With leading R&D technology,experienced manufacturing,good quality control and global supply capabilities,we have established good cooperation with a number of auto parts manufacturers both domestically and internationally.

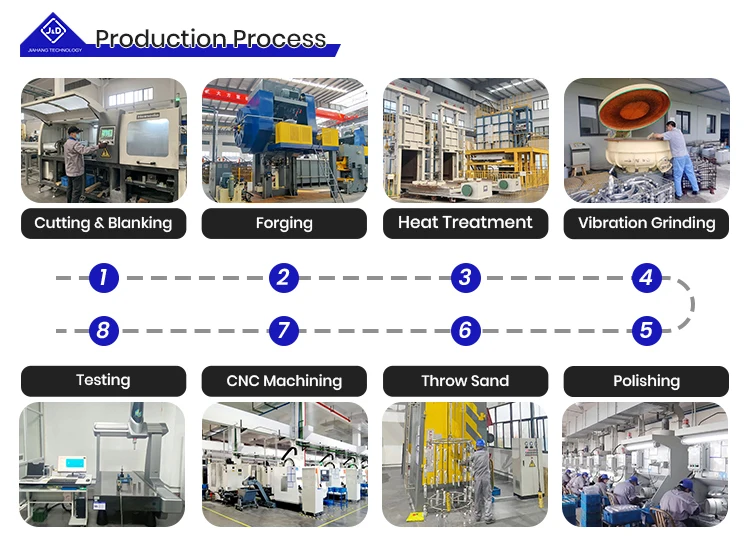

Our forging equipments are first-class hot die forging, reaching maximum forging size of 1000mm. With 16 lines in total,the tonnage of each forging equipment spans 240T, 300T, 630T, 800T, 1000T, 1600T, 2500T and 4000T which covers 90% of the forging tonnage requirements on the market. And the annual production volume exceeds 6,500,000 pieces.

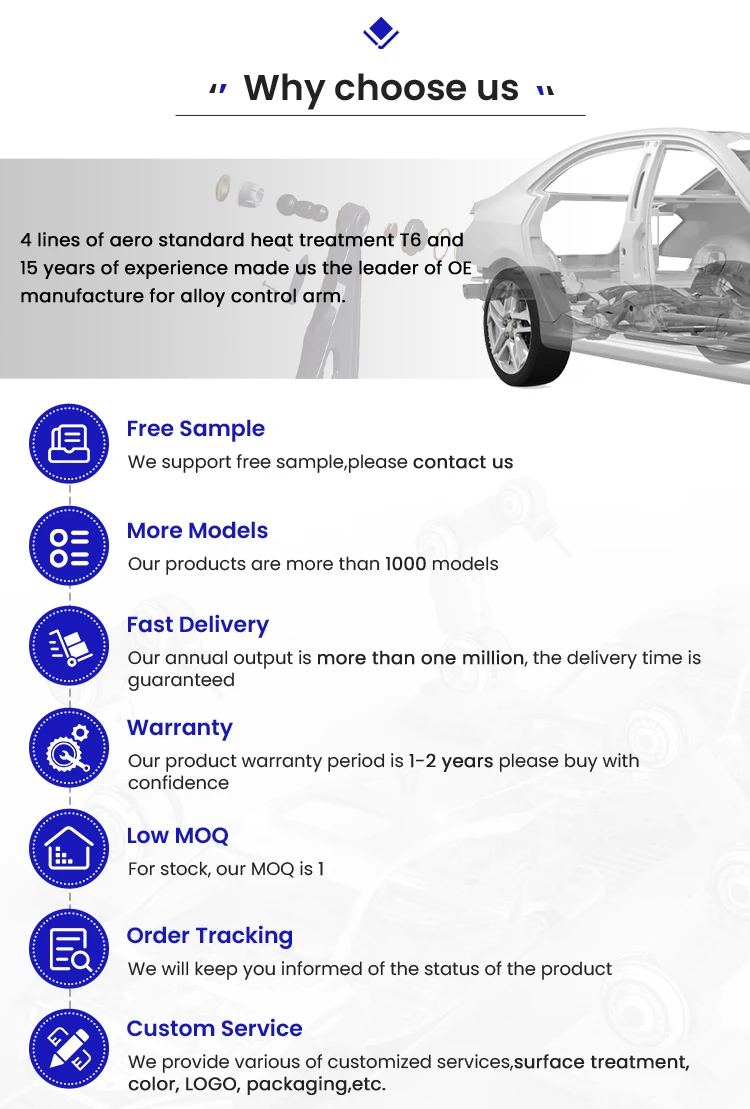

4 lines of aero standard heat treatment T6 and 30 years of experience made us the leader of control arm manufacturer. More than 100 CNC machines ensure an annual output of more than 5,000,000 pieces. high quality rubber bushing makes our products excellent in all respects. To be more rigorous we also utilize intenal physical and dimensional testing equipment to ensure the products are all in good condition.

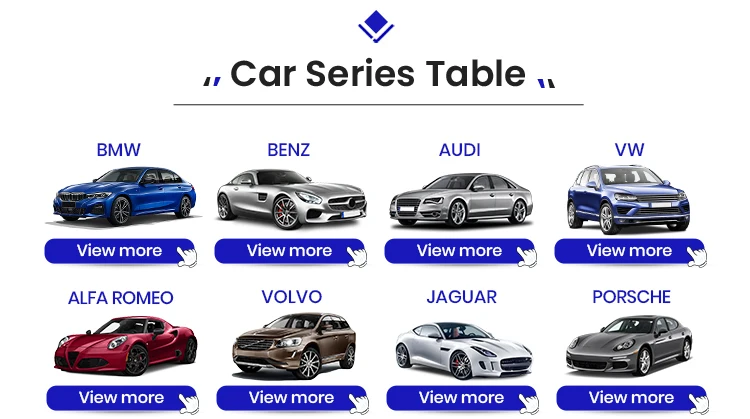

We designed and produced more than a thousand sets of forging dies strictly according to OE standard. Our company has obtained the IATF16949 & AS9100D & NADCAP & ISO9001 certification. Relying on advanced corporate management concepts,we are committed to the cause of aluminum alloy light weight of automotive suspension market.