[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

Suku cadang gratisComplete orange/apple/mango processing mahine/production line /pomegranate juice machine

Overview of Juice Production Line

The juice production line refers to the entire automated production process from the processing of fruit raw materials to the final packaging of finished products. It includes multiple key steps and technical equipment to ensure product quality and safety, while improving production efficiency. The following are the main components and process flow of the juice production line:

1. Raw material reception and cleaning

Fruit inspection: Conduct quality checks on the purchased fruits to ensure their freshness and harmlessness.

Cleaning and disinfection: Use specialized cleaning equipment to remove soil, pesticide residues, and other impurities from the surface of fruits, ensuring hygiene standards.

2. Peel, core removal, and slicing

Peeling machine: using mechanical or chemical methods to remove the skin.

• Nucleator: For fruits with nuclei (such as peaches and plums), use an automatic nucleus remover.

Slicer: Cut the whole fruit into blocks or slices of appropriate size for subsequent processing.

3. Juice extraction

Spiral press: Extracting juice through spiral squeezing, suitable for a variety of fruits.

• Beater: For some juices that require fiber retention (such as orange juice), a beater can be used.

4. Filtering and clarification

• Coarse filtration: preliminary removal of large particulate matter.

• Fine filtration: Use a microporous filter to further purify the juice, removing suspended solids and fine particles.

• Clarifier: Adding natural clarifying agents helps precipitate impurities, making the juice clearer and more transparent.

5. Sterilization and concentration

• Heat treatment: High temperature instant sterilization (HTST) or ultra-high temperature instant sterilization (UHT) is used to effectively kill microorganisms and extend shelf life.

• Concentration: Reduce moisture content through evaporation or other physical methods, improve storage stability, and reduce transportation costs.

6. Blending and Mixing

• Ingredient system: Add ingredients such as water, sugar, and acidifiers according to the formula requirements to adjust the taste and nutritional content.

Homogenization: Use a high-pressure homogenizer to evenly distribute various ingredients, improving taste and stability.

7. Filling and sealing

Aseptic filling line: The filling process is completed in a sterile environment to ensure product hygiene and safety.

Sealing machine: Choose the appropriate sealing method according to different packaging forms, such as screw cap, can sealing, heat shrink film, etc.

8. Packaging and palletizing

Labeling machine: Label each bottle or box of juice with brand information, production date, etc.

Packing machine: Load finished products into cardboard boxes or other containers for easy storage and transportation.

Stacking machine: Automatically stacks the packaged boxes neatly and prepares them for shipment.

9. Quality control

Online detection: Quality monitoring points are set up at various production stages to monitor the physical and chemical indicators and microbial conditions of products in real time.

• Laboratory analysis: Regular sampling and testing to ensure that the final product meets national standards and internal control standards of the enterprise.

Summary

The juice production line is a complex and precise process that involves multiple procedures and technical equipment. Through scientific and rational process design and strict quality management, high-quality, safe and healthy juice products can be produced to meet market demand and enhance the competitiveness of enterprises.

The main equipment of the juice production line involves multiple key steps, each of which requires specific equipment to ensure efficient, hygienic, and high-quality production. Here are some of the main equipment in the juice production line:

1. Raw material processing equipment

Cleaning machine: used to remove soil, pesticide residues, and other impurities from the surface of fruits. Common types include drum cleaning machines, bubble cleaning machines, etc.

Peeling machine: using mechanical or chemical methods to remove the skin. For example, the alkaline peeler commonly used for citrus fruits and the friction peeler commonly used for apples.

• Core remover: specifically designed to remove the core of fruits with cores, such as peaches and plums.

Slicer/slicer: Cut the whole fruit into blocks or slices of appropriate size for subsequent processing.

2. Juice extraction equipment

Spiral press: Extracting juice through spiral squeezing, suitable for various fruits such as apples, oranges, etc.

• Beater: For juice that requires fiber retention (such as orange juice), a beater can be used to mix the pulp and juice evenly.

Centrifugal juicer: uses the centrifugal force generated by high-speed rotation to separate juice and fruit residue, suitable for various fruits, especially berries.

3. Filtering and clarification equipment

Coarse filter: preliminary removal of large particles such as nuclei and fruit pulp.

Fine filter: Use a microporous filter to further purify the juice, remove suspended solids and small particles, and ensure that the juice is clear and transparent.

• Clarification tank: Adding natural clarifying agents to help precipitate impurities, making the juice clearer and more transparent.

4. Sterilization and concentration equipment

Heat exchanger: used to heat fruit juice for high-temperature instant sterilization (HTST) or ultra-high temperature instant sterilization (UHT), effectively killing microorganisms and extending shelf life.

Evaporator: Reduce moisture content through evaporation or other physical methods, improve storage stability, and reduce transportation costs.

5. Equipment allocation and mixing

• Ingredient tank: Add ingredients such as water, sugar, and acidifier according to the formula requirements to adjust the taste and nutritional content.

High pressure homogenizer: evenly distribute various components, improve taste and stability, and prevent layering.

6. Filling and sealing equipment

Aseptic filling machine: Complete the filling process in a sterile environment to ensure product hygiene and safety.

Sealing machine: Choose the appropriate sealing method according to different packaging forms, such as screw cap, can sealing, heat shrink film, etc.

7. Packaging and palletizing equipment

Labeling machine: Label each bottle or box of juice with brand information, production date, etc.

Packing machine: Load finished products into cardboard boxes or other containers for easy storage and transportation.

Stacking machine: Automatically stacks the packaged boxes neatly and prepares them for shipment.

8. Quality control equipment

Online detection device: Quality monitoring points are set up at various production stages to monitor the physical and chemical indicators and microbial conditions of products in real time.

Laboratory analytical instruments: Regular sampling and testing are conducted to ensure that the final product meets national standards and internal control standards of the enterprise.

Summary

These devices together form a complete juice production line, ensuring that every step from fruit raw materials to final products can be efficiently and safely carried out. Through scientific and rational process design and strict quality management, high-quality, safe and healthy juice products can be produced to meet market demand and enhance the competitiveness of enterprises.

Technical Data For apple processing line

|

Raw material |

Fresh fruit apple/pear |

|

End product |

Transparent juice,cloudy juice, nfc and concentrated juice,cider and cider vinegar etc |

|

Processing capacity |

60-1500 tons/day |

|

Output percentage |

60-75% |

|

Solid content in NFC concentrated juice content |

10-12Brix |

|

65-72Brix |

|

|

End package |

Aseptic bag/gable top box /PET bottle |

The customized process of juice production line requires detailed planning based on specific needs, budget, and production scale to ensure the efficiency, flexibility, and economy of the production line. The following are the main steps for customizing a juice production line:

1. Requirement analysis

• Clarify product type: Determine the type of juice to be produced (such as orange juice, apple juice, mixed juice, etc.), and whether it is necessary to retain fruit pulp fibers.

Capacity requirements: Determine the hourly or daily output based on market demand and sales forecasts.

Quality standards: Understand the quality standards and regulatory requirements of the target market (such as food safety standards, organic certification, etc.).

Special requirements: Consider whether there are any special requirements, such as sterile filling, environmental requirements, automation level, etc.

2. Process design

• Raw material processing: Select suitable cleaning, peeling, nucleating, and slicing equipment to ensure the quality of raw material pretreatment.

• Juice extraction method: Select appropriate juice extraction equipment based on the characteristics of the fruit (such as screw press, beater, centrifugal juicer, etc.).

• Filtration and clarification: Determine the process steps for coarse filtration, fine filtration, and clarification, and select appropriate filters and clarification tanks.

Sterilization and concentration: Choose suitable heat treatment and concentration methods (such as HTST, UHT, evaporation concentration, etc.).

• Blending and mixing: Select the ingredient system and homogenization equipment according to the formula requirements.

• Filling and packaging: Determine the filling method (such as bottled, boxed, bagged) and sealing equipment, and select labeling, boxing, and palletizing equipment.

3. Equipment selection

Supplier selection: Look for reliable equipment suppliers, compare technical parameters, prices, and service support of different brands.

Equipment configuration: Select suitable equipment models and specifications based on process design to ensure compatibility and matching of equipment in each stage.

Installation space: Evaluate the spatial layout of the production workshop, arrange the placement of equipment reasonably, and ensure easy operation and smooth logistics.

4. Engineering Design

• Factory layout: Draw a detailed factory floor plan, indicating the location of each equipment, pipeline direction, and logistics channels.

Electrical design: Design electrical control systems, including power supply, distribution cabinets, control panels, etc.

• Pipeline design: Design juice conveying pipelines to ensure no cross contamination and compliance with hygiene standards.

Ventilation and Drainage: Design a well-designed ventilation and drainage system to maintain a clean and hygienic workshop environment.

5. Project implementation

Equipment procurement: Sign equipment procurement contracts, arrange equipment production and transportation.

Installation and debugging: Organize a professional team to install and debug equipment to ensure the normal operation of each device.

Personnel training: Provide skill training to operators to familiarize them with equipment operation and maintenance procedures.

• Trial production: Conduct small-scale trial production, check the operation status of the production line, adjust and optimize process parameters.

6. Acceptance and delivery

Performance testing: Conduct comprehensive performance testing to verify whether the production line meets the predetermined production capacity, product quality, and safety standards.

• Document transfer: Organize and transfer all relevant technical documents, operation manuals, and maintenance guidelines.

After sales service: Negotiate after-sales service terms with suppliers to ensure timely technical support and maintenance services for the production line during use.

Summary

Customizing a juice production line is a complex process that involves multiple stages and technical details. Through scientific and rational planning and rigorous implementation, an efficient, stable, and safe juice production line can be established to meet the production and market requirements of enterprises.

Pre sales services

Post sales services

1. Equipment warranty period: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2. Maintenance and upkeep services: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3. Accessory supply: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4. Training services: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5. Installation and debugging: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.

1 ) Q: How can we visit your factory?

A: If you come from abroad, air to shanghai airport, then we can pick you up at airport.

2) Q: How do you ensure the quality of your products?

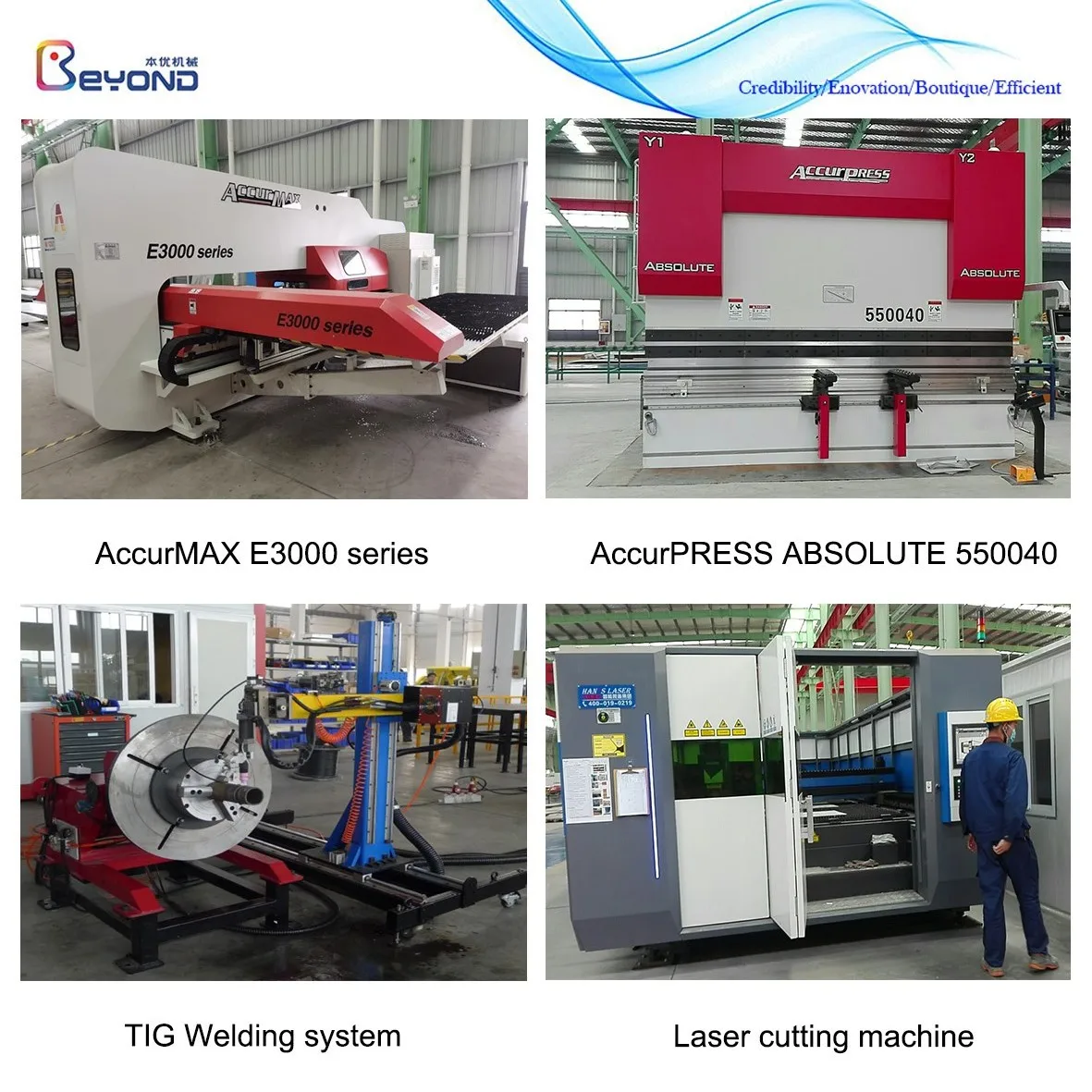

A: Our Company is a state owned enterprise with more than 16 years experience , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.

3) Q: What payment methods your company accept?

A: We accept most of the payment methods , but mainly accept T/T, L/C at sight .

4) Q: How long is the warranty time for your products?

A: Our officially promised warranty time is 12 months after commissioning .

5) Q: I am new in this field,can you supply us turnkey services?

A: YES.We can supply all the system including Market Analysis/Product Analysis/Location Choice/Processing Flow Design/Equipment Layout Design/Building Design direction/Equipment mode selection/Equipment Manufacturing/Equipment Mounting/Equipment Debugging/Worker Training.

6) Q: I haven't done business with you company before, how can I trust your company ?

A: Our company has been in Cooig.com for 14 years, which is longer than most of our fellow suppliers, we have been golden suppliers for years. What ' s more, we have got quite a lot authority certificates, for example, CE, ISO9001, Cooig onsite check certificate.

7) Q: What ' s the shipment terms and delivery time of your company?

A: Well, the delivery time depend on the quantity of your order. Usually is 20 days . For some customized machine 30 days is necessary.

8) Q: Can you supply OEM services?

A: Yes,we have our R&D team,and we have more than 400 workers with workshop area 75000 square meters.

9) Q: Do you give any Discount?

A: I will surely try my best to help you get those by the best price and good service at the same time.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.