1.what industries does your company specialize in?

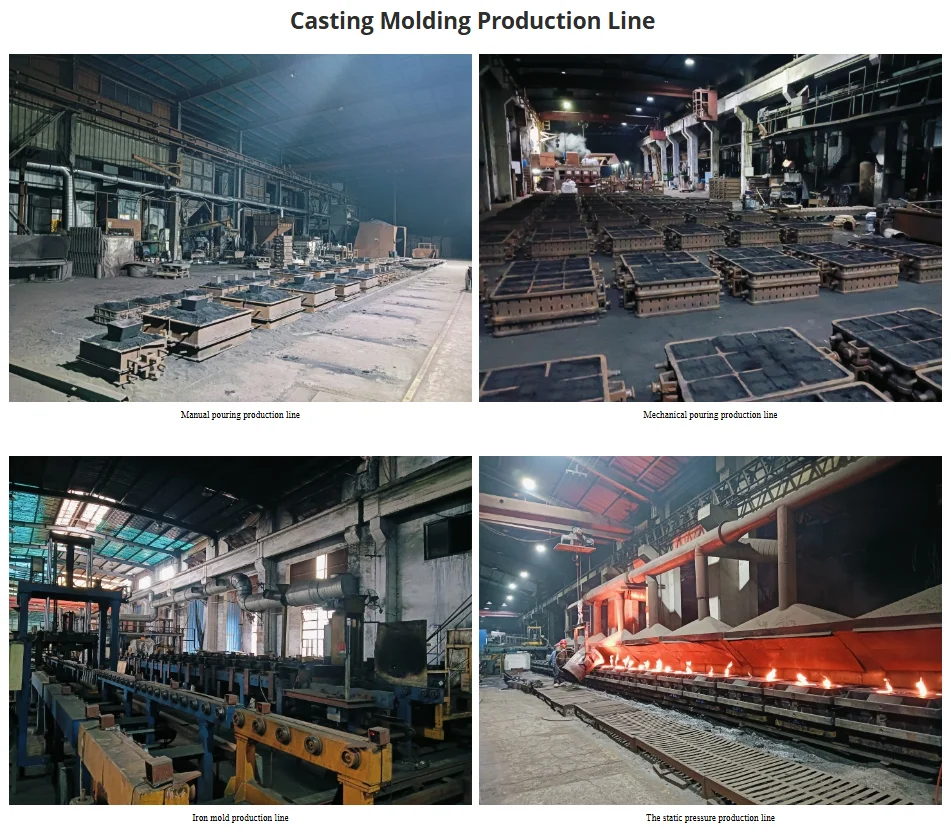

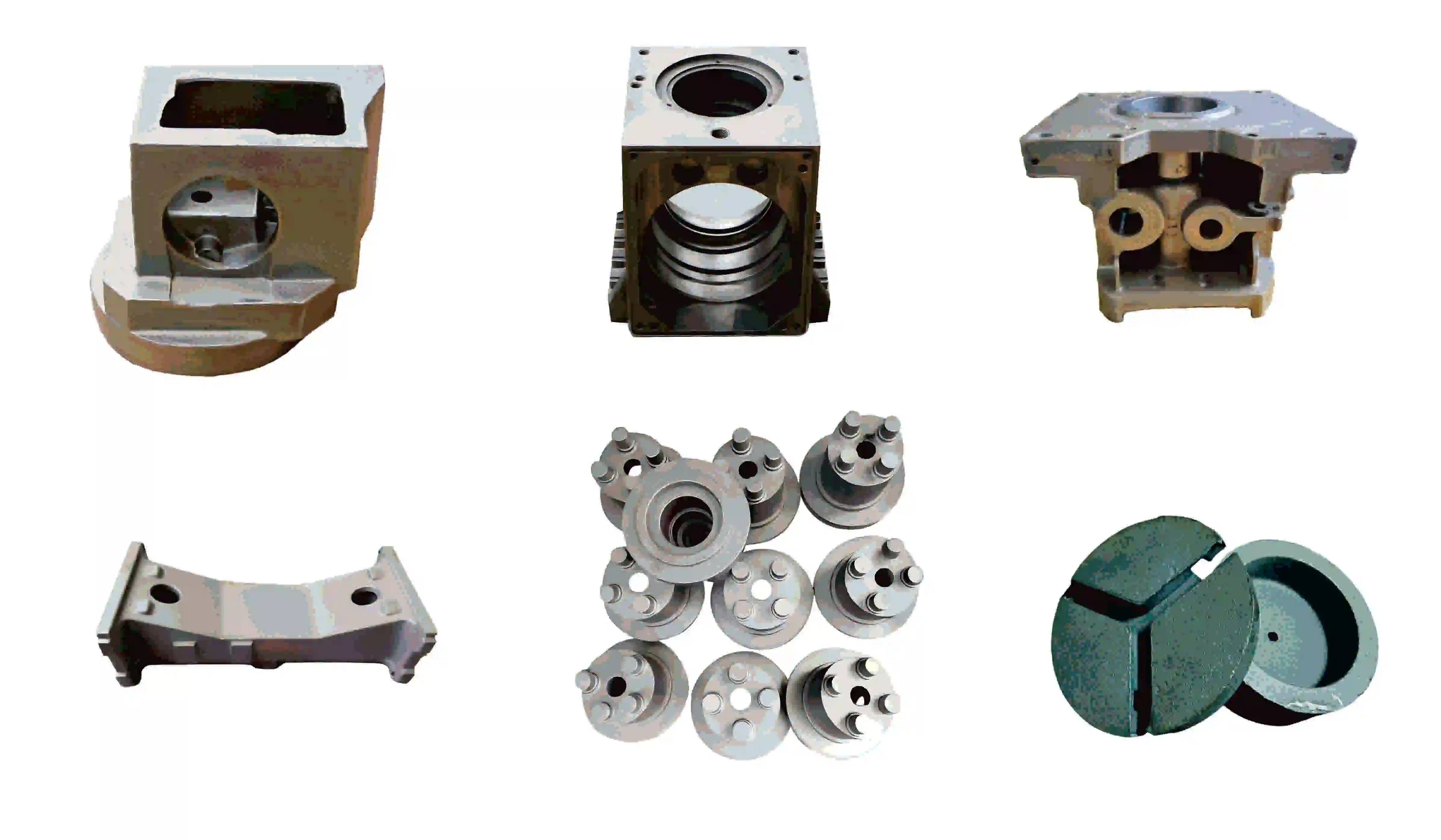

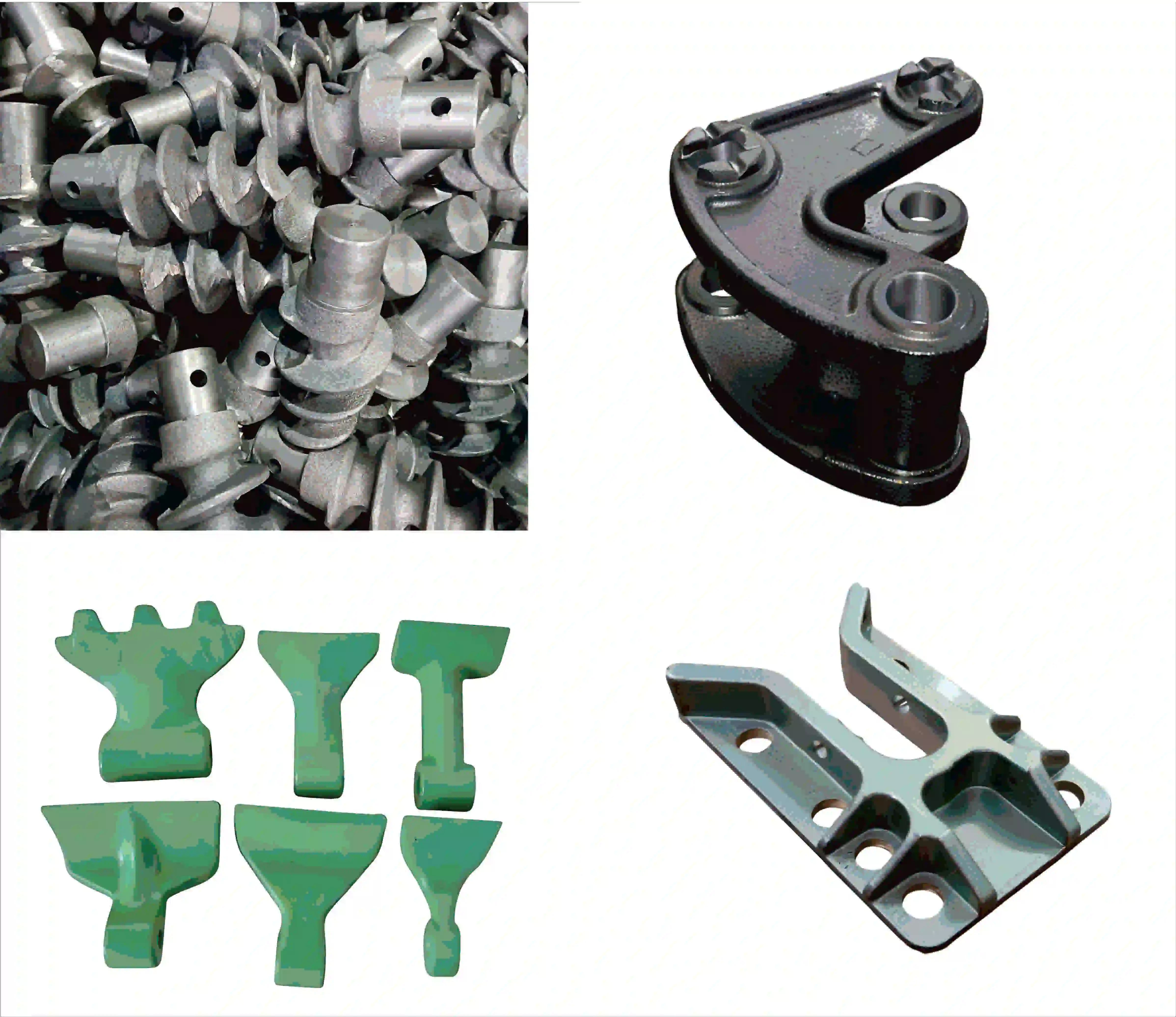

. ALD Precision Manufacturing Co., td. specializes in providing high-quality casting and precision machining prod.ucts for industries such as automotive,rail transportation, new energy vehicles, and solar photovoltaic, We supplycustomized cast iron components and mechanical parts to global leading companies, including VolkswaGen, FAWCRRC, and others.

