Suku cadang gratis

Suku cadang gratis

How to choose

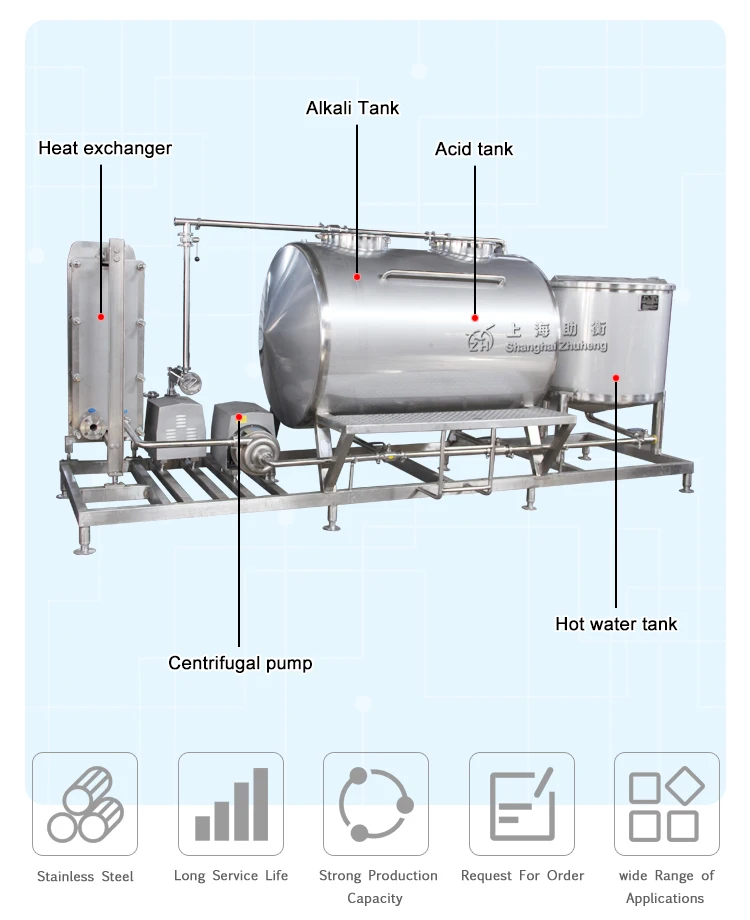

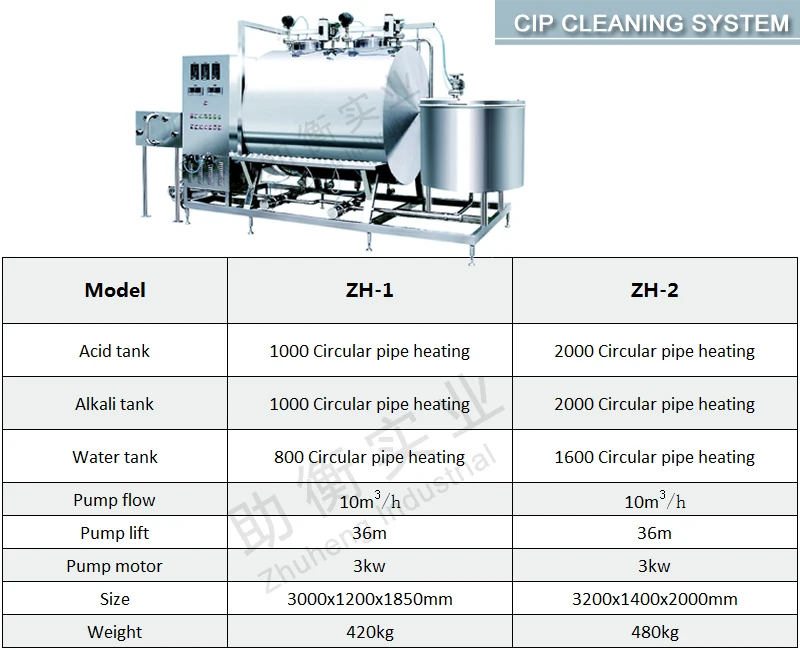

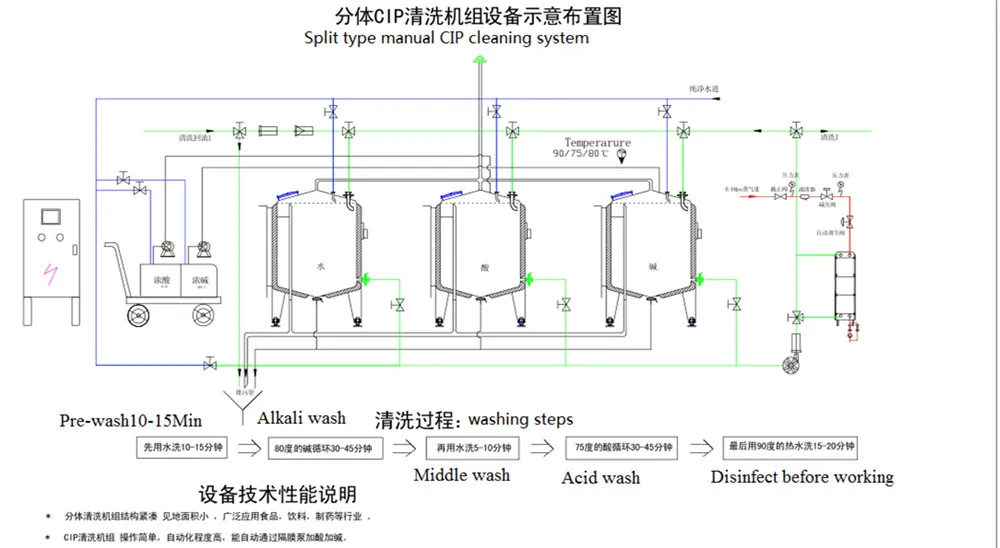

Brand | ZH | Type | Semi-automatic |

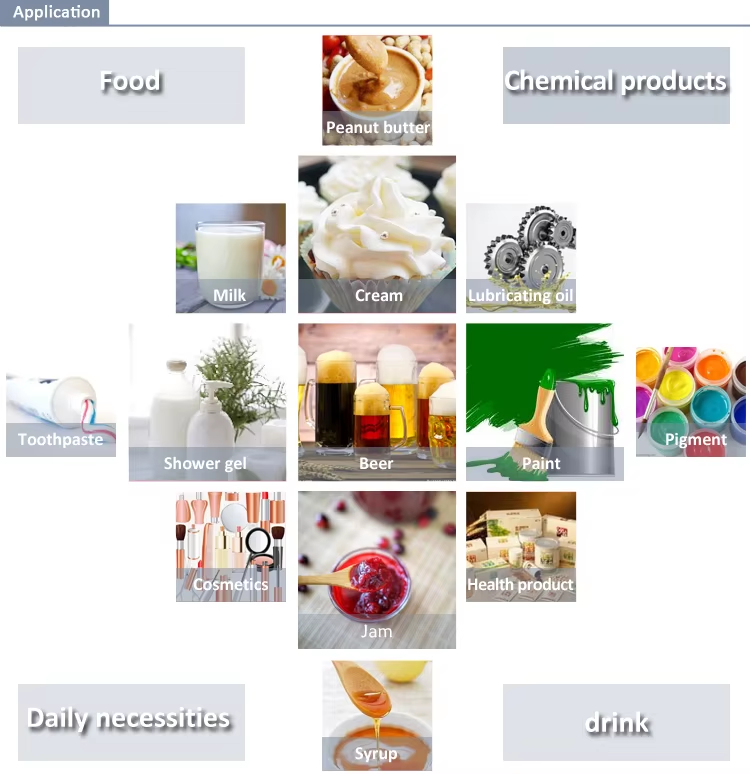

Product name | Siamese Automatic Washing CIP Cleaning System | Processing Types | Beer,Beverage,Milk |

Material | SUS304/316L | Core Components | PLC |

Processing Types | Beverage/diary/medical | Voltage | Local Requirement |

Cleaning type | Liquid Cleaning | Power | 1.5-2.2KW |

Applicable Industrial | Manufacturing Plant, Food & Beverage Factory, Food & Beverage | Capacity | Custom-made |

Type | Semi-automatic | Dimension (L*W*H) | 3000*1400*2000mm |

Q: How long have you worked in this field?

A: Over 15 years.

Q:What's the delivery time?

A: Standard products will be 10-15days after receive your down payment or full payment.

Q: Can your factory produce products according to our drawings or samples?

A: Yes, of course we can.

Q: Are you manufacturer or trading company ?

A: We are a professional manufacturer.

Q: What is your factory's biggest advantage?

A: Technology is our core competitiveness.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan