[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

Suku cadang gratis|

Specifications

|

Unit | Y32-20T | Y32-63T | Y32-100T | Y32-200T | Y32-315T |

|

Nominal pressure

|

KN | 200 | 630 | 1000 | 2000 | 3150 |

|

Effective itinerary

|

mm | 300 | 300 | 400 | 600 | 800 |

|

Max openingheight

|

mm | 500 | 500 | 600 | 800 | 1200 |

|

Effective size of workbench (Left and right) |

mm | 400 | 500 | 660 | 800 | 1300 |

|

Effective size of workbench (Front and back) |

mm | 400 | 400 | 600 | 800 | 1200 |

|

The slide block descending speed |

mm/s | 15-30 | 15-30 | 60-80 | 80-100 | 80-100 |

|

The slide block return speed |

mm/s | 15-300 | 15-30 | 60-80 | 60-80 | 60-80 |

|

Motor power

|

KW | 1.1 | 3 | 7.5 | 11 | 15 |

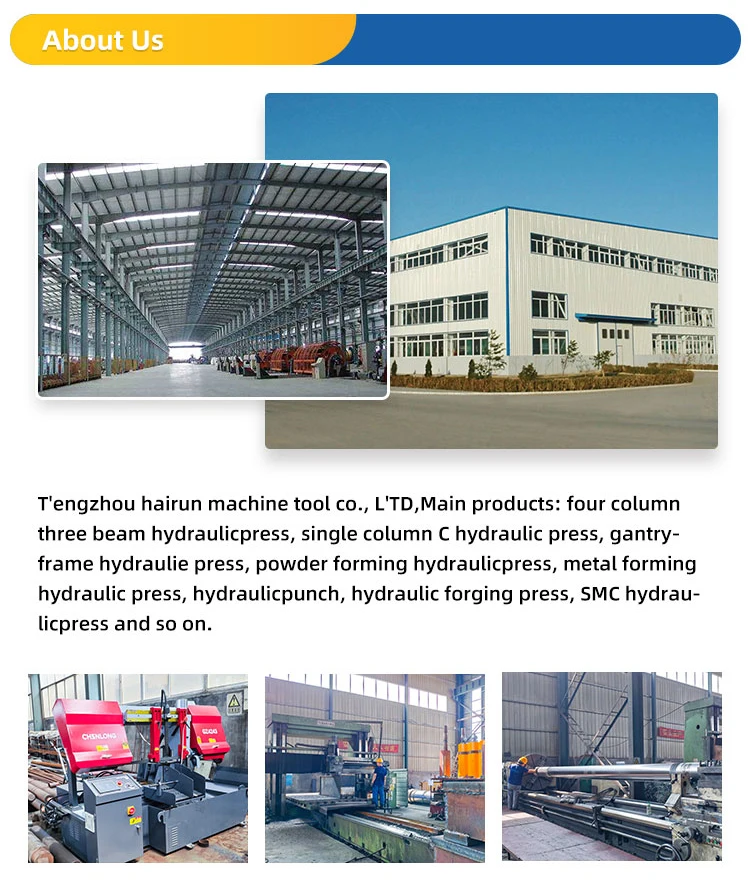

This equipment is produced by Tengzhou Hairun Machine Tool Co., Ltd. and is customized according to customer needs. If you have special requirements for the equipment, please let our customer service know clearly to avoid unnecessary trouble. Please provide the equipment's travel, opening, workbench size, and other requirements when inquiring. If you don't understand, you can also tell us what you do so that our engineers can provide you with a solution.

Scope of application: Hydraulic forming technology has a wide range of applications in industries such as automobiles, aviation, aerospace, and pipelines. It is mainly suitable for composite material molding processes such as fiberglass septic tanks, SMC, PP, PE plastic manhole covers, hotel bathroom chassis, hand sinks, washbasins, toilets, trash cans, and other products.

The stretching, bending, flanging, refrigerant, punching and other processes of metal materials are also applicable to calibration, pressing, powder products, abrasive products pressing and forming, as well as insulation material pressing and forming processes.

The applicable materials for hydraulic forming process include carbon steel, stainless steel, aluminum alloy, copper alloy, nickel alloy, etc. In principle, materials suitable for cold forming are all suitable for hydraulic forming process.

1:What products does your company mainly produce?

The main products:Four column three beam hydraulic press,Single column C hydraulic press,Gantry frame hydraulic machine,Powder forming hydraulic press,Metal forming hydraulic press machine,Hydraulic punch press,Hydraulic forging press,SMC hydraulic press machine, etc.

2:How canlchoose the most suitable machines ?

Please tell our salesperson your specifications so that we can select the best model for you, or you can choose the correct model.

You can also send us the product drawings, or provide us with photos and dimensions of the products you have made, and we will choose the most suitable machine for you.

3:How long does the customized equipment project take?

Depending on the tonnage parameters of the equipment, the construction period is approximately 45-60 days. Some equipment with inventory has a delivery time of around 15-30 days.

4:What is your trade terms?

A : FOB, CFR and ClF all acceptable

5:What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; lrrevocable LC at sight

6:Where is the address of your company

Tengzhou hairun machine tool co., LTD is located in southern shandong province,Hometown of Confucius and mencius, mozi.National highway 104 runs north and south,West of the weishan lake,To the north are Confucius palace and mount tai,Convenient transportation and developed industry.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.