[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

