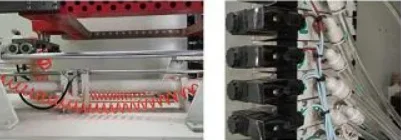

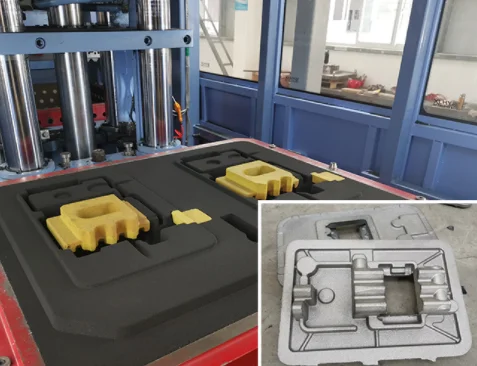

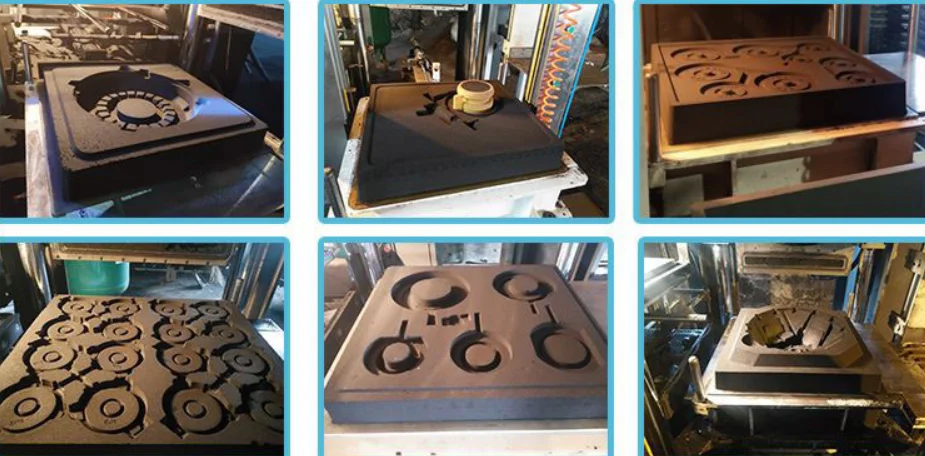

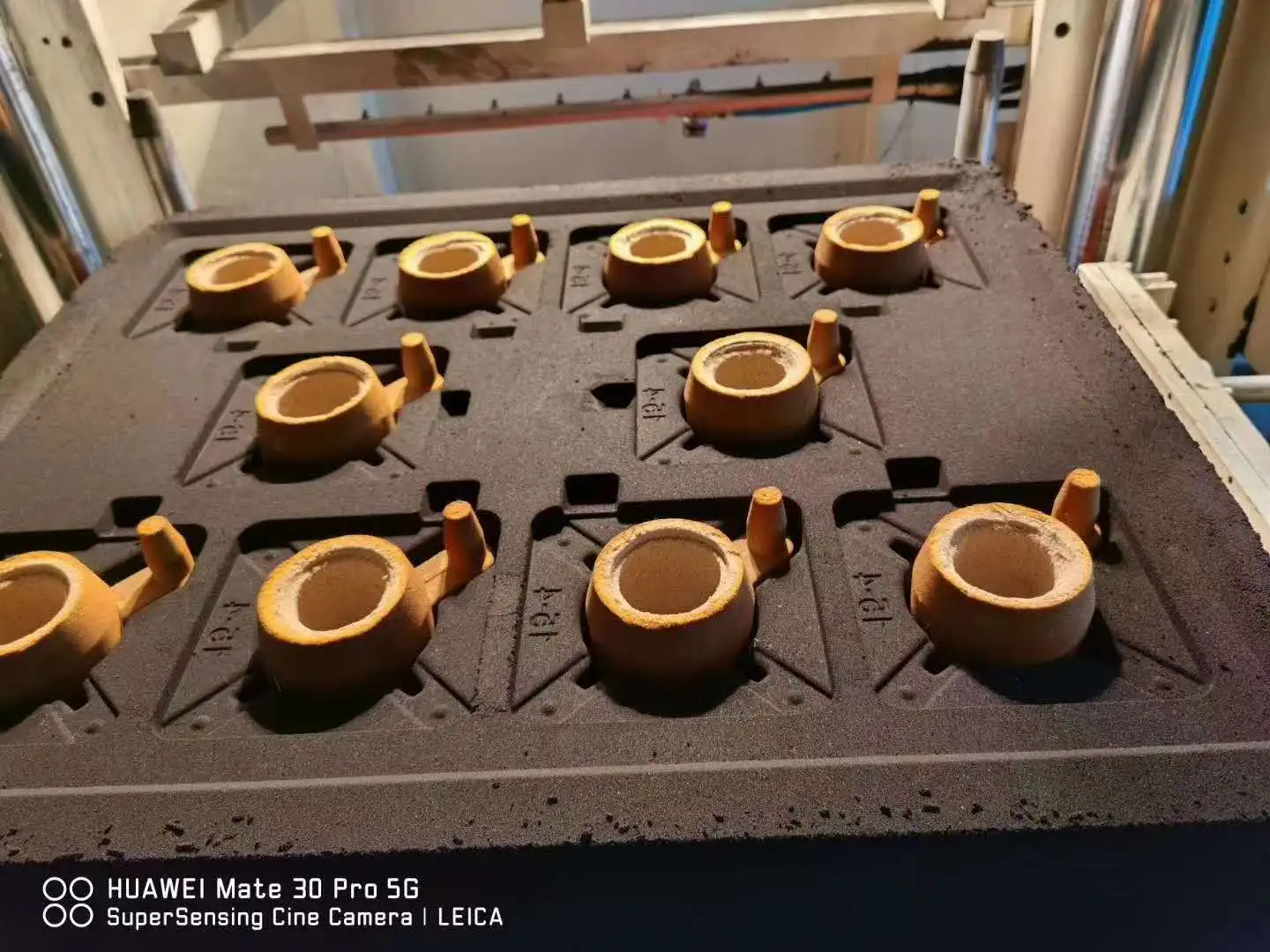

Casting machine it's main function:

Sand filling, the loose molding sand into the sand box; Compacting molding sand, through shaking, compaction, shaking pressure, shooting pressure and other different methods to compact the loose molding sand in the sand box, so that the sand has the necessary strength in the process of handling and pouring; Mold, using different mechanisms to remove the shape from the compacted sand mold.