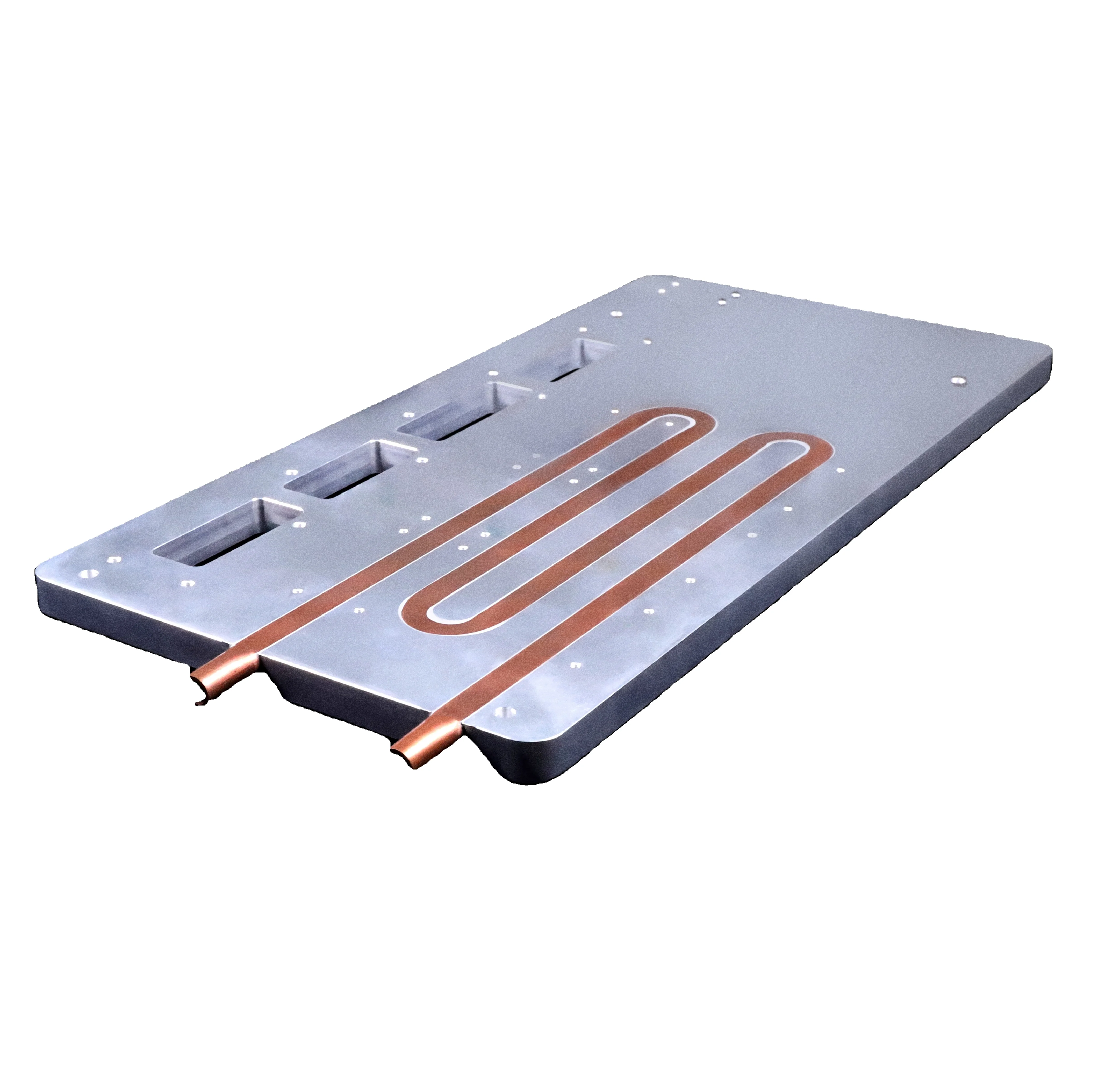

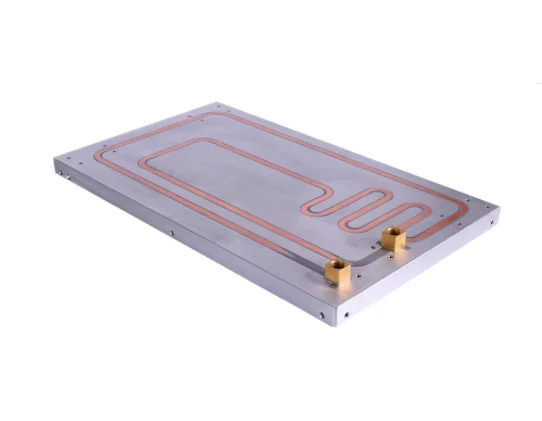

The Liquid Cold Plate is a compact, advanced cooling solution for high-performance electronics. Its direct contact with coolant

ensures efficient heat transfer, eliminating the need for intermediate interfaces. Customized to fit various sizes, it enhances system reliability and performance. Compared to air cooling, liquid cooling offers superior heat dissipation, reducing operating

temperatures, prolonging component lifespans, and boosting overall system efficiency.

[CODE_4]: MEDIA_ELEMENT_ERROR: Format error