[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

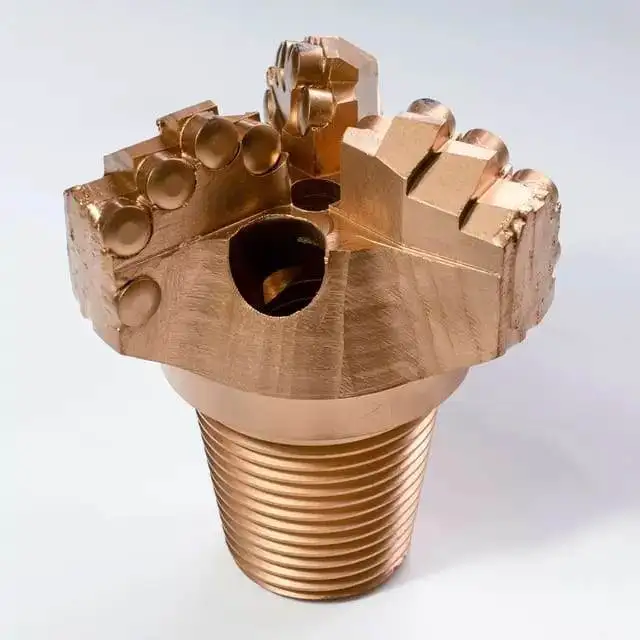

Suku cadang gratis1. Size: | This is 127mm PDC coring drill bit.Available in any size of 50mm-300mm.For example, 75mm, 91mm, 112mm,133mm, etc |

2. Drill bit type: | 10-tooth core drill bit.There are also 4 teeth, 5 teeth, 6 teeth, 8 teeth, 11 teeth, etc |

3. PDC tool size: | 1304,1308,1313,1613,1908 |

4. Valve body material: | PDC cutter+C45#steel |

5. Applicable rocks: | mud rock, limestone, shale, sandstone,granite, etc. |

6. Color: | gray, gold, blue, green,or according to customer requirements |

Type | Adapt to rock formations |

Ordinary PDC drill bit | Soft to medium hard rock with F<10 |

Reinforced PDC drill bit | Medium hard rock with F=10-12 |

High strength PDC drill bit | Hard rock with F<18 |

Cutter size | 13X 8 mm | The smallest cutter suitable for the hardest rock information ,then the biggest cutter gets the fastest speed . | ||||

13X19 mm | ||||||

16X13 mm | ||||||

19X13 mm | ||||||

Diameter (mm) | 28-42 | Material | diamond+hard alloy |

Length (mm) | 32 | Production process | high-quality steel forging and forming |

Weight on bit (Kg) | 300-700 | Main Use | Diamond drill bits are mainly used in industries such as coal fields, oil drilling, geological exploration, water conservancy and hydropower, railways and highways, tunnel construction, etc. across the country |

Speed (rpm) | 300-500 | ||

Pump capacity (1/min) | 150-200 |

Pesanan tiba sebelum jadwal, atau dapatkan kompensasi 10% dari harga pesanan jika pengiriman telat.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan