[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

Suku cadang gratis

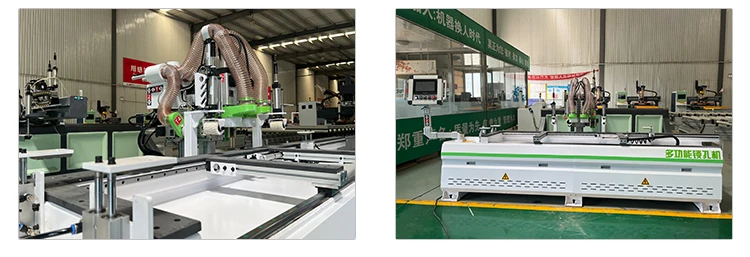

Model peralatan | Mesin lubang kunci CNC multifungsi |

Fungsi | Lubang kunci pintu, engsel, lubang pemasangan perangkat keras, pemrosesan slot, lubang engsel (engsel tidak terlihat, engsel multi-lapisan, dll.), penutup pintu, dll. |

Spesifikasi pemrosesan panel pintu | Lebar pemrosesan: tak terbatas Panjang pengolahan: panjang 1700mm-panjang 2800mm |

Perlengkapan tetap | Dapat disesuaikan secara manual |

Struktur badan pesawat | Konstruksi baja selesai tugas berat |

Struktur meja | Mekanisme konveyor tembus tipe |

Poros daya | Poros terbuka T1 3,5 KW T2 poros alur penggilingan atas 3,5 KW T3 sisi penggilingan alur spindel 6 KW T4 poros modifikasi sisi 2,2 KW |

Sistem kontrol | Sistem kontrol gerakan Lorenzo |

Lari | Presisi tinggi 30/25/20 persegi |

Mode transmisi | Rak dan lead screw |

Inverter | 7,5 kW terbaik |

Peredam | Peredam roda gigi planet Taiwan |

Penggerak Motor | Navigasi servo 750w * 3 Z sumbu dengan rem |

Perangkat penentuan posisi | Ya |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.