[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Specification | ||||||||

Items | Specification | |||||||

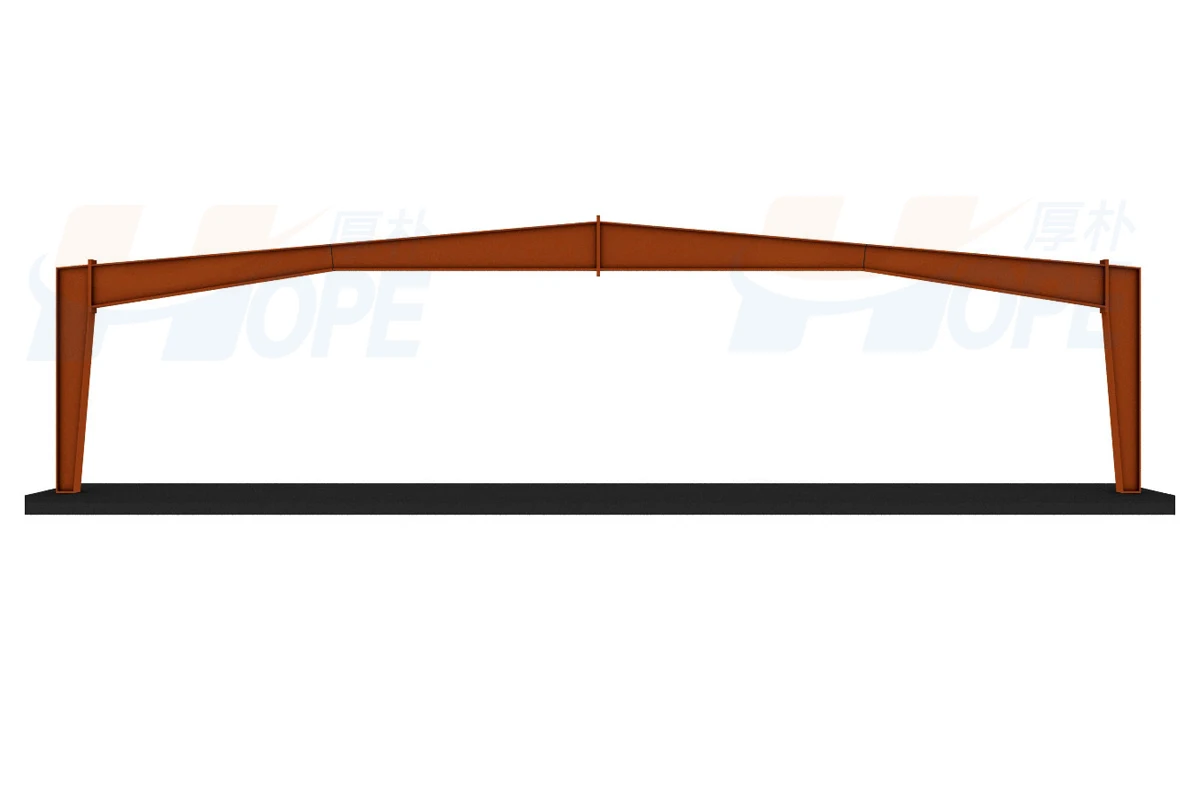

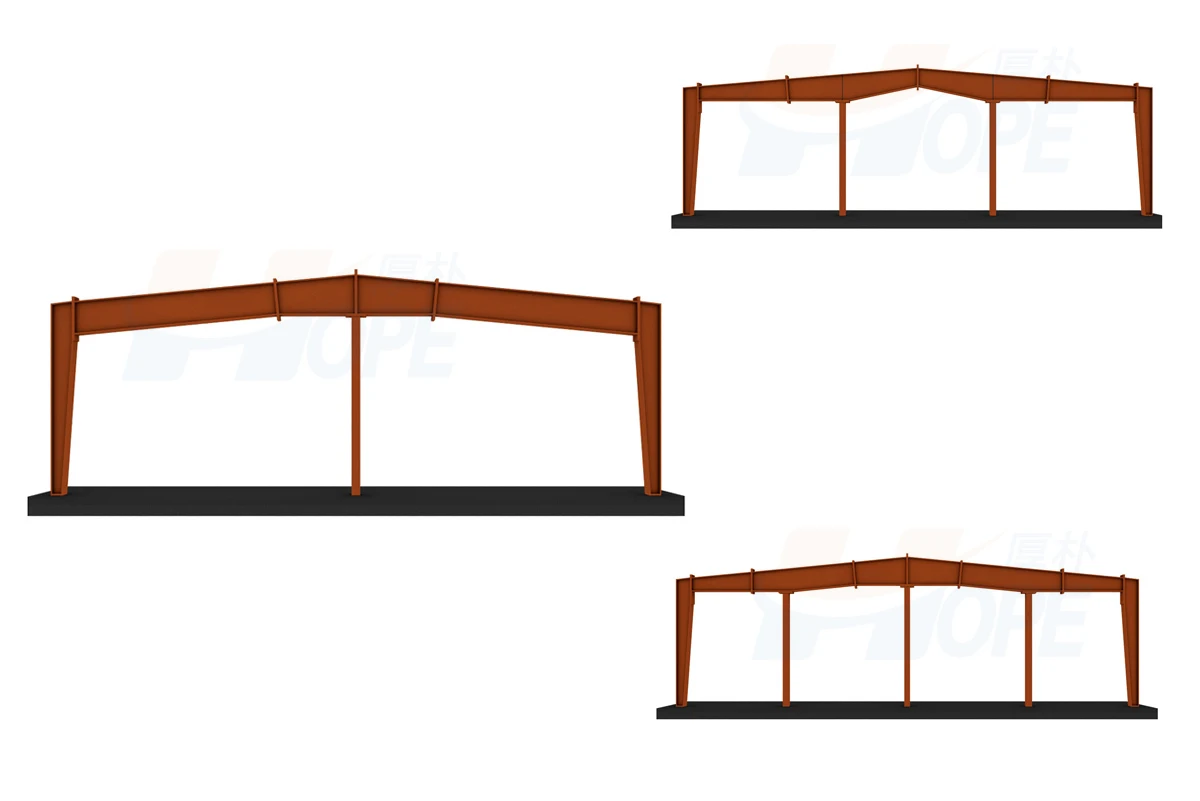

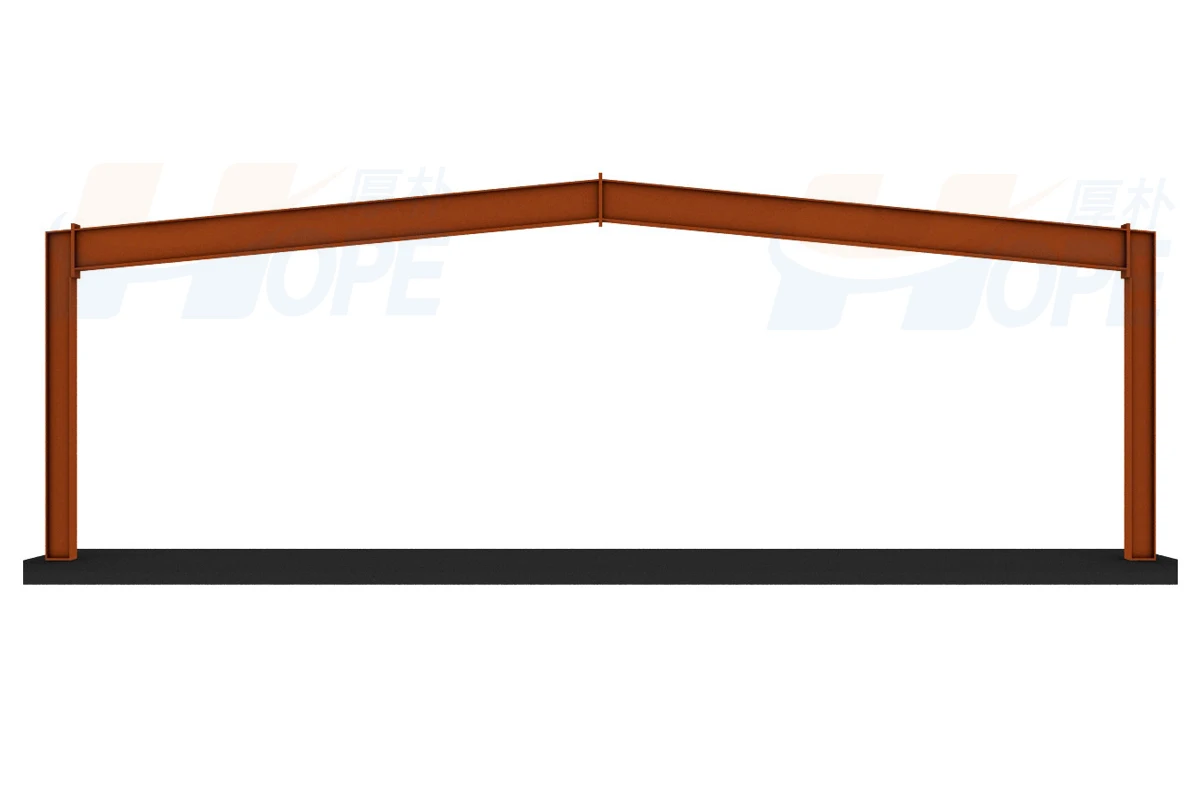

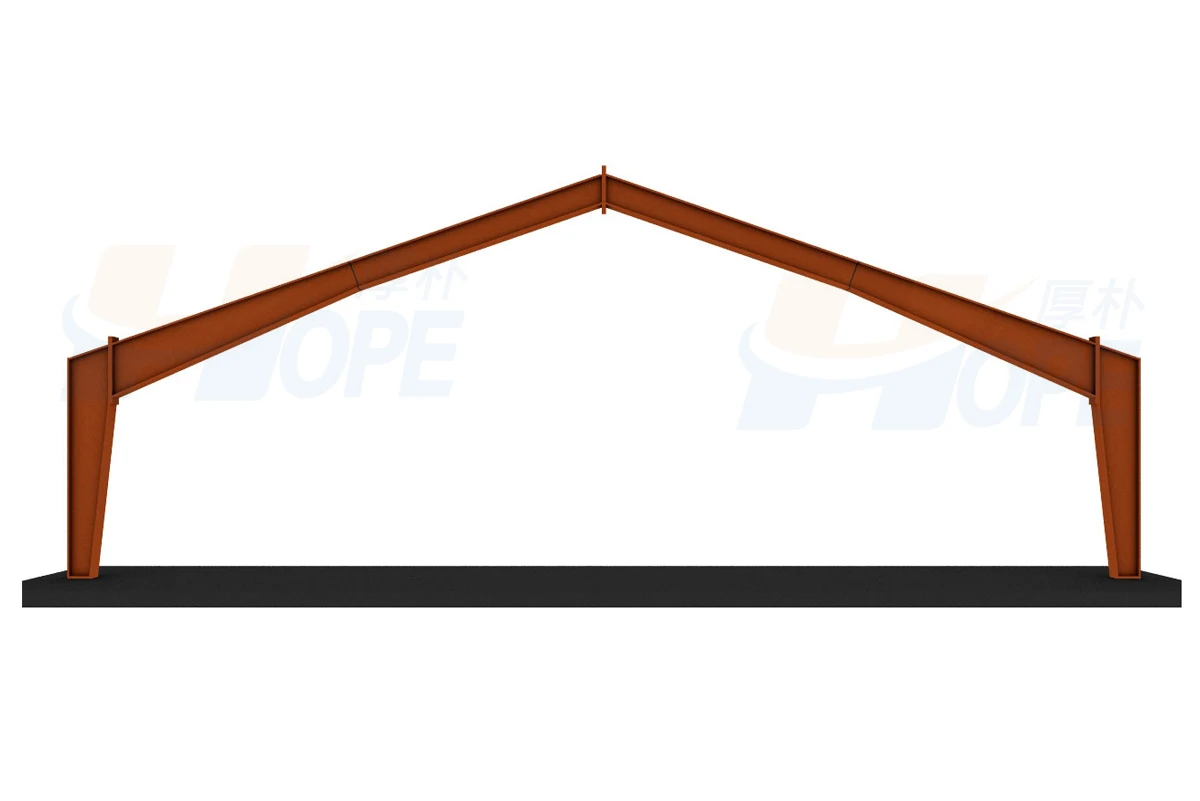

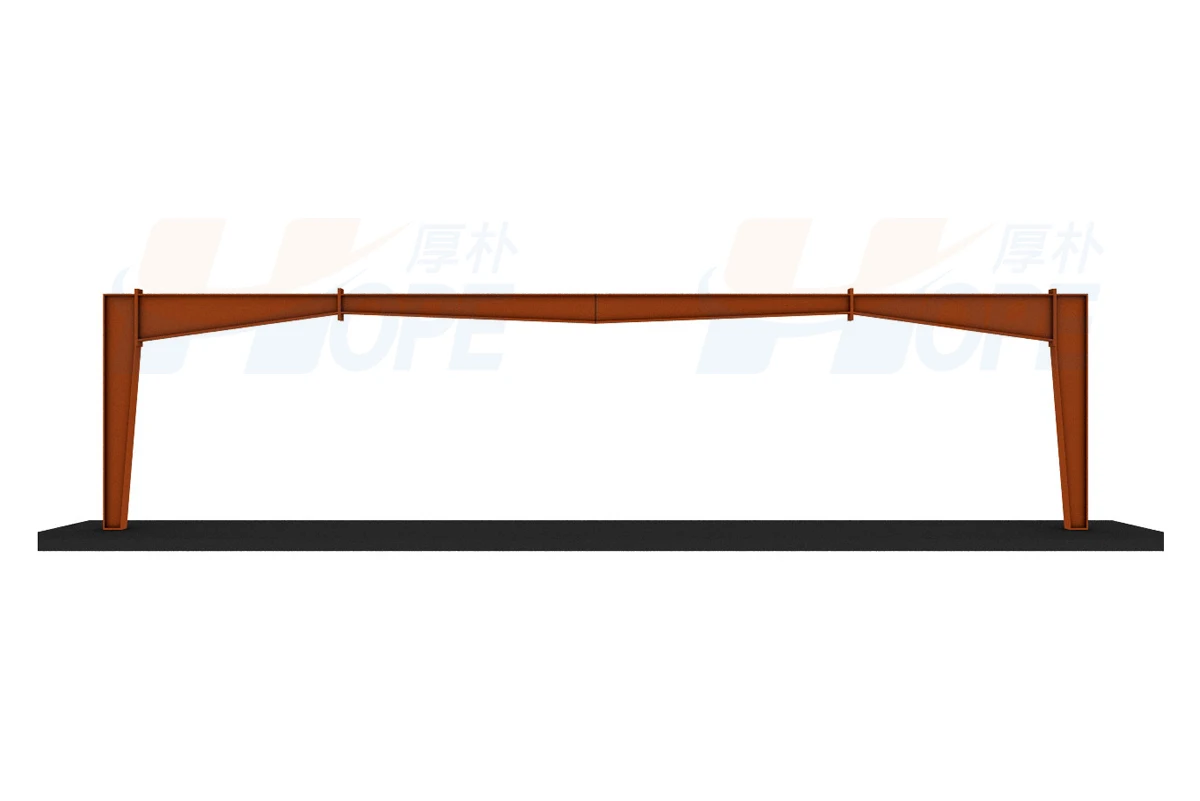

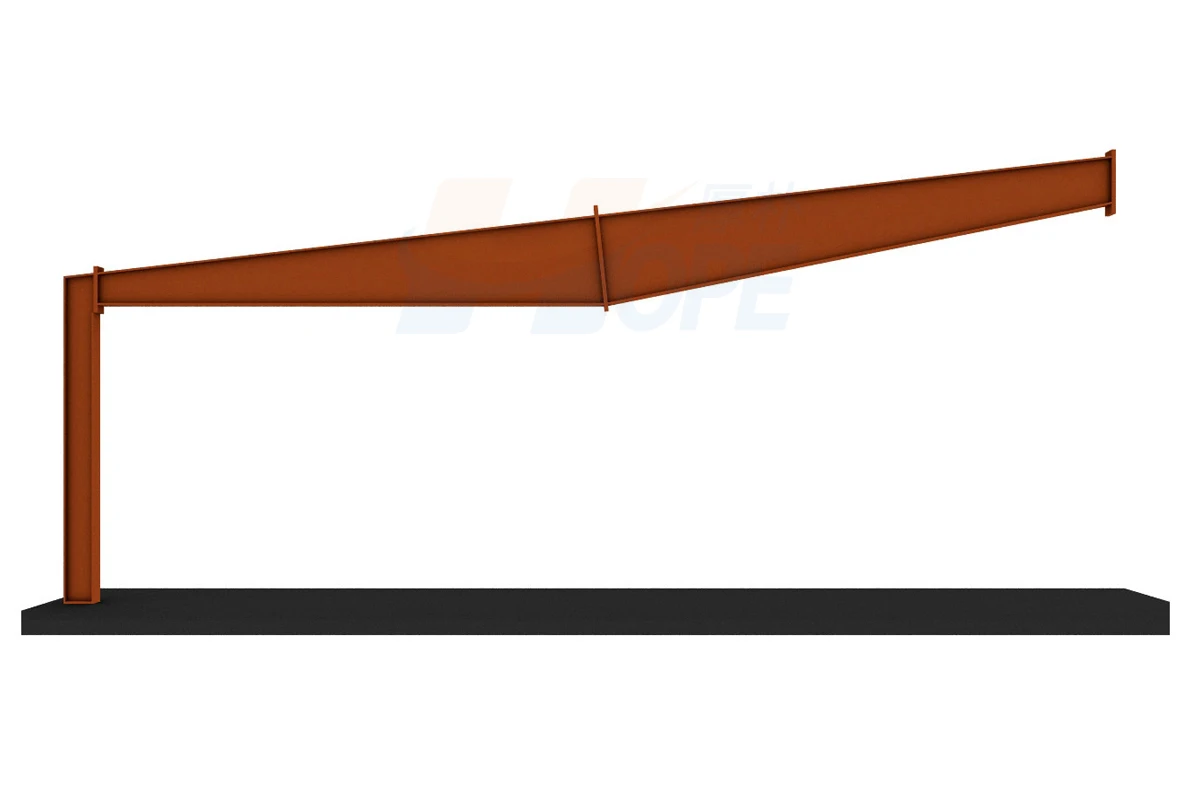

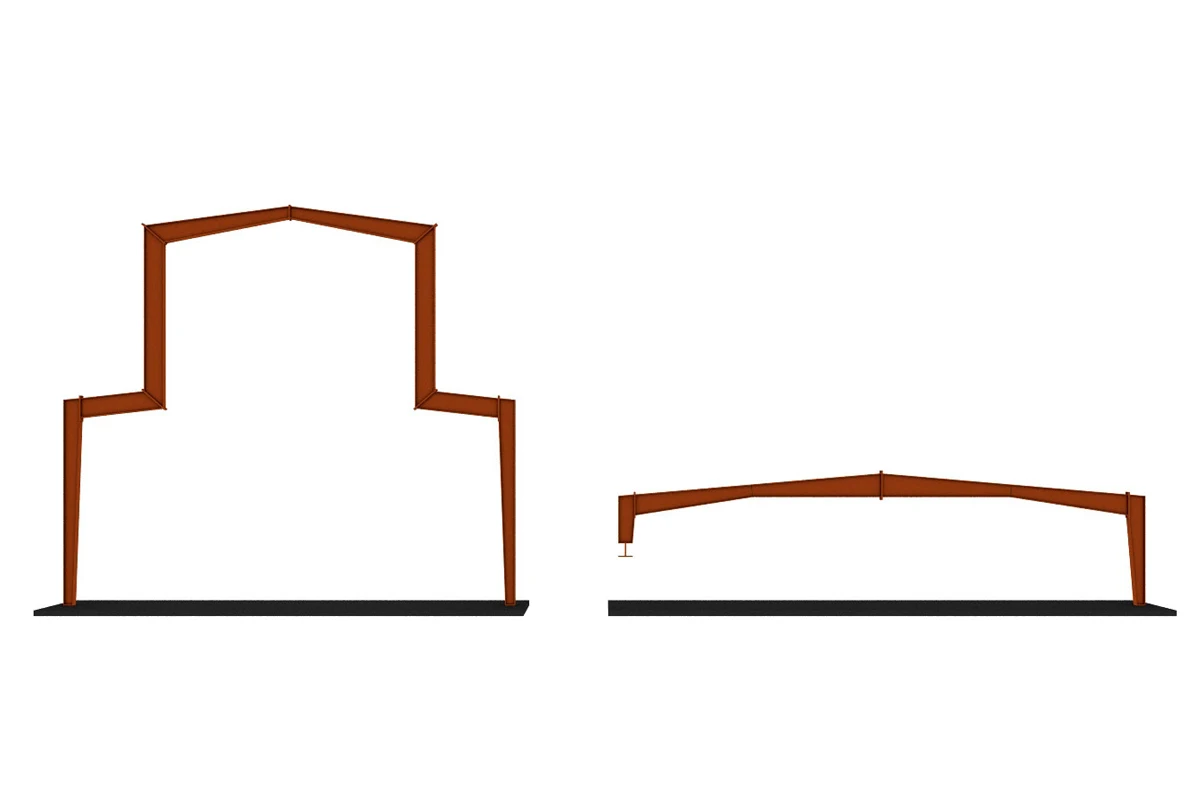

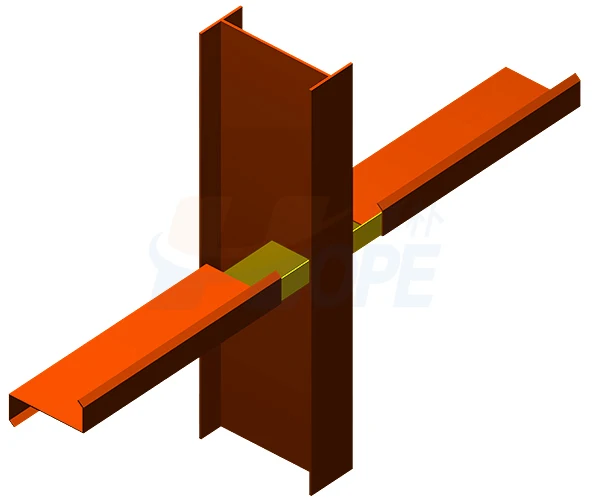

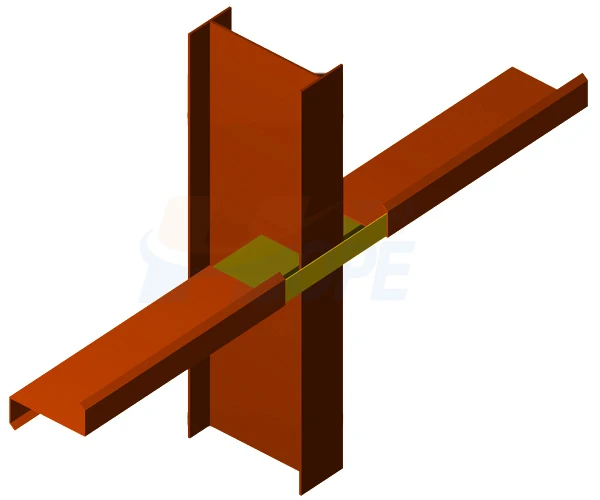

