A fabric building is a type of structure that uses fabric, usually made of durable materials like polyethylene, PVC, or other

synthetic textiles, as its primary exterior covering. These buildings can be used for a variety of applications, including

agricultural storage, industrial facilities, sports complexes, and event spaces. ### Key Features of Fabric Buildings:

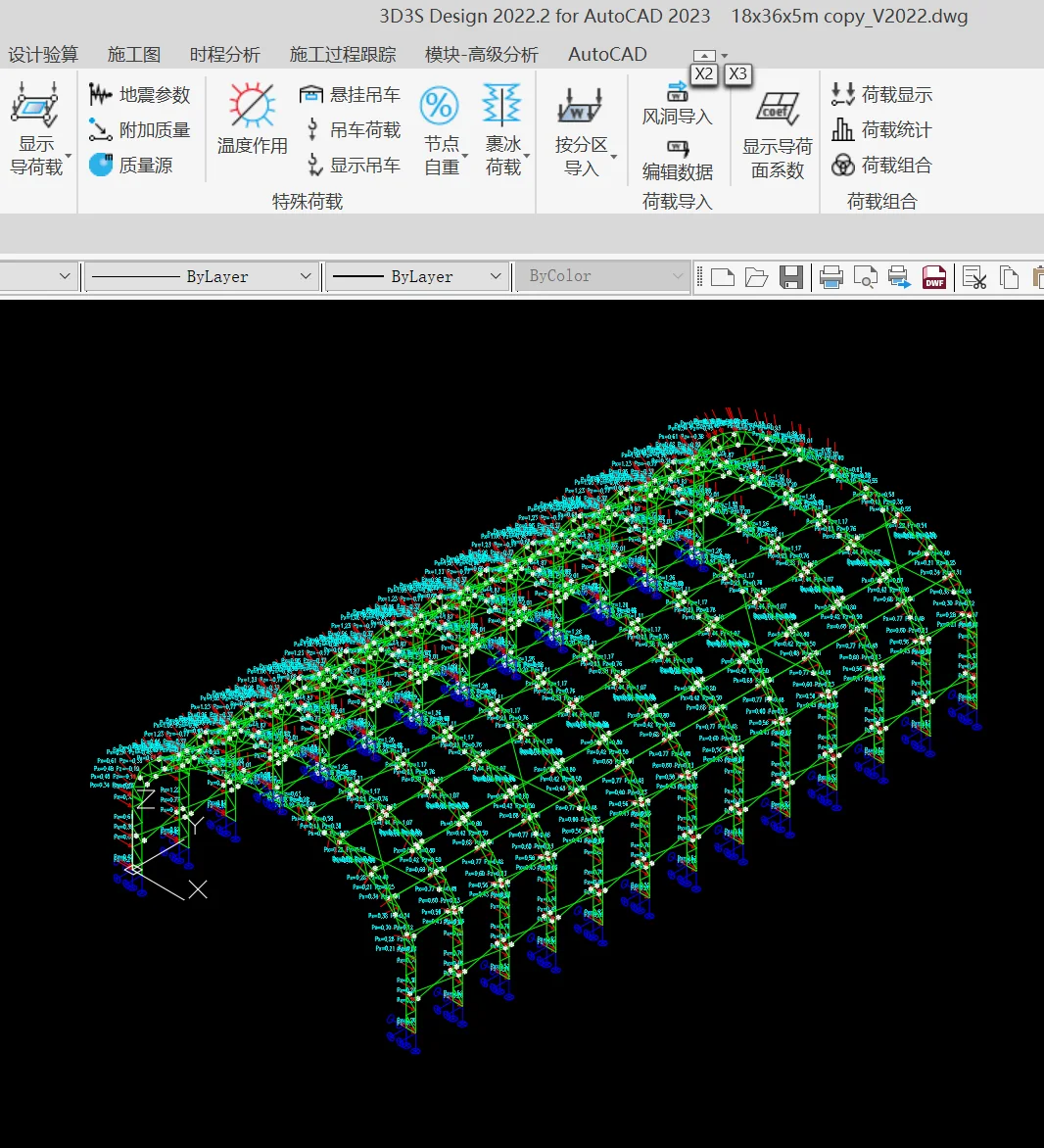

1.**Structure**:

Fabric buildings typically have a frame made of steel, aluminum, or other materials, which supports the fabric

covering. The design can be temporary or permanent, depending on the intended use.

2. **Lightweight**:

The materials used in fabric buildings are generally lighter than traditional building materials, making them easier to transport and install.

3.**Versatile Designs**:

Fabric buildings can be customized in size, shape, and layout to fit specific needs, making them suitable

for a wide range of functions.

4. **Natural Lighting**:

Many fabric structures allow for natural light to enter, reducing the need

for artificial lighting and creating a more pleasant environment.

5. **Cost-Effective**:

They can be more affordable to construct and maintain than traditional buildings, particularly for large spaces.

### Advantages of Fabric Buildings:

1. **QuickInstallation**:

Fabric buildings can often be erected in a shorter time frame compared to conventional structures, making them

ideal for urgent needs.

