Suku cadang gratis

Suku cadang gratis

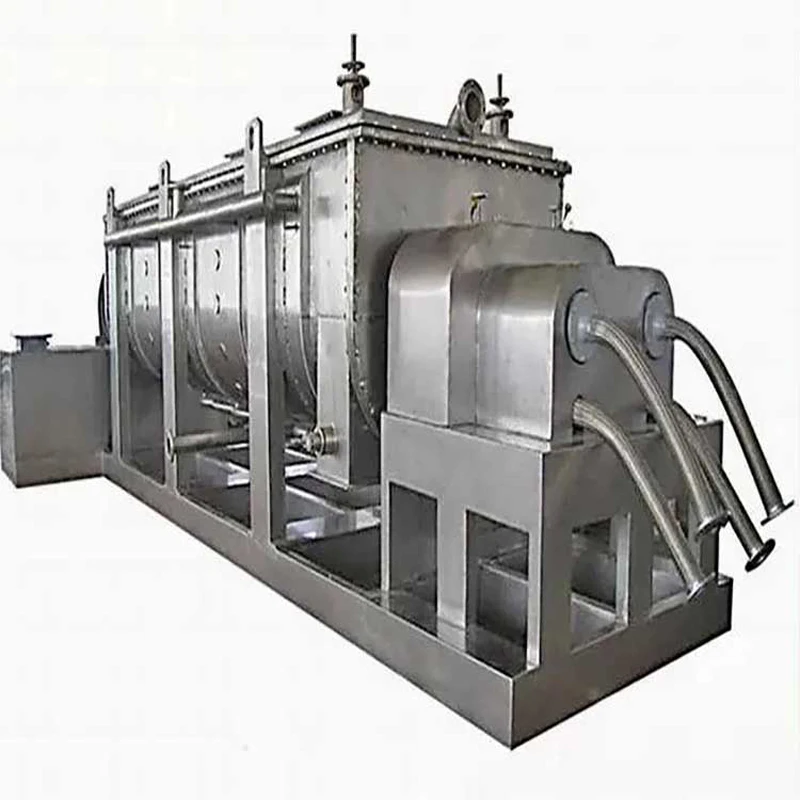

Barrel diameter(mm) | Main machine dimensions(mm) | Main machine power(kw) | Treatment wind capacity(m³/h) | Water evaporation quantity(kg/h) |

200 | 250×2800 | 5-9 | 300-800 | 10-20 |

300 | 400×3300 | 8-15 | 600-1500 | 20-50 |

400 | 500×3500 | 10-17.5 | 1250-2500 | 25-70 |

500 | 600×4000 | 12-24 | 1500-4000 | 30-100 |

600 | 700×4200 | 20-29 | 2500-5000 | 40-200 |

800 | 900×4600 | 24-35 | 3000-8000 | 60-600 |

1000 | 1100×5000 | 40-62 | 5000-12500 | 100-1000 |

1200 | 1300×5200 | 50-89 | 10000-20000 | 150-1300 |

1400 | 1500×5400 | 60-105 | 14000-27000 | 200-1600 |

1600 | 1700×6000 | 70-135 | 18700-36000 | 250-2000 |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan