* The sharp cutting edge ensures precise cutting of aluminum and reduces burrs, making the machined surface as smooth as amirror.

* The carefully designed cutting edge angle realizes efficient cutting and greatly improves processing efficiency.

Product Name | Carbide End Mill For Aluminium |

Size | Diameter 1-25mm / Customize |

Brand Name | JYTOOLS |

Flute | 3Flutes |

Precision | High Precision |

Customized support | OEM, ODM, OBM |

Controlling Mode | CNC Tooling System |

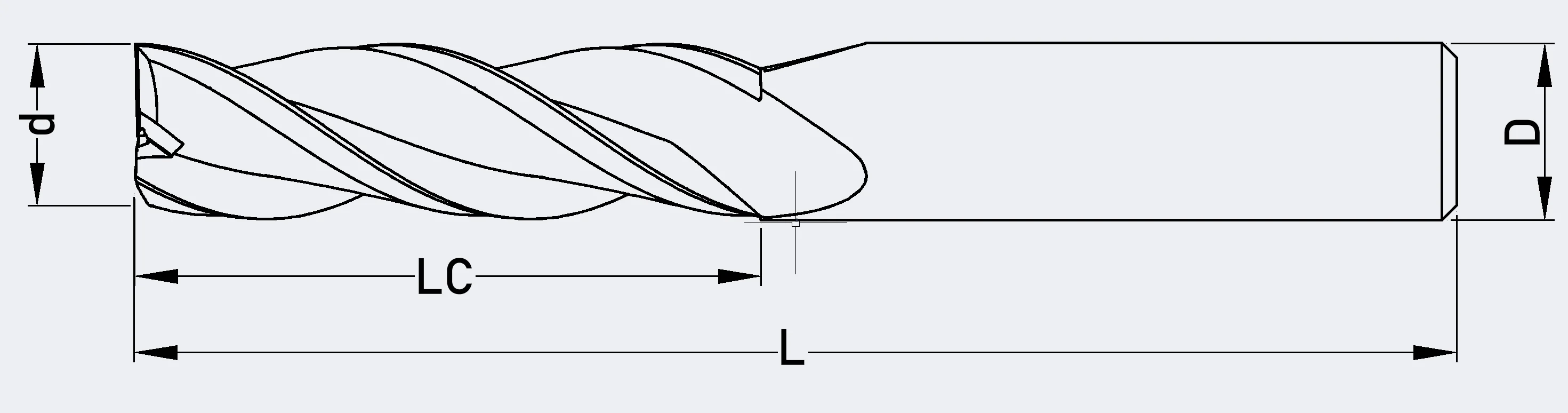

MODEL | Specification | Flutes | ||||||

d | LC | D | L | |||||

1.0*3*4*50*3F | 1 | 3 | 4 | 50 | 3F | |||

1.5*4.5*4*50*3F | 1.5 | 4.5 | 4 | 50 | ||||

2.0*6*4*50*3F | 2 | 6 | 4 | 50 | ||||

2.5*7*4*50*3F | 2.5 | 7 | 4 | 50 | ||||

3.0*9*4*50*3F | 3 | 9 | 4 | 50 | ||||

3.0*9*3*50*3F | 3 | 9 | 3 | 50 | 3F | |||

3.5*10*4*50*3F | 3.5 | 10 | 4 | 50 | ||||

4*12*4*50*3F | 4 | 12 | 4 | 50 | ||||

4*15*4*75*3F | 4 | 15 | 4 | 75 | ||||

4*20*4*100*3F | 4 | 20 | 4 | 100 | ||||

5*15*5*50*3F | 5 | 15 | 5 | 50 | ||||

5*15*6*50*3F | 5 | 15 | 6 | 50 | ||||

6*18*6*50*3F | 6 | 18 | 6 | 50 | ||||

6*25*6*75*3F | 6 | 25 | 6 | 75 | ||||

6*30*6*100*3F | 6 | 30 | 6 | 100 | ||||

8*24*8*60*3F | 8 | 24 | 8 | 60 | 3F | |||

8*25*8*75*3F | 8 | 25 | 8 | 75 | ||||

8*35*8*100*3F | 8 | 35 | 8 | 100 | ||||

10*30*10*75*3F | 10 | 30 | 10 | 75 | ||||

10*40*10*100*3F | 10 | 40 | 10 | 100 | ||||

12*30*12*75*3F | 12 | 30 | 12 | 75 | ||||

12*45*12*100*3F | 12 | 45 | 12 | 100 | ||||

14*35*14*80*3F | 14 | 35 | 14 | 80 | ||||

14*45*14*100*3F | 14 | 45 | 14 | 100 | 3F | |||

16*45*16*100*3F | 16 | 45 | 16 | 100 | ||||

18*45*18*100*3F | 18 | 45 | 18 | 100 | ||||

20*45*20*100*3F | 20 | 45 | 20 | 100 | ||||

6*35*6*150*3F | 6 | 35 | 6 | 150 | ||||

8*50*8*150*3F | 8 | 50 | 8 | 150 | ||||

10*55*10*150*3F | 10 | 55 | 10 | 150 | ||||

12*60*12*150*3F | 12 | 60 | 12 | 150 | ||||

14*65*14*150*3F | 14 | 65 | 14 | 150 | ||||

16*70*16*150*3F | 16 | 70 | 16 | 150 | ||||

18*70*18*150*3F | 18 | 70 | 18 | 150 | ||||

20*70*20*150*3F | 20 | 70 | 20 | 150 | ||||

7*24*8*60*3F | 7 | 24 | 8 | 60 | 3F | |||

9*30*10*75*3F | 9 | 30 | 10 | 75 | ||||

11*30*12*75*3F | 11 | 30 | 12 | 75 | ||||

13*40*14*100*3F | 13 | 40 | 14 | 100 | ||||

15*45*16*100*3F | 15 | 45 | 16 | 100 | ||||

6*35*6*200*3F | 6 | 35 | 6 | 200 | ||||

8*50*8*200*3F | 8 | 50 | 8 | 200 | ||||

10*55*10*200*3F | 10 | 55 | 10 | 200 | ||||

12*60*12*200*3F | 12 | 60 | 12 | 200 | ||||

14*60*14*200*3F | 14 | 60 | 14 | 200 | ||||

16*70*16*200*3F | 16 | 70 | 16 | 200 | ||||

20*70*20*200*3F | 20 | 70 | 20 | 200 | ||||

Harapkan pesanan Anda dikirim sebelum tanggal yang dijadwalkan atau dapatkan kompensasi keterlambatan sebesar 10%.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan uang Anda kembali untuk pengiriman yang terlewat dan produk yang cacat atau rusak, ditambah pengembalian lokal gratis untuk produk cacat