COLLECTOR UNIT

1.The non-stop collector height can reach 1300mm. When the stack is almost full, the delivery conveyor belt will automatically extend to accept the paper. The collector platform will drop. After the tray is replaced, the platform will recycle and complete the non-stop collector.

2.Adopt pneumatic paper sorting structure to ensure the paper in the good order.

3.Avoid paper breakage due to excessive speed hitting the baffle.

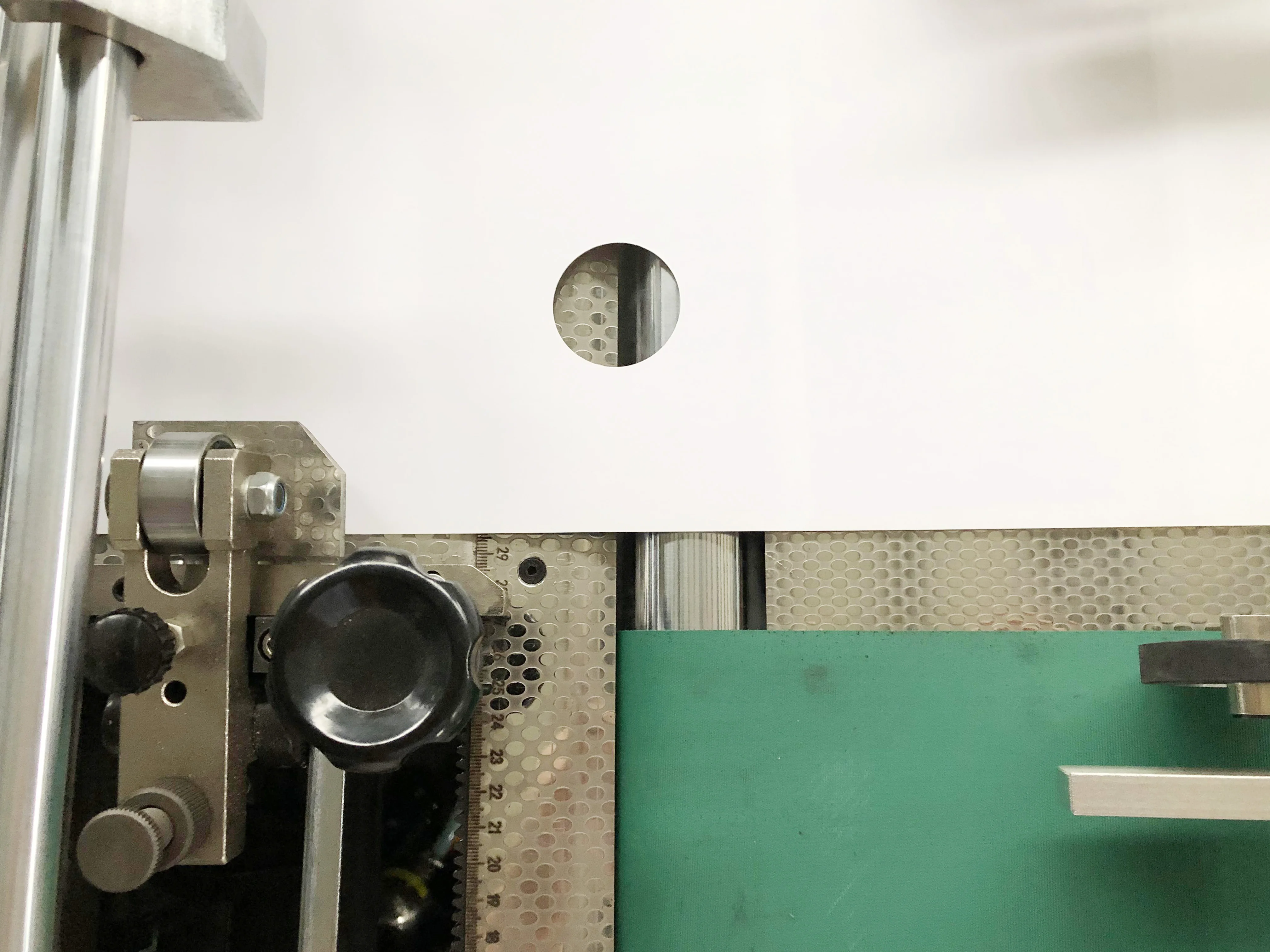

4.Counting electric eye: the number of running paper is read by the display, and the data can be cleared and totalized.

5.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the collector will overturn, paper is kicked out..