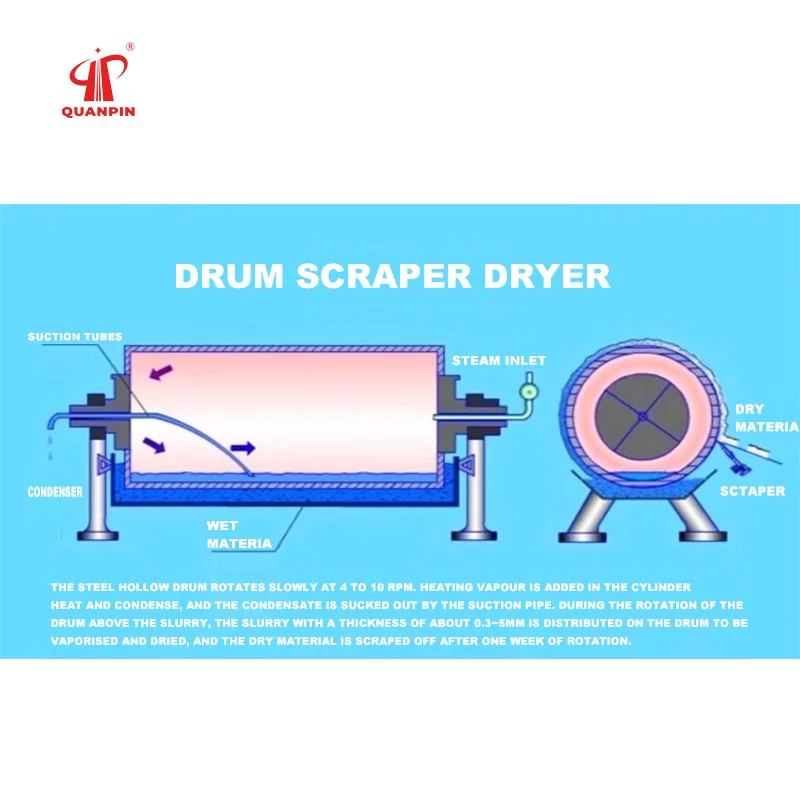

(1) High thermal efficiency:

The heat supplied in the cylinder, in addition to a small amount of heat radiation and the end cover of the cylinder body part of the heat loss, most of the heat is used in the wet part of the gasification, the thermal efficiency can be as high as 70~80%.

(2) Drying rate is large:

The heat and mass transfer process of the wet material film on the cylinder wall, from inside to outside, in the same direction, the temperature gradient is large, so that the material film surface to maintain a high evaporation intensity, generally up to 30~70kg.

(3) The drying quality of the product is stable:

Roller heating mode is easy to control, the temperature inside the cylinder and the heat transfer rate of the wall can be kept relatively stable, so that the material film can be dried in a stable state of heat transfer, and the quality of the product can be guaranteed.

(4) Wide range of application:

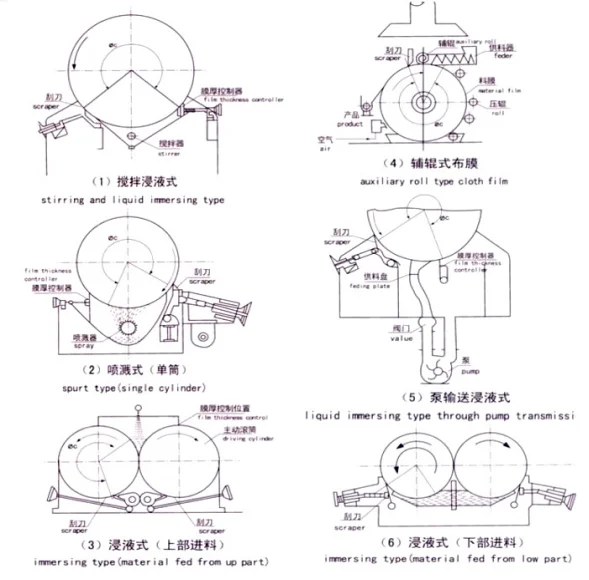

The liquid phase material using drum drying, must have mobility, adhesion and thermal stability of the form of the material can be a solution, non-homogeneous suspension, emulsion, sol-gel and so on. For pulp, textiles, celluloid and other band materials can also be used.

(5) the production capacity of a single machine:

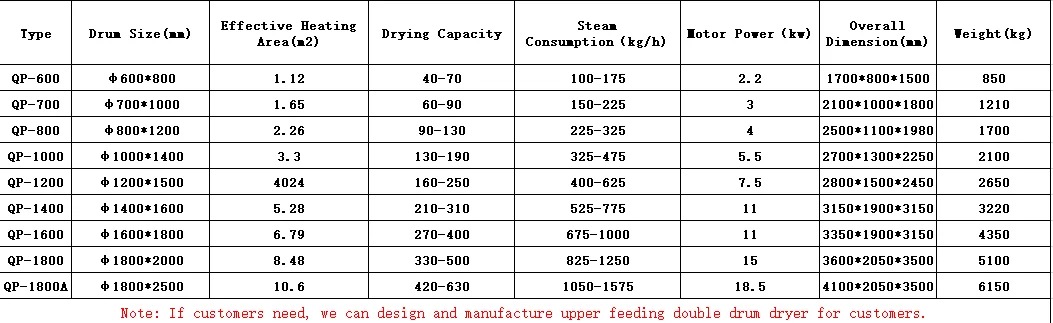

Restricted by the size of the cylinder General drum dryer drying area, should not be too large. The drying area of a single cylinder, rarely more than 12 m2. The same specifications of the equipment, the ability to deal with the liquid material, but also by the nature of the liquid material, moisture content control, film thickness, drum speed and other factors, the magnitude of the change is large, generally in the range of 50 to 2000kg / h. The drying area of a single cylinder, seldom more than 12m2.

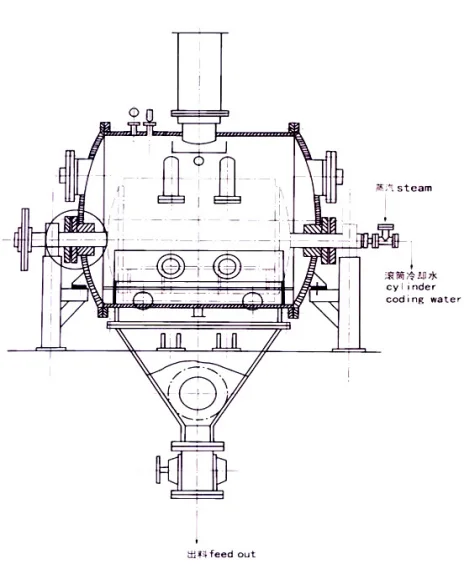

(6) heating medium is simple:

Commonly used saturated water vapour, pressure range of 2~6kgf/com2, rarely more than 8kgf/cm2. For some of the requirements of drying materials at low temperatures, hot water can be taken as a heat medium: to dry materials at higher temperatures, can also be used as a heat medium or high-boiling organic as a heat medium.

Suku cadang gratis

Suku cadang gratis