2. What types of products do you primarily produce?

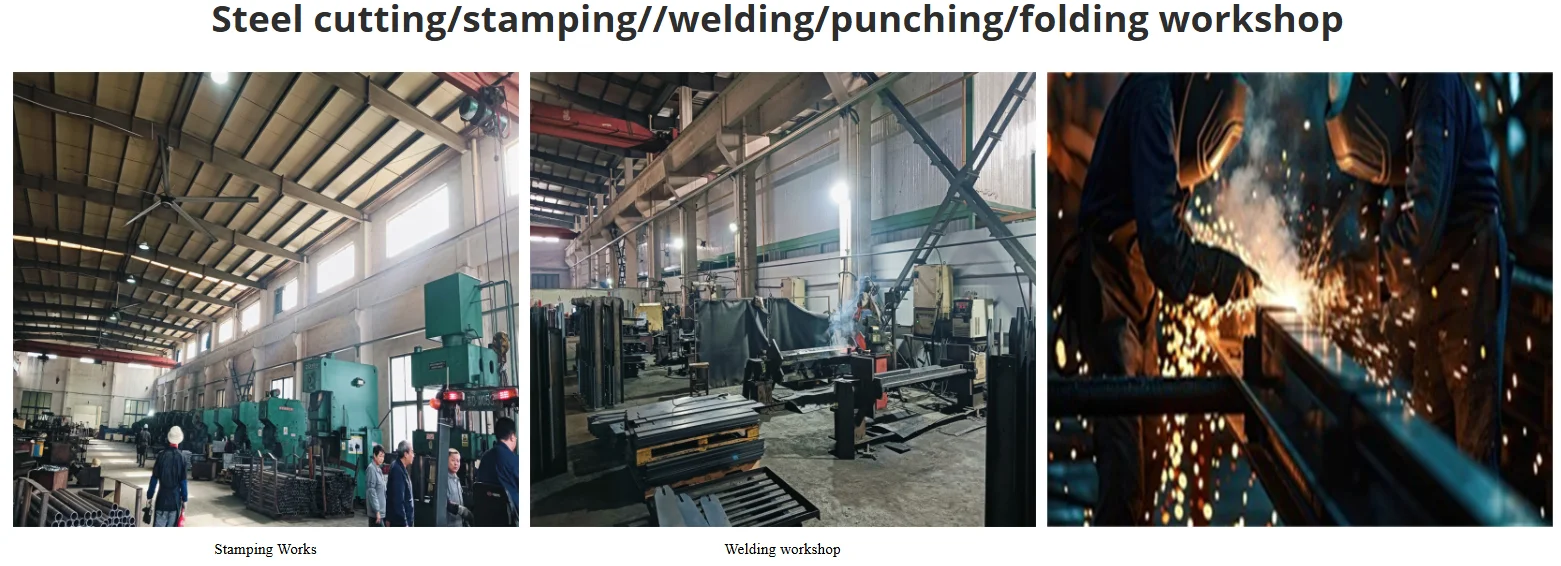

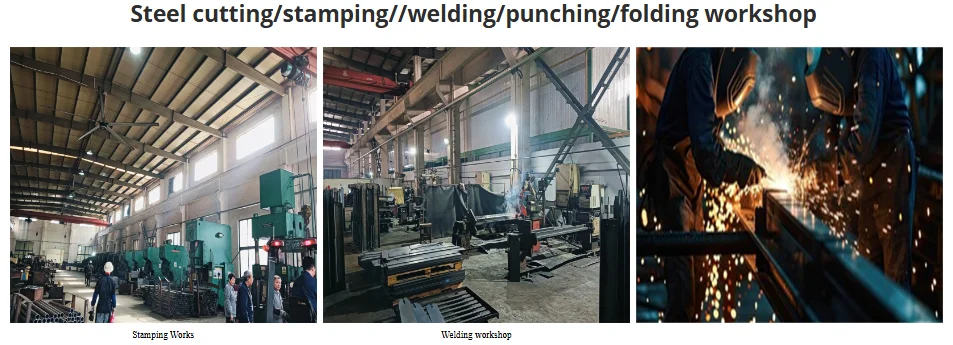

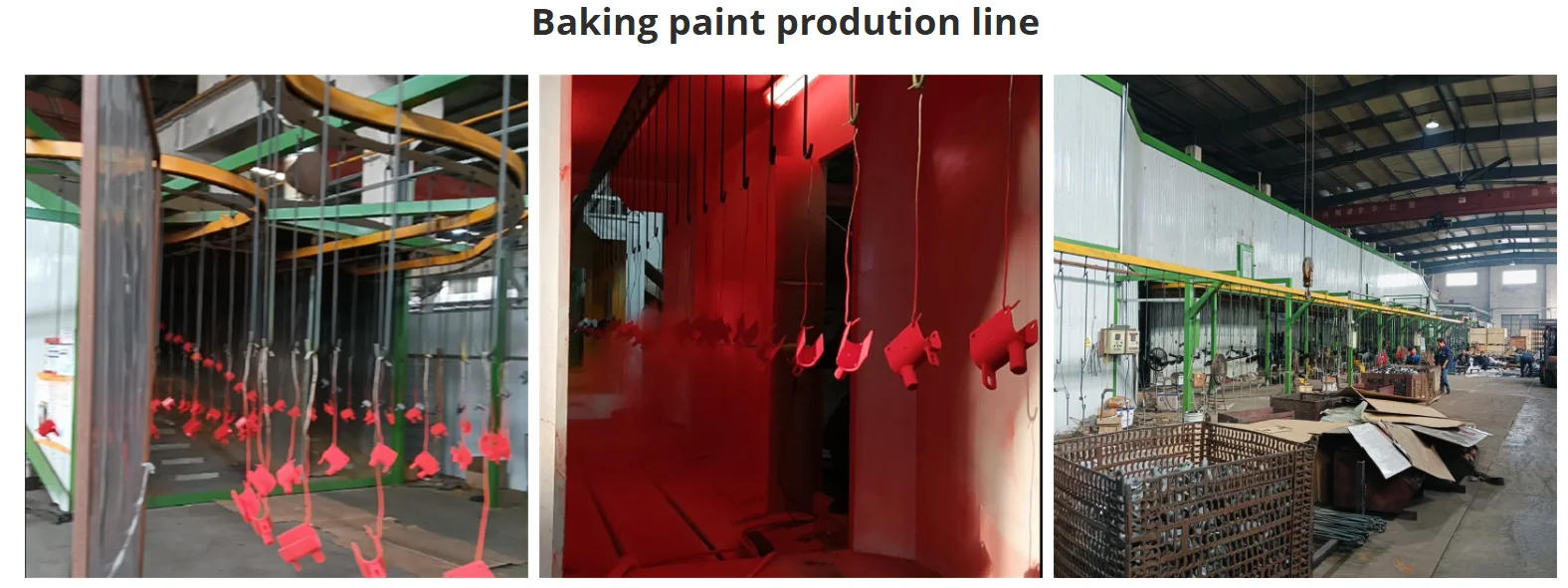

. Our main products include ductile iron, gray cast iron, and vermicular cast iron components used in automotiveparts, reducer accessories, industrial pump parts, and more. We also offer CNC precision machining, mechanical surface fnishing, mechanical baking varnish, welding, and heat treatment services.

3. Do you accept custom orders?. Yes, we specialize in custom production, We provide high-precision casting and machining services tailored toyour specific requirements, Our team will work closely with you to ensure the products meet your exact specifcationsand quality standards.

4.How do you ensure product quality?

. With 30 years of casting experience, we use advanced production equipment and rigorous quality control processes to ensure that every product meets international standards. All products undergo strict testing and quality checksbefore delivery to ensure they meet customer requirements

5. What is your typical lead time?. Our lead time depends on the order quantity and complexity. For standard orders, the typical lead time is 4 to 6weeks. For customized products, we will discuss the production schedule with you based on specifc needs.

6. Do you offer samples?

. Yes, we can provide samples to help you verify the product quality, The delivery time and cost for samples willdepend on the complexity and quantity of the products, and we can discuss these details further.

7.How do you ensure production quality for orders?

. Our quality control team closely monitors the production process to ensure that all products meet the design specifcations. Additionally, customers can request third-party inspection reports or arange for on-site inspections toensure the guality of the production.

8. What are your payment terms?

- We accept various payment methods, including Letters of Credit (/C), Telegraphic Transfer (T/T, and others. Pay.

ment terms will be negotiated based on the order amount and cooperation details.

9. Do you provide after-sales service?

. Yes, we provide comprehensive after-sales support, lf there are any quality issues with the products during useyou can contact our after-sales team, and we will provide solutions or product replacements

10.How can l get a quote?

-Please contact us through Cooig'sinquiry system ,send us your drawing and quantity,packing requirementsWe will send you a detailed quote based on your needs.