[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

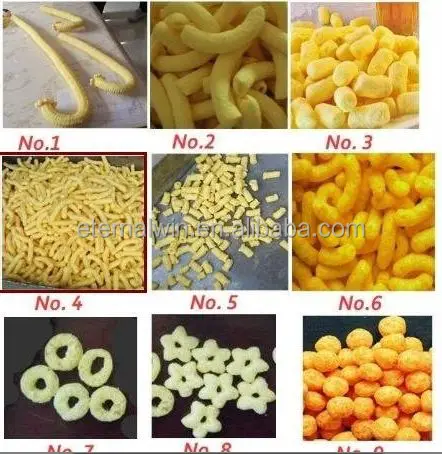

Corn puff snack food machine adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through brication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Our extrusion machines can produce various uncoated, coated or filled cereal based snacks – with a wide variety of recipes and shapes. corn puff snack extruder machine adopt twin-screw extrusion technology and are highly flexible. They can be easily modified to process new products such as filled products, corn chips snacks or bread crumb snacks, with just easily adding some auxiliary equipment.

Model | Capacity(kg/h) | Main power(KW) | cutting power(kw) | Feeder power(KW) | Screw diameter(mm) |

GAS-45A | 30-40 | 4/5.5 | 0.4 | 0.4 | Φ40 |

GAS-45B | 50-60 | 7.5 | 0.4 | 0.4 | Φ40 |

GAS-55 | 60-80 | 7.5 | 0.4 | 0.4 | φ50 |

GAS-65 | 120-150 | 15 | 0.55 | 0.55 | φ60 |

GAS-75 | 200-250 | 18.5 | 0.55 | 0.55 | φ70 |

GAS-85 | 250-300 | 22 | 0.75 | 0.75 | φ80 |

1. The cutting structure is very advanced with cutter shaft fixed spring to cut to realize infinitely speed change; the final output product can be cut freely in different length according to requirement.

2. Novel design, unique, simple structure, easy to install and operate.

3. The Screw is made of special wear-resisting No38 chromium aluminum molybdenum after tempering, heating and formed, its with wear-resisting and long life.

4. In order to ensure quality and capacity, there is special pressurization die device. And the electric heating device improves the feed expansion rate.

5. The main bearing is from Japanese and Sweden SKF bearing to ensure its safety. The main motor is Y-Series three phrase motor.

Still have questions on Extruded Corn Rice Cereal Snacks Machine Production Line Automatic Puffs Extruder Manufacturing Machine? Pls contact me,

Name: Ivy Xu

Whatsapp: +86 13525093936

Wechat: +86 13525093936

Pesanan tiba sebelum jadwal, atau dapatkan kompensasi 10% dari harga pesanan jika pengiriman telat.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.