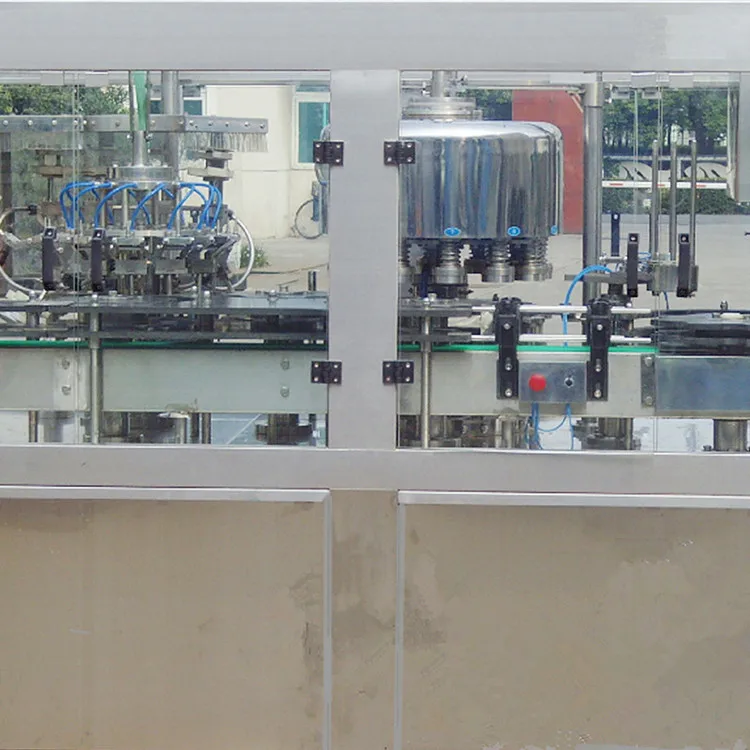

1. PLC secara otomatis menyelesaikan kontrol seluruh proses mesin pengisi 3-in-1 dari inlet botol hingga outlet botol.

2. Menggunakan operasi layar sentuh, kecepatan produksi, hitungan output kelas, kategori kesalahan, titik terjadinya kesalahan, dll. Ditampilkan

Di layar. Dan secara otomatis dapat menghitung waktu terjadinya kesalahan, kategori kesalahan dan informasi lainnya.

3. Komponen listrik utama terbuat dari produk merek terkenal di dunia untuk memastikan kinerja yang sangat baik dari seluruh mesin.

[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

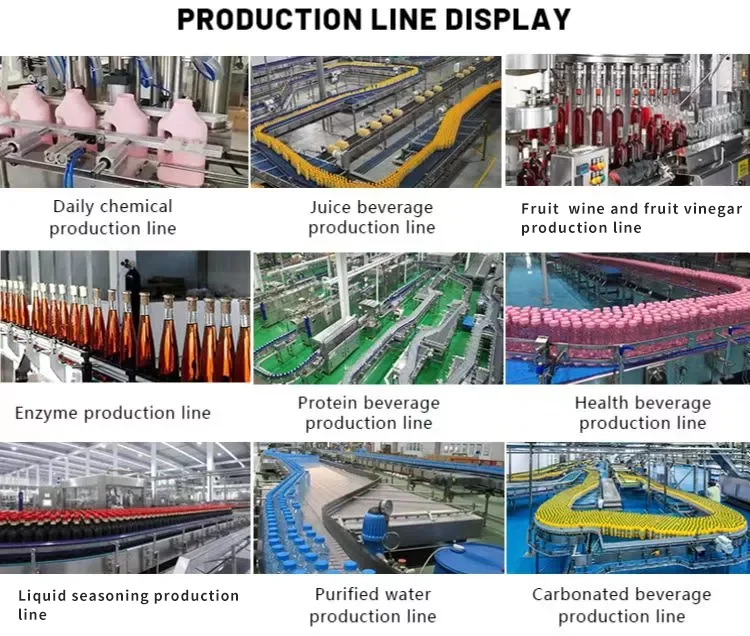

Mesin penyegel dapat diisi transparan hewan peliharaan otomatis untuk bir karbon minuman jus air Soda lembut minuman dan minyak

Mesin penyegel dapat diisi transparan hewan peliharaan otomatis untuk bir karbon minuman jus air Soda lembut minuman dan minyak