Simplistic

Flexibility

Open Design

Modular Structure

Easy Maintenance

Tool-free Concept

Layanan di tempat & suku cadang gratis

Layanan di tempat & suku cadang gratis

Model | Acrab350 | Acrab450 | ||

Dimension:(mm) | 4420X1420X1750 | 4420X1520X1750 | ||

Weight(kg) | Approx.1600kg | Approx.1900kg | ||

Power Supply | 3P5W,380/220V 50Hz | |||

Startup Power | 33kw | |||

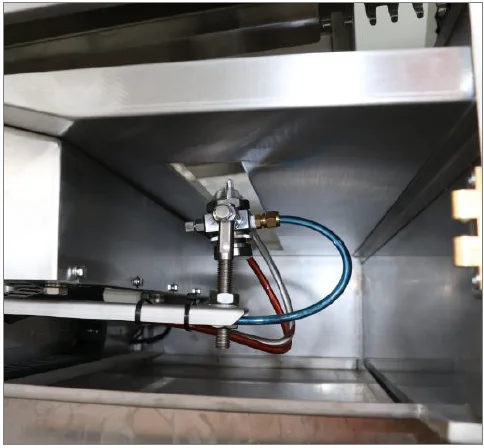

Spray System | ||||

Transmission Methed | Step motor | |||

Flux flow | 10--100ml/min | |||

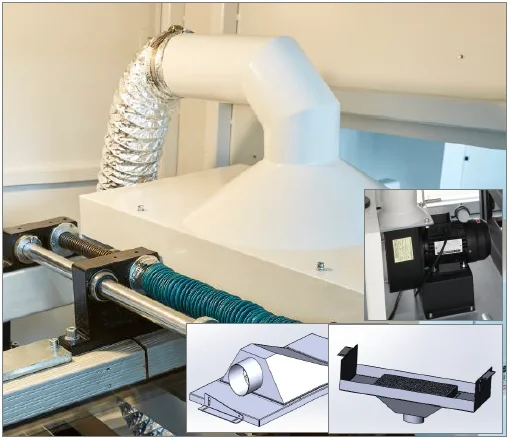

Exhaust Diameter | Φ250mm | |||

Exhaust Capacity | 25m3/min | |||

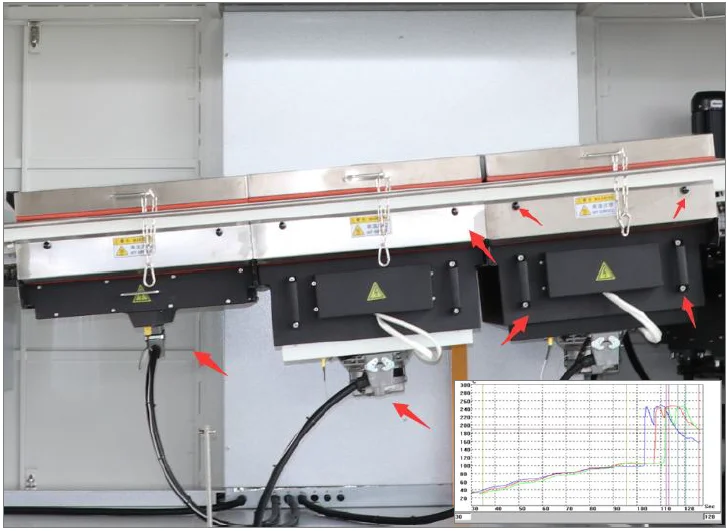

Preheating System | ||||

Preheating Mode | Hot air/IR | |||

Preheating Zone | 3 | |||

Preheating Length | 1800mm | |||

Warm-up Time(min) | Approx.15min (setting 150℃) | |||

Conveyor System | ||||

PCB Width(mm) | 50-350mm | 50-450mm | ||

Conveyor Speed | 0-2000(mm/min) | |||

Conveyor Height | 750+/-20 (mm) | |||

Available PCB Height | Top120mm(Option:250mm),Bottom15mm | |||

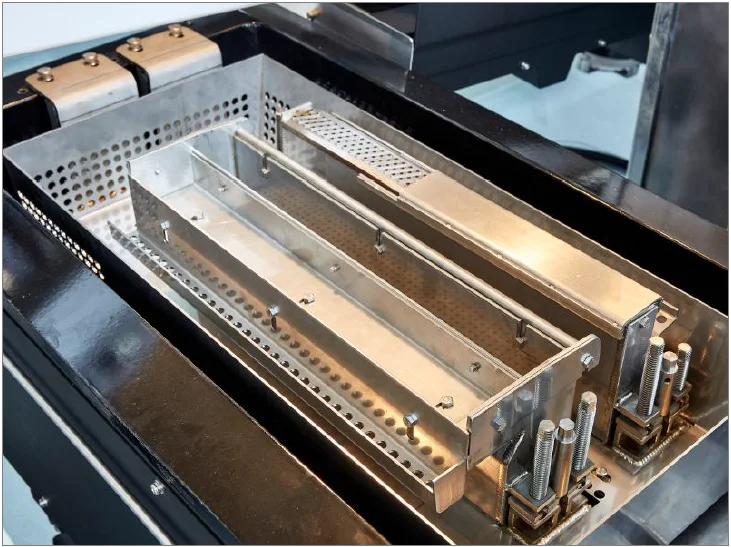

Soldering System | ||||

Solder Pot style | Mechanical Motor drive | |||

Solder Pot Capacity | Lead-free 500kg | |||

Cooling System | ||||

Cooling Method | Forced air | |||

Option: | External flux sprayer,Nitrogen protection, Selective flux spray,Chiller,MES system | |||

Q: What we can do for you? A: One-stop SMT Solution Supplier; Reliable SMT Partner |

Q: Are you a trade company or manufacturer? A: Full SMT machines maufacturer for smt line in China; OEM & ODM service are available. |

Q: What is your delivery date? A: About 35 days after receipt of payment. |

Q: What is your payment terms? A: 30% deposit in advance and 70% balance before shipment. |

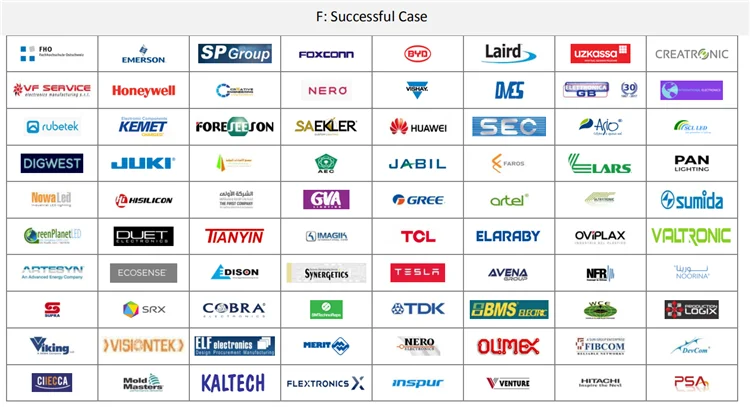

Q: What your main customers? A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc. |

Q: Why choose you? A: Leading SMT Supplier in China; Professional Supplier on Cooig; Trade assurance to USD 560,000+; Professional after-sales service team. |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.