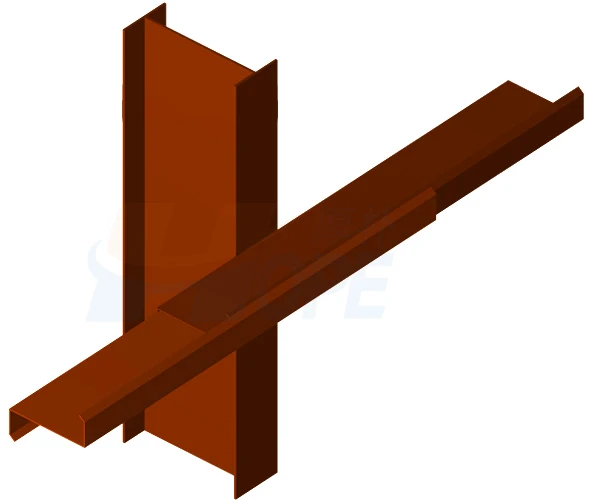

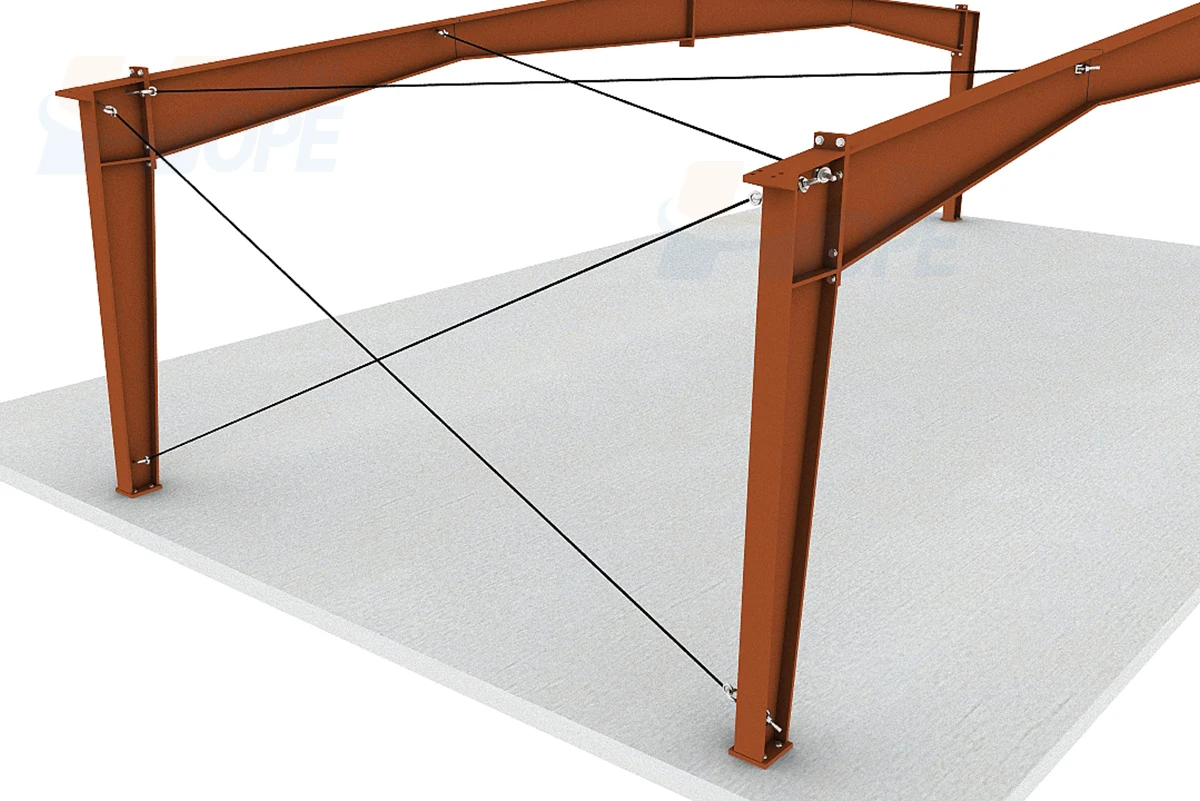

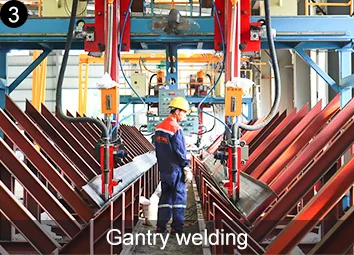

Main Steel Frame | Column | Q235, Q355 Welded H Section Steel | ||||||

Beam | Q235, Q355 Welded H Section Steel | |||||||