2. **Energy Efficiency**:

he insulation properties of certain fabric materials can help maintain

temperature, potentially reducing heating and cooling costs.

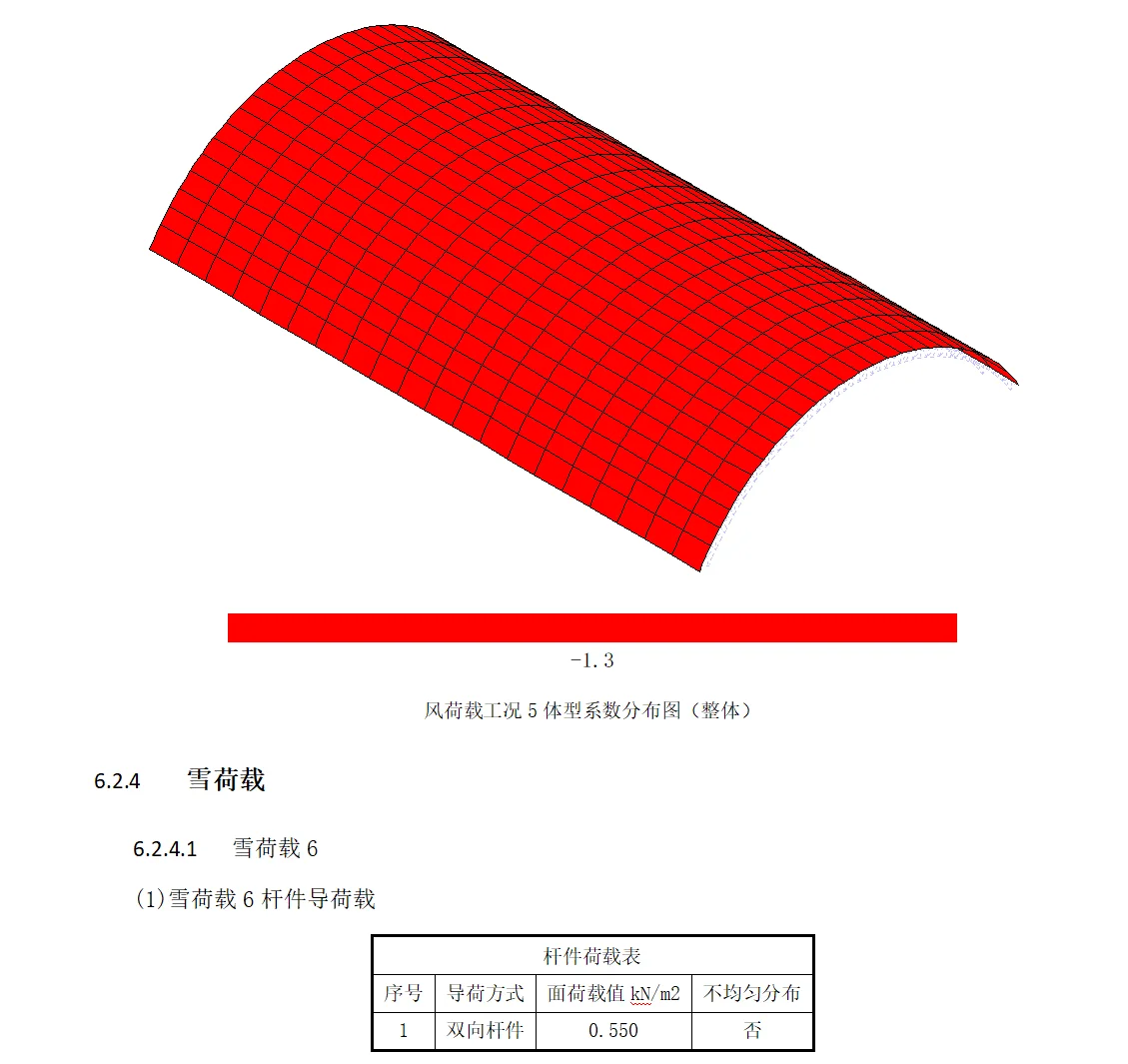

3. **Durability**:

High-quality fabric can withstand different weather conditions, including wind, rain, and snow, depending on the design and construction.

4. **Flexibility**:

Fabric buildings can be designed to be demountable, allowing for relocation or reconfiguration as needs change.

5. **Low Maintenance**:

Thesestructures typically require less maintenance than traditional buildings, and the materials are resistant to corrosion.

6.**Sustainability**:

Many fabric buildings can be designed with eco-friendly materials and practices in mind, contributing to

sustainable construction efforts.

7. **Enhanced Airflow**:

The design often promotes better ventilation, which can be beneficial

for certain applications, such as agricultural uses.

### Applications of Fabric Buildings: -

**Agricultural Use**:

Storage forhay, equipment, and livestock shelters. -

**Industrial Use**:

Warehousing, manufacturing, and workshop spaces. -

**Recreational Use**:

Sports facilities, gymnasiums, and event venues. -

**Commercial Use**:

Retail spaces, showrooms, and temporary structures

for events. Overall, fabric buildings offer a versatile and efficient solution for a wide range of applications, combining

functionality with cost-effectiveness.