Suku cadang gratis

Suku cadang gratis

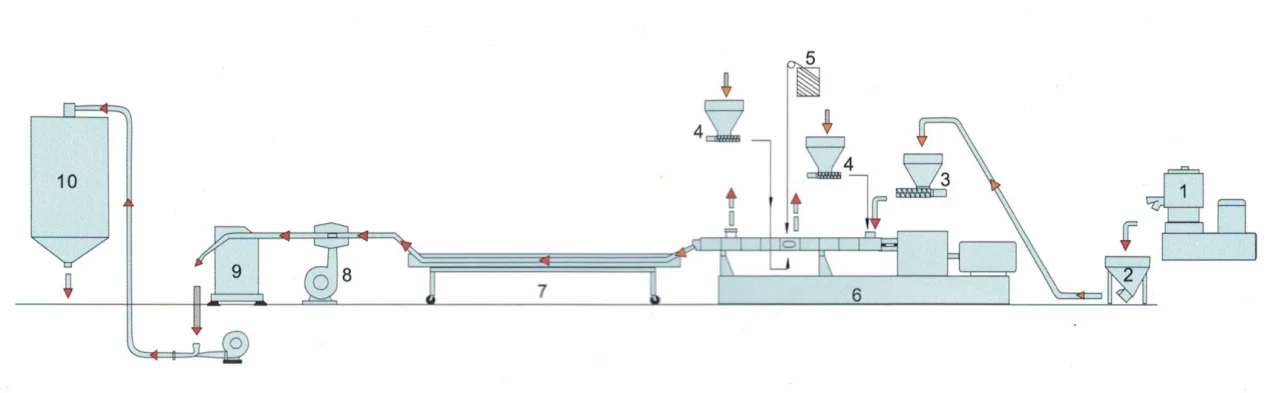

Lab Co-ratating Twin Screw Extruder Characteristics:

1.Easy dismantle and assemble.

2.Very small foot space, reduced working space.

3.Use less material for faster, cost-effective development.

4.Barrels and screw elements are designed as modulars, we configure the barrels and srew elements individually applications.

5.Easy cleaning and configuration changes.

6.Facilitate data collection and recording.

Type | D(mm) | Do/DI | L/D | rpm(max) | P(kw) | T/A3 | Q(kg/h) |

CTS-16C | 15.6 | 1.71 | 24~48 | 600 | 1.5 | 6.1 | 1~10 |

CTS-20C | 22 | 1.54 | 32~64 | 600 | 5.5 | 7 | 5~20 |

CTS-26C | 26 | 1.53 | 32~100 | 600 | 7.5 | 5.6 | 8~35 |

CTS-30C | 30.2 | 1.42 | 32~100 | 600 | 15 | 6.8 | 15~55 |

CTS-35C | 35.6 | 1.51 | 32~100 | 900 | 30 | 5.8 | 20~120 |

Nanjing Beyou Extrusion Machinery Co.,Ltd. is a professional rubber and plastic machinery manufacturer, mainly engaged in plastic extrusion machine as the core of the plastic modification equipment and related technology and engineering field of research and development and production of auxiliary machines. The main products are twin-screw extruder, single-screw extruder, PVB intermediate film production line equipment, glass fiber reinforced thermoplastics production line and self-developed underwater granulation system, which are widely used in various kinds of plastic and rubber materials, such as coloring, blending, filling, strengthening, stripping and recycling. According to different requirements of customers, we can provide appropriate solutions for customers.

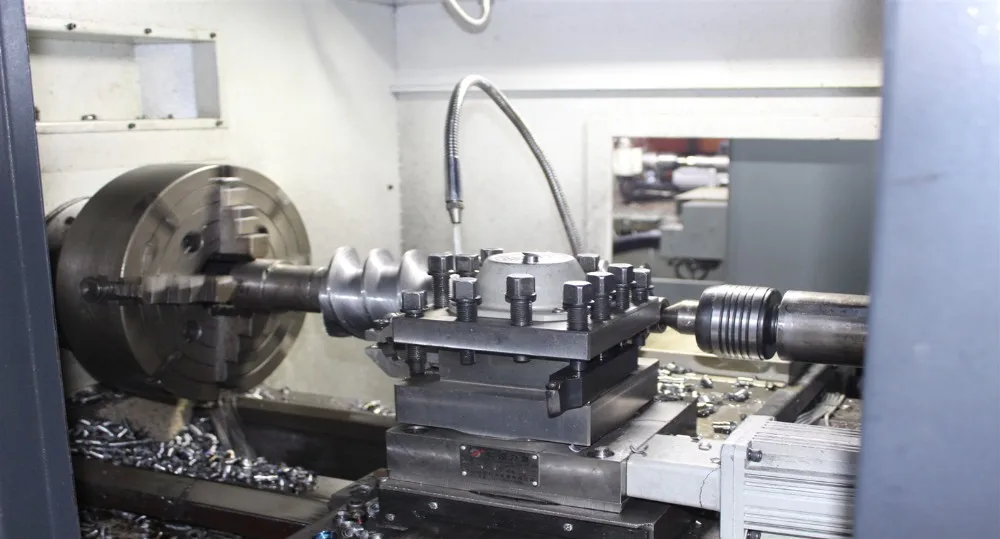

Our company leads the industry in either software or hardware. Now it has a high-quality R&D team and engineering team that have engaged in the field of twin-screw extruder for many years. We have equipped with standard workshops, various automated advanced processing equipment and modern quality testing center. Our company invests huge sums of money in R&D every year to cooperates customer's development requirements, and dedicated to provide customers with technical design, machine assembly and on-site debugging services, strive to create greater economic and social benefits for customers.

Packing Details: Wood cases or sea worthy packing.

Delivery Details: Within 8 weeks from the receipt of your down payment.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.