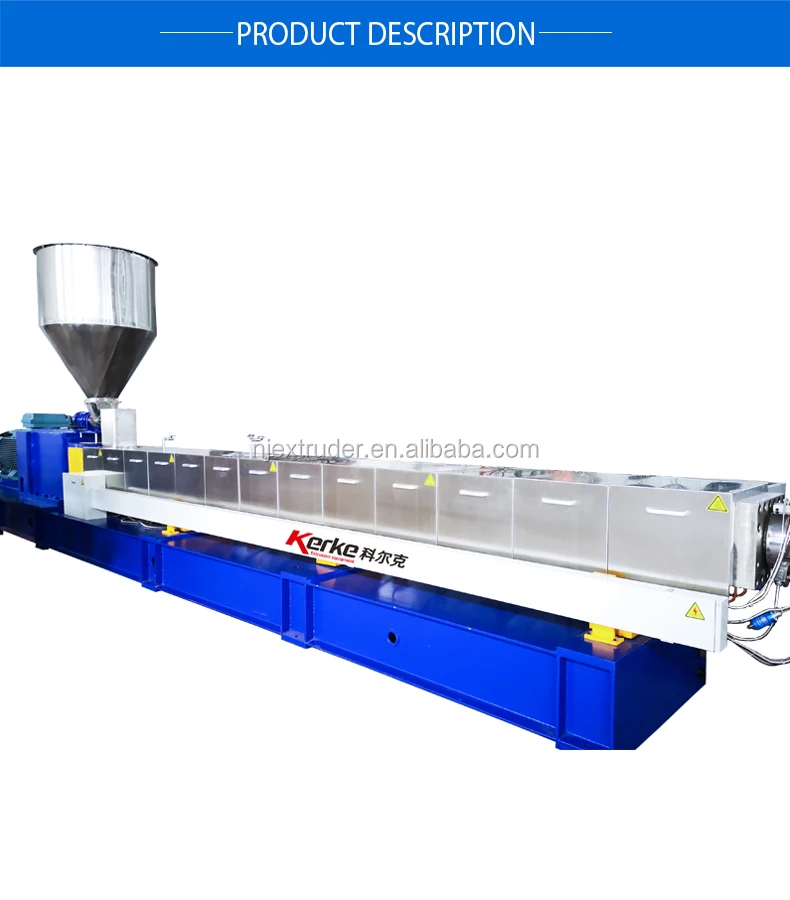

1. Komponen sekrup dirancang oleh alat bantu komputer adalah jenis memijat, memiliki fungsi membersihkan sendiri yang sangat baik, blok adonan baru

Desain secara efektif menghindari masalah terlalu panas dan konsumsi energi.

2. Sesuai dengan proses sistem dan persyaratan formula, unit dapat mengoptimalkan rasio L/D nya, struktur barel, array sekrup,

Nomor ventilasi dan lokasi, metode pemberian makan, metode kontrol listrik dll untuk alokasi wajar.

3. Sistem granulasi: pelletisasi untai pendingin air, pelat pendingin udara pemotongan panas, cincin air pemotongan panas,

Pemotongan panas kabut air eksentrik, air dan bawah air menutupi potongan panas dan sebagainya.

4. Aplikasi: mengisi modifikasi, serat kaca (serat karbon) meningkatkan berbagai jenis master batch, karet dan plastik

Compound, Aloi plastik, batch master fungsional, berbagai jenis bahan kabel listrik, ekstrusi reaktif.

Proses pengeringan, pelapisan bubuk dan sebagainya ..

PLC kabel Pvc garis ekstrusi selubung insulasi lapisan ganda mesin ekstruder ekstrusi ko-ekstrusi

PLC kabel Pvc garis ekstrusi selubung insulasi lapisan ganda mesin ekstruder ekstrusi ko-ekstrusi

Suku cadang gratis

Suku cadang gratis