[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

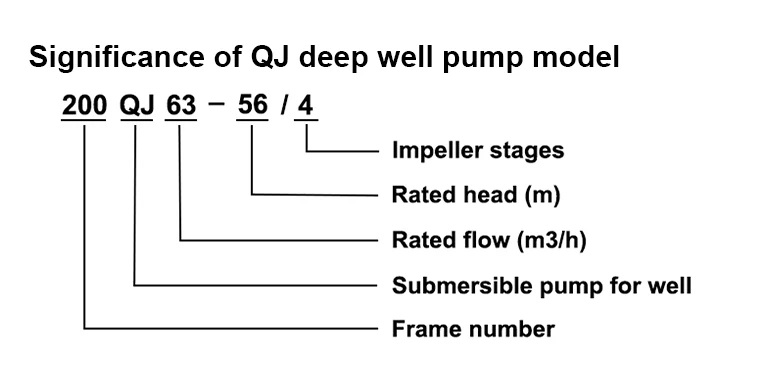

Diameter | Model | Kekuatan | Rentang arus | Head range | ||

Inci (") | Tipe QJ | Kw | Hp | M3/h | M | |

6" | 150QJ40-66 | 13 | 18 | 32-48 | 63-69 | |

7" | //6 | 7.5 | 10 | 13-17 | 77-83 | |

7" | //8 | 11 | 15 | 18-22 | 100-108 | |

7" | //10 | 15 | 20 | 23-27 | 125-135 | |

7" | //7 | 13 | 18 | 29-35 | 81-87 | |

7" | //10 | 22 | 30 | 37-43 | 115-125 | |

8" | //6 | 7.5 | 10 | 13-17 | 68-92 | |

8" | //11 | 15 | 20 | 18-22 | 126-170 | |

8" | //13 | 18.5 | 25 | 18-22 | 150-210 | |

8" | //15 | 22 | 30 | 18-22 | 172-232 | |

8" | //18 | 25 | 35 | 18-22 | 206-280 | |

8" | //21 | 30 | 40 | 18-22 | 240-325 | |

8" | //25 | 37 | 50 | 18-22 | 287-388 | |

8" | //30 | 45 | 60 | 18-22 | 345-465 | |

8" | //4 | 7.5 | 10 | 23-27 | 45-67 | |

8" | //5 | 9.2 | 13 | 23-27 | 56-84 | |

8" | //7 | 11 | 15 | 23-27 | 84-112 | |

8" | //9 | 15 | 20 | 23-27 | 100-145 | |

8" | //11 | 18.5 | 25 | 23-27 | 138-184 | |

8" | //13 | 22 | 30 | 23-27 | 150-210 | |

8" | //16 | 30 | 40 | 23-27 | 190-258 | |

8" | //21 | 37 | 50 | 23-27 | 250-340 | |

8" | //8 | 22 | 30 | 29-35 | 106-150 | |

8" | 200 qj50-65/5 | 15 | 25 | 46-54 | 52-78 | |

8" | //9 | 37 | 50 | 58-68 | 100-147 | |

8" | //6 | 45 | 60 | 80-120 | 88-92 | |

10" | 250 qj50-140/7 | 30 | 40 | 46-54 | 119-161 | |

10" | 250QJ50-340/17 | 75 | 100 | 46-54 | 315-375 | |

10" | //11 | 90 | 120 | 74-86 | 190-250 | |

10" | //12 | 100 | 135 | 80-120 | 190-252 | |

10" | //12 | 110 | 150 | 113-134 | 163-220 | |

10" | //12 | 125 | 170 | 130-145 | 156-205 | |

12" | //2 | 37 | 50 | 186-214 | 35-45 | |

12" | //4 | 110 | 150 | 279-321 | 68-92 | |

12" | //3 | 220 | 300 | 368-432 | 117-123 | |

12" | //4 | 140 | 190 | 460-540 | 57-63 | |

14" | //1 | 30 | 40 | 233-267 | 22-28 | |

14" | //4 | 185 | 250 | 305-335 | 115-125 | |

16" | //1 | 90 | 120 | 460-540 | 38-42 | |

16" | //1 | 45 | 60 | 460-540 | 18-22 | |

18" | //1 | 90 | 120 | 900-1200 | 12-20 | |

20" | //3 | 260 | 350 | 600-680 | 82-86 | |

22" | //1 | 110 | 150 | 1100-1400 | 15-22 | |

24" | //2 | 220 | 300 | 750-850 | 48-52 | |

24" | //3 | 300 | 400 | 900-1200 | 58-62 | |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.