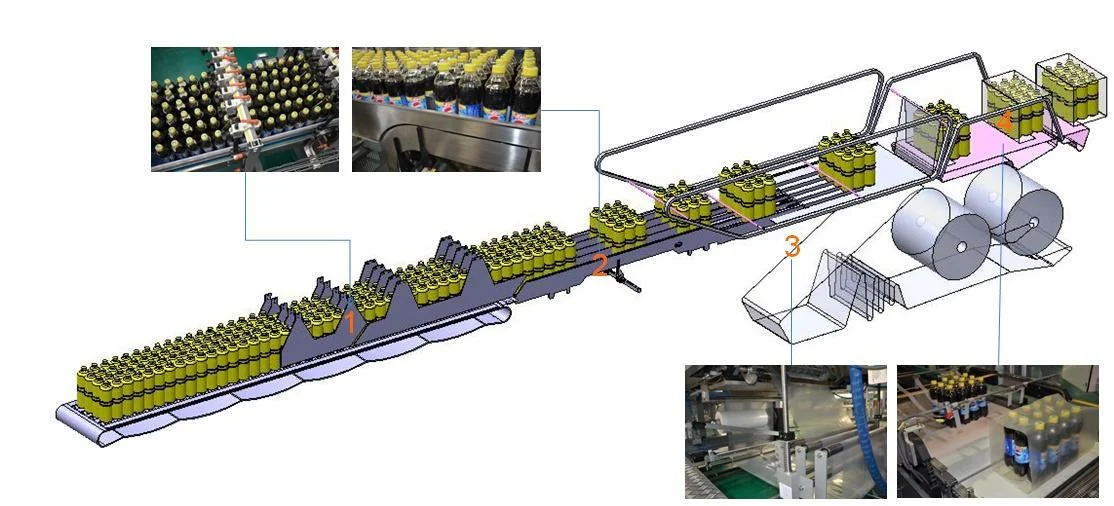

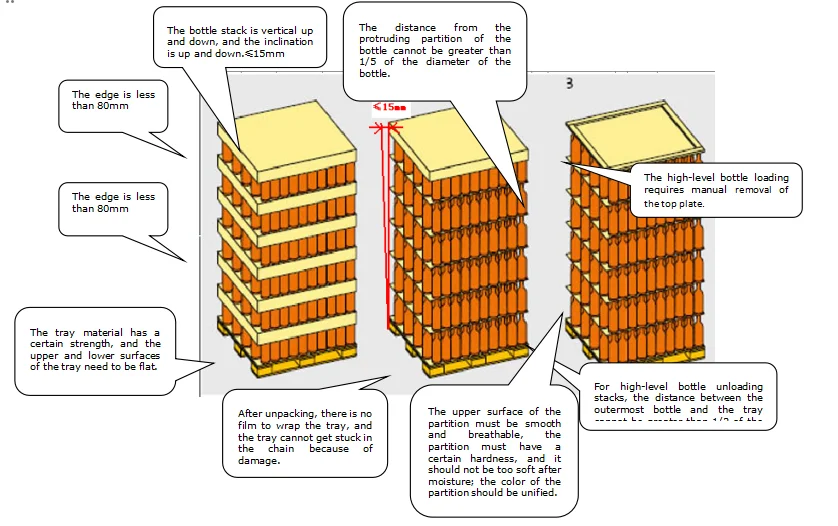

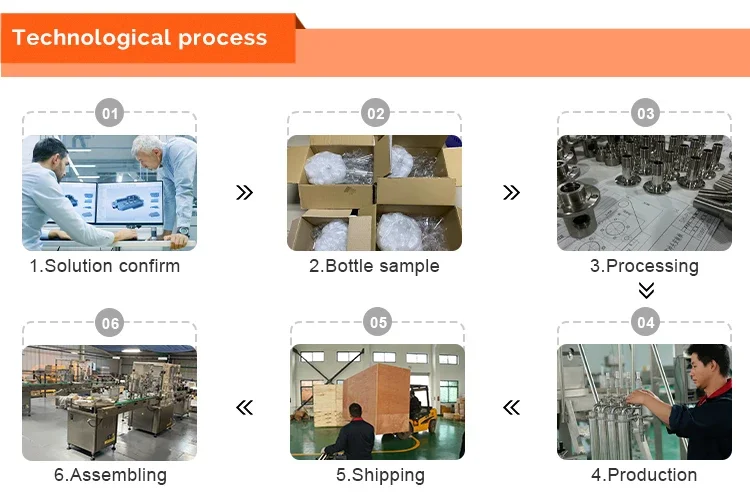

Bottle uploader, bottle washing, fillingand capping 3 in 1 & packaging & palletizing production line

Bottle uploader → three-in-one machine → spray sterilization machine → drying machine → laser coding machine → sleeve label shrinking machine → heat shrinkable film machine → one piece carton packaging machine - Palletizing machine → finished product storage

Bottle uploader → three-in-one machine → spray sterilization machine → drying machine → laser coding machine → sleeve label shrinking machine → heat shrinkable film machine → one piece carton packaging machine - Palletizing machine → finished product storage