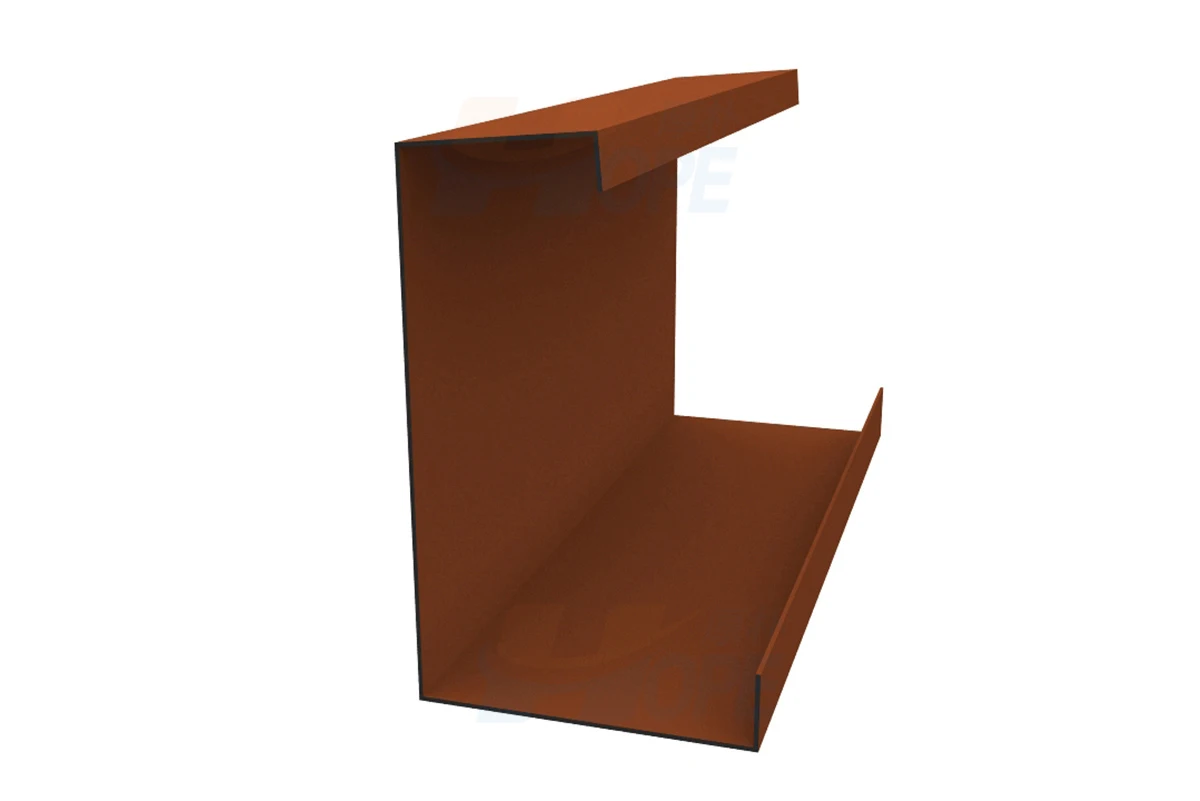

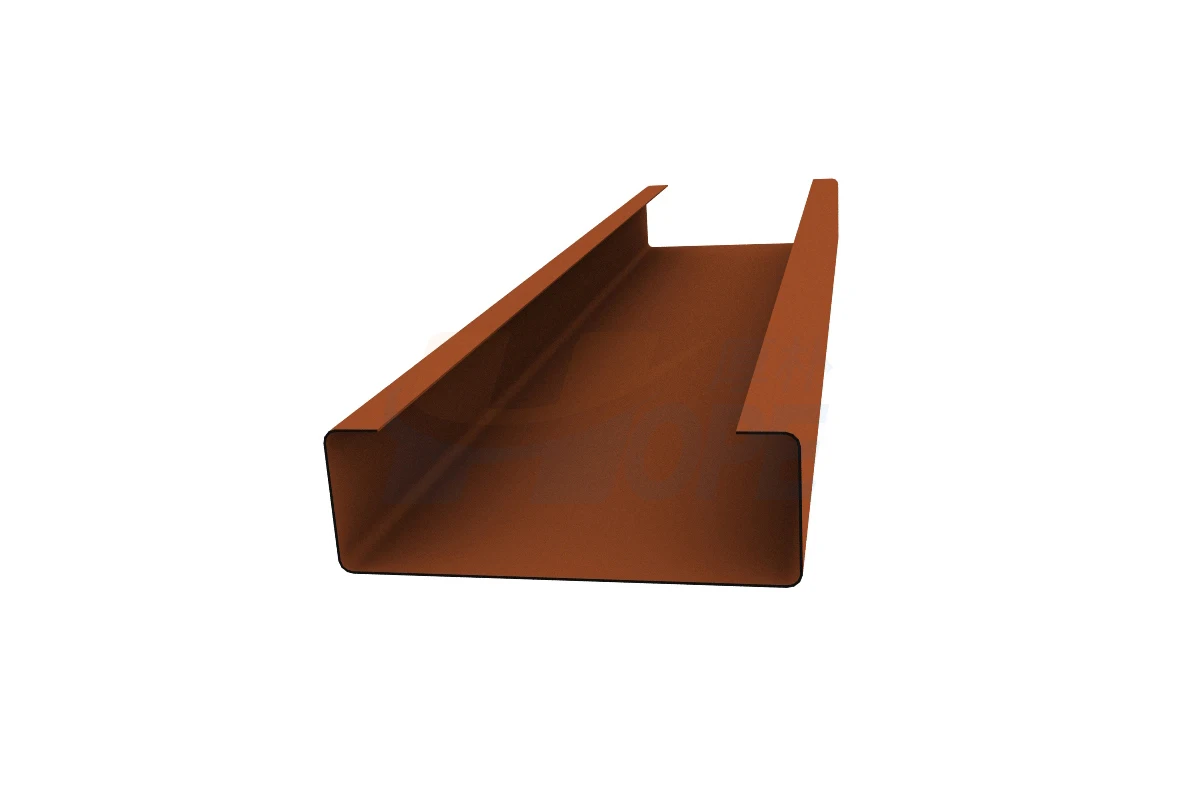

Secondary Frame | Purlin | Q235 C and Z purlin | ||||||

Knee brace | Q235 Angle Steel | |||||||

Tie Rod | Q235 Circular Steel Pipe | |||||||

Brace | Q235 Round Bar | |||||||

Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |||||||

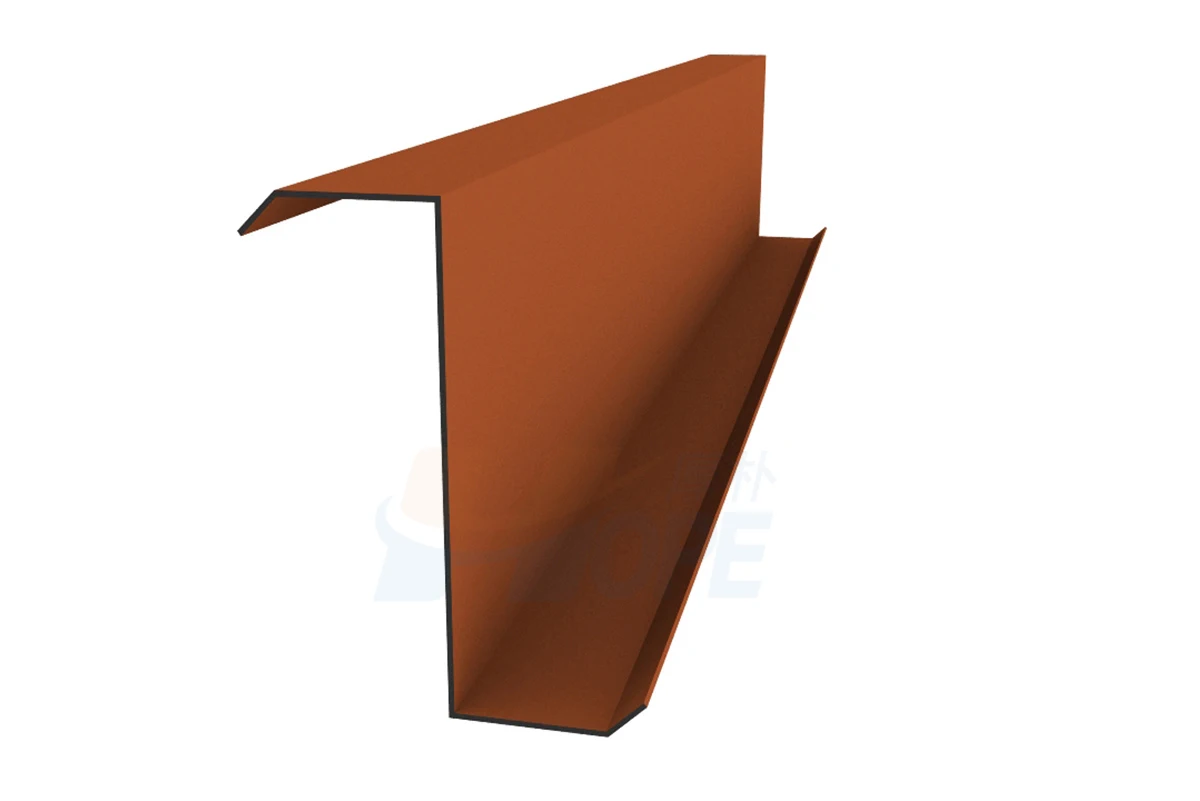

Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet | ||||||

Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |||||||

Accessories | Window | Aluminiumn Alloy Window / PVC Window / Sandwich Panel Window | ||||||

Door | Sliding Sandwich Panel Door / Rolling Metal Door | |||||||

Rainspout | PVC | |||||||

Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) | |||||||

Wind Resistance Grade | 12 Grades | |||||||

Earthquake-resistance | 8 Grades | |||||||

Structure Usage | Up to 50 years | |||||||

Finishing Options | Vast array of colors and textures available | |||||||

Paint Options | Alkyd paiting, two primary painting, two finish painting (Primer 、Medium paint 、top coat, epoxy zinc etc.) Or Galvanized. | |||||||

Pesanan tiba sebelum jadwal, atau dapatkan kompensasi 10% dari harga pesanan jika pengiriman telat.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.