[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

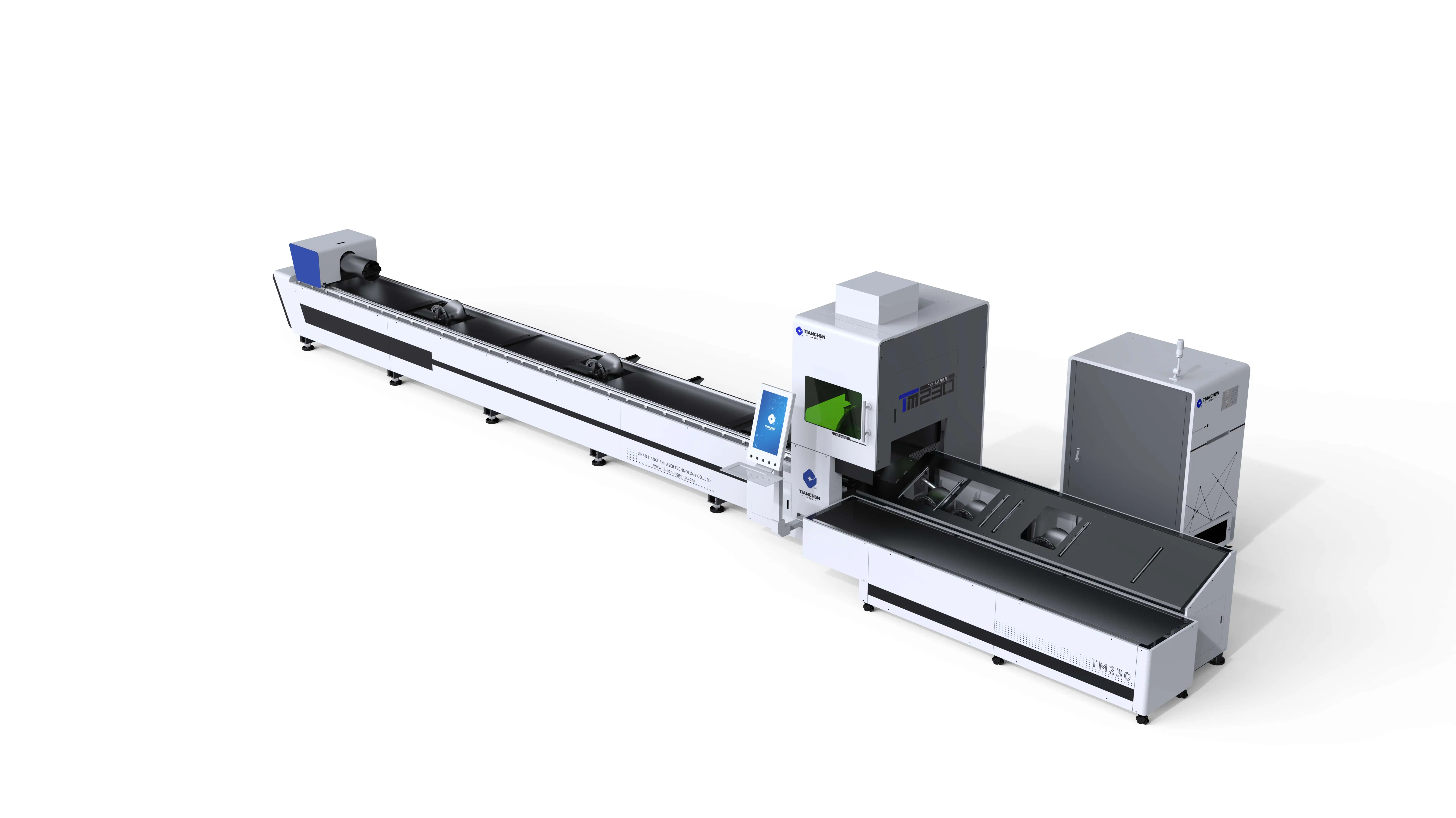

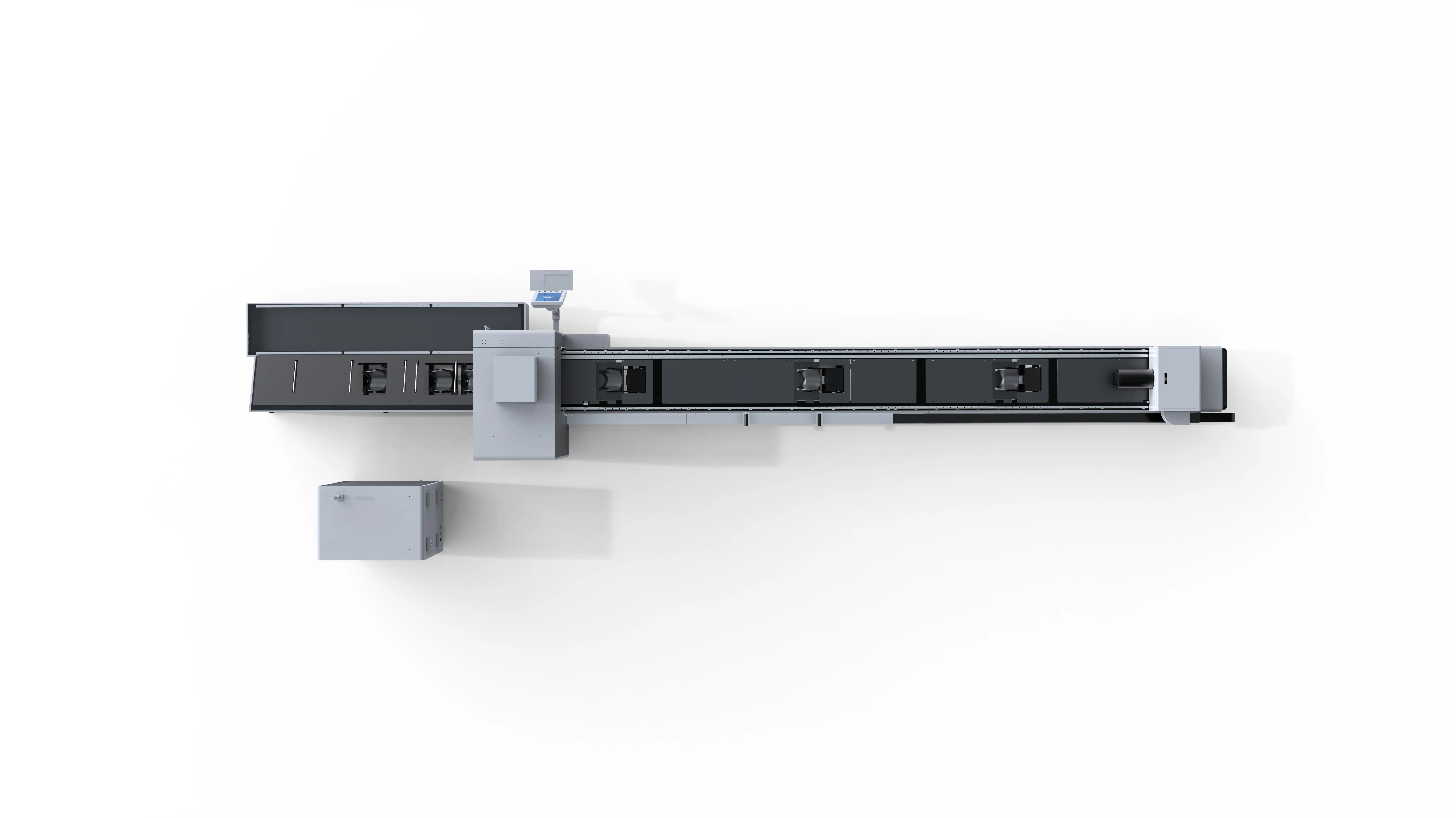

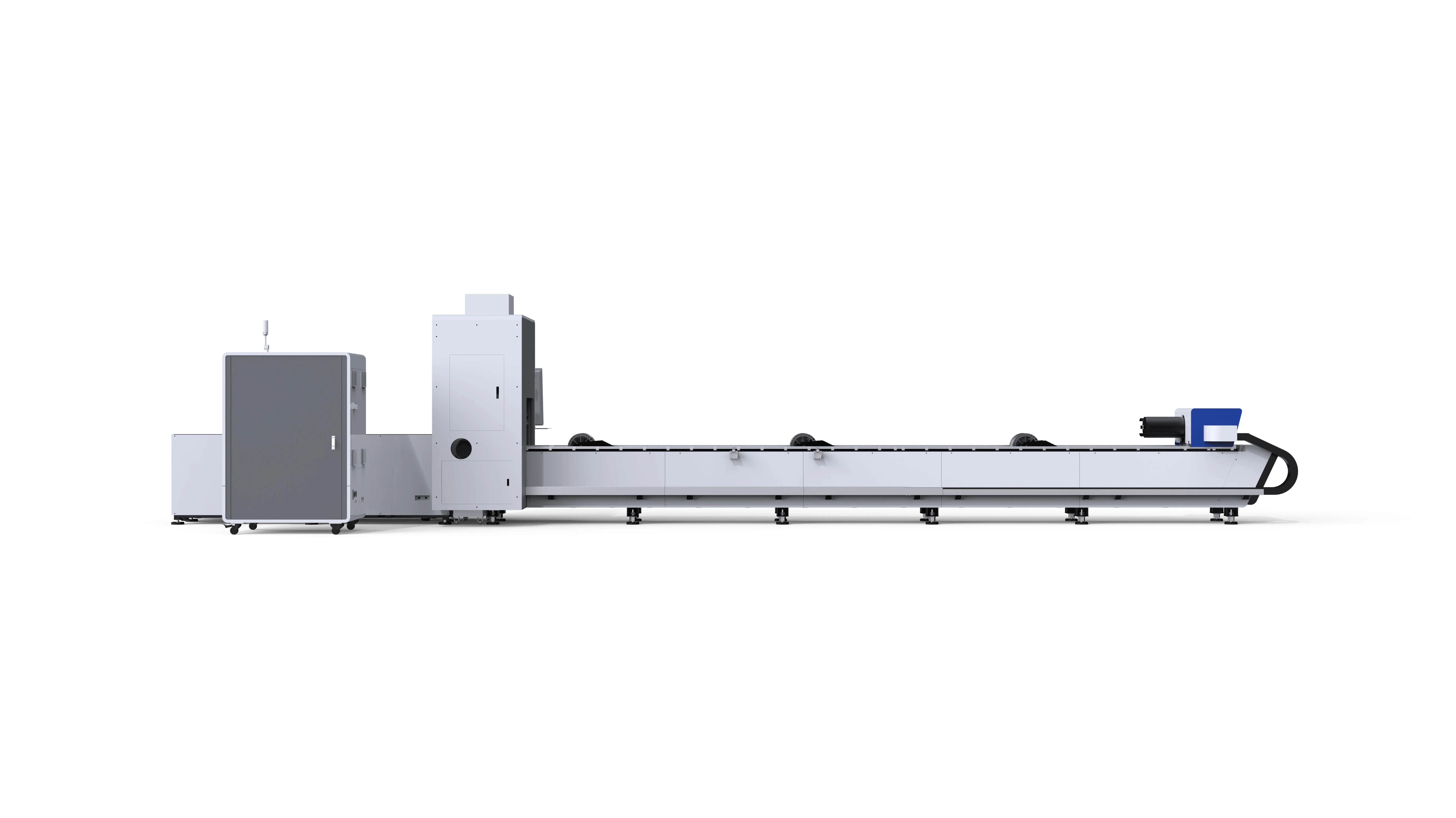

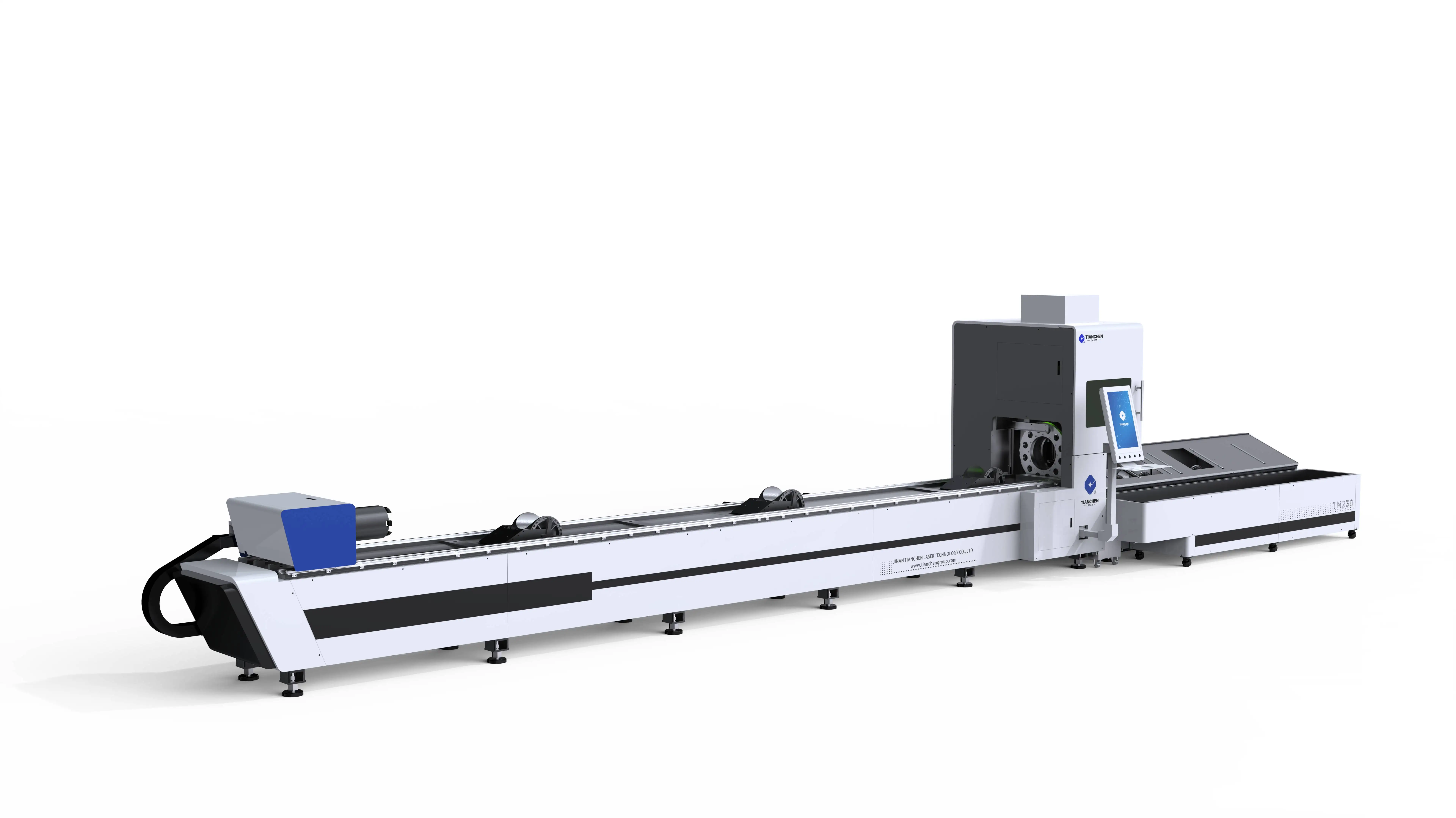

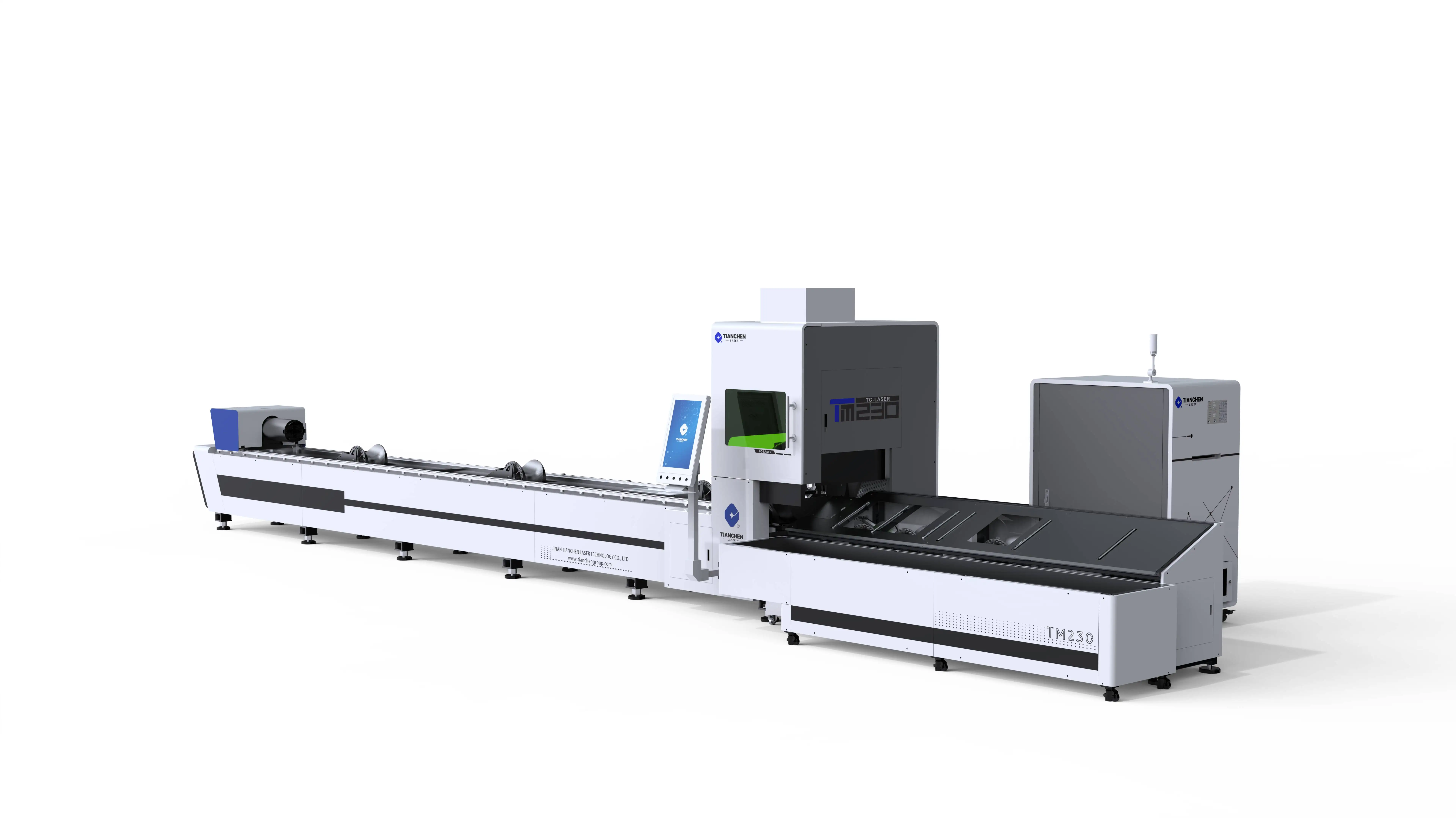

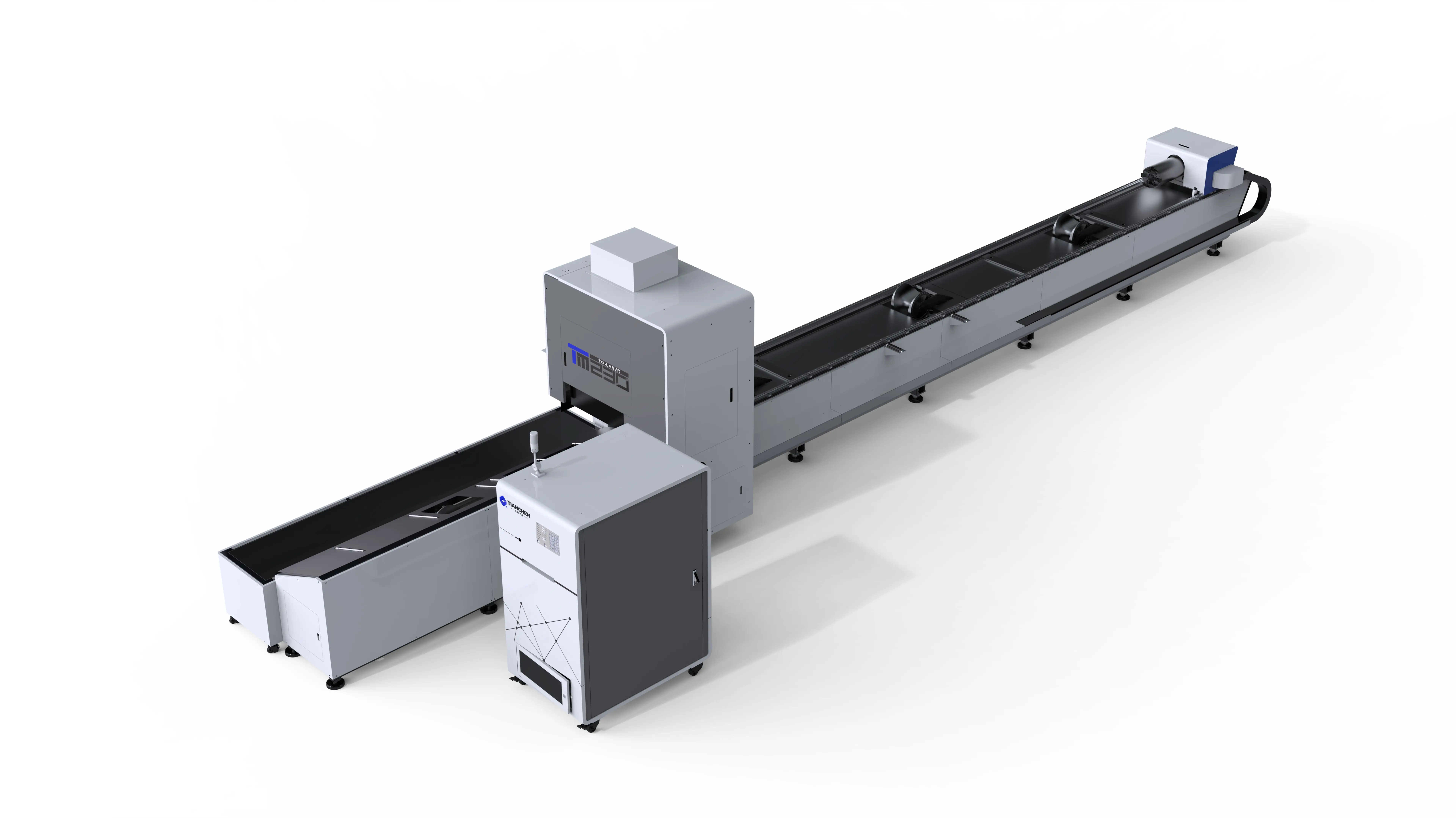

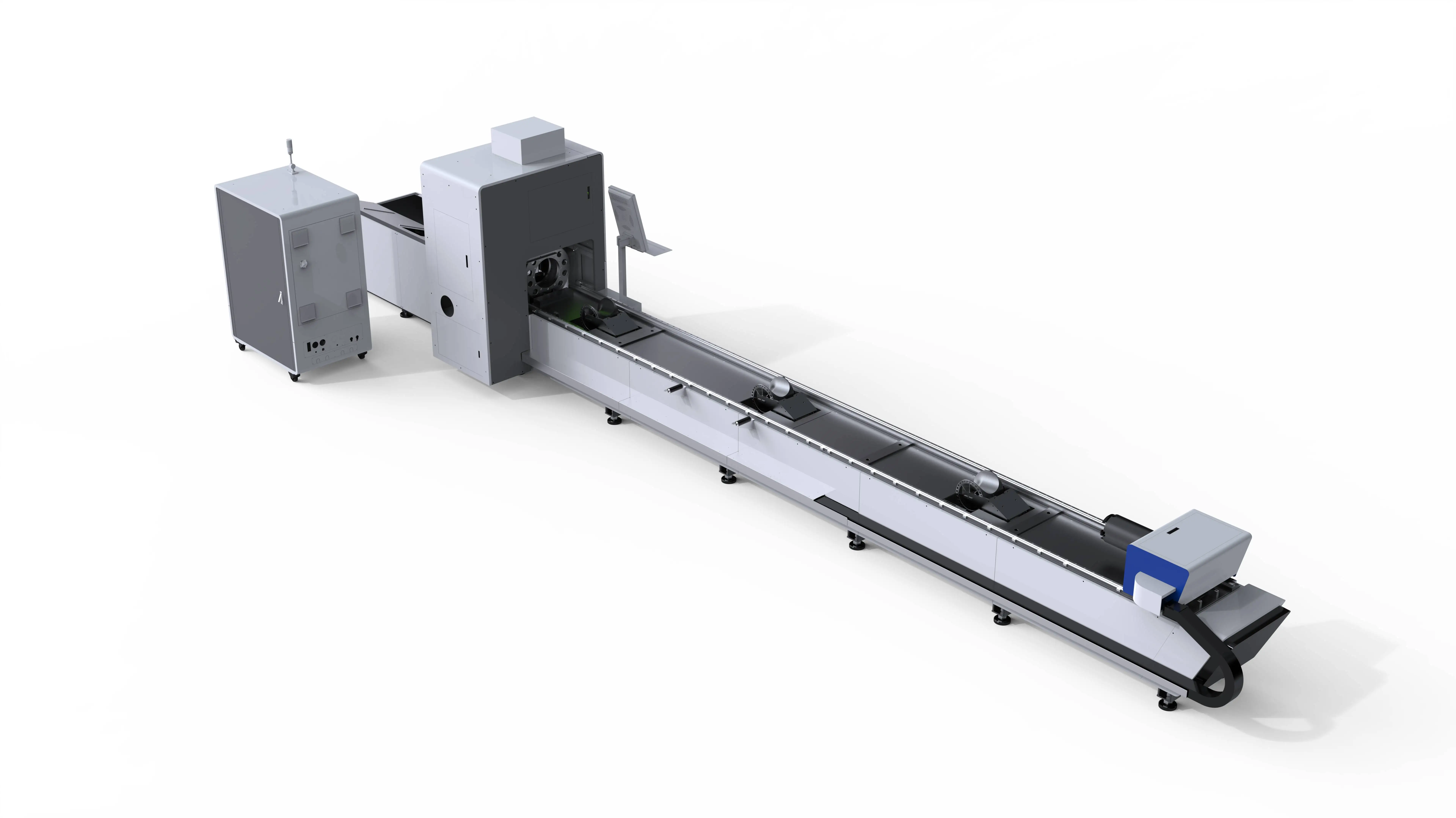

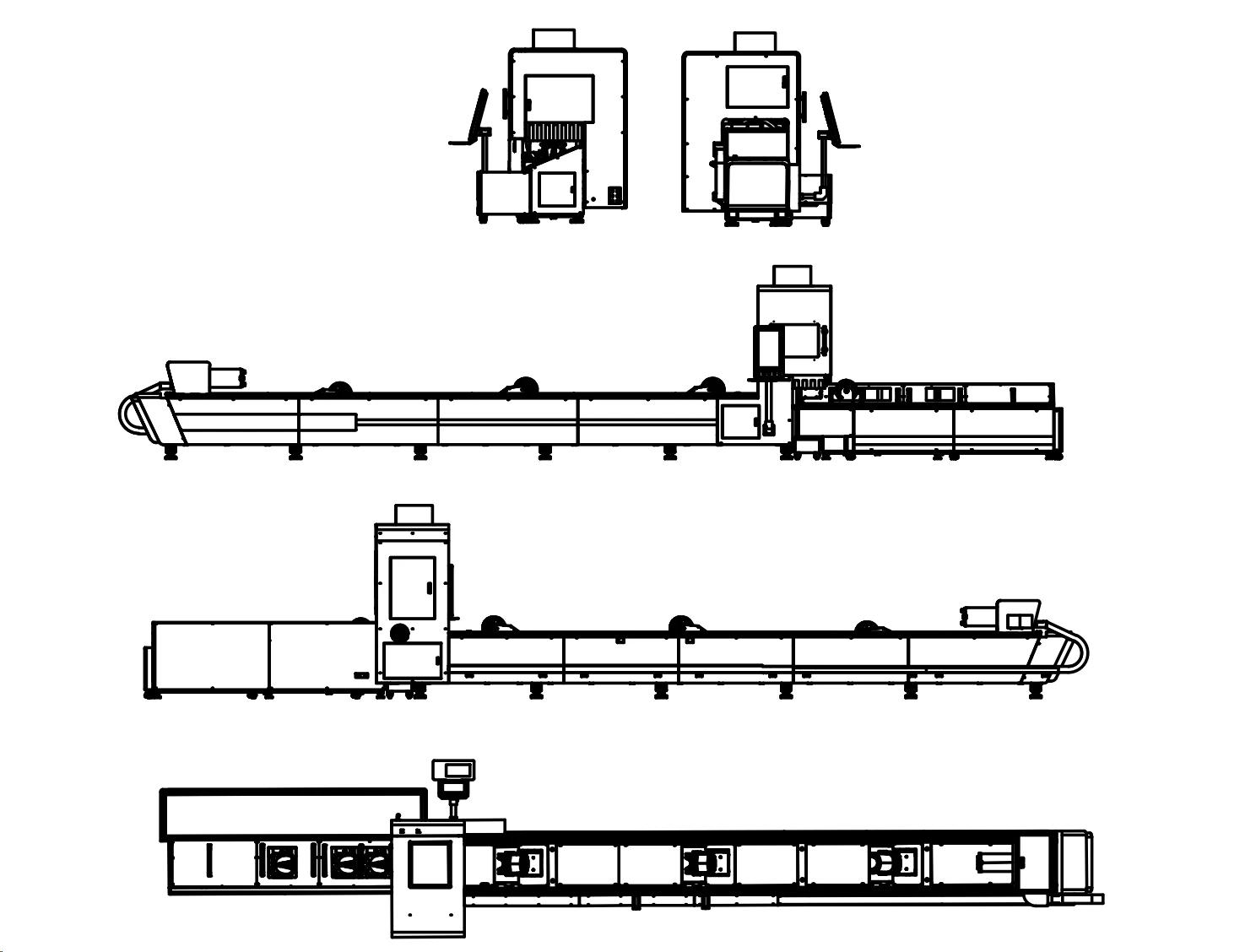

Basic parameter | Plate working area | 6m-Φ230mm | |

Positioning accuracy | 0.05mm | ||

Repositioning accuracy | 0.03mm | ||

Maximum feed speed of rear chuck | 80m/min | ||

Max. acceleration | 0.7 | ||

Size of the main unit (with 3m feeding) | 11450*2200*2100mm | ||

Total weight of machine | 4T | ||

Tube size range | Round tube:Φ15-Φ230mm Square tube:Φ15-Φ230mm Circumscribed circle diameter≤320mm | ||

Requirements for tubes | Diameter<φ40mm:Wall thickness of tubes≥1mm; Diameter≥φ40mm: ≥1/40 Wall thickness≥2.5% of Diameters of tubes | ||

Clamping angle steel and channel steel jaws | Exceeding the standard jaw clamping range requires additional non-standard jaws | ||

Min. tube material surplus | Min. tube material surplus | ||

Chuck | CANTINI | ||

Chuck drive types | Ppneumatic chuck | ||

Chuck air pressure | 0.4-0.9Mpa | ||

Chuck maximum load | 200kg 30kg/m | ||

Maximum blanking length | 25*φD 25 times the diameter | ||

Maximum speed of chuck | 105RPM/MIN | ||

Chuck rotation accuracy | ≤0.1mm | ||

Chuck repeat positioning accuracy | ≤0.1mm | ||

Support power | 1-6KW | ||

Mechanical system | Machine bed | Tube welding bed | |

Gantry structure | Plate welded beams | ||

Servo motor and driver | INOVANCE/YASKAWA | ||

Slideway | taly PEK/Taiwan HIWIN | ||

Rack | Italy PEK/Taiwan YYC | ||

Reducer | France MOTOREDUCER | ||

Gear | France MOTOREDUCER | ||

Peripheral system | Laser source | MAX/Raycus/IPG | |

Laser head | BoCi/RayTools | ||

Water cooler | HANLI/TongFei/S&A | ||

Intelligent control system | Control system | FSCUT3000S | |

Control mode | Pulse control | ||

TubesT tube nesting software (Tube cutting part) | 1. This nesting software must be provided when cutting channel steel and angle steel; 2. Use this nesting software when cutting complex graphics and typesetting of ordinary pipes such as round pipes and square pipes to improve utilization rate | ||

O2 Cutting gas control valve | Japan SMC/Airtac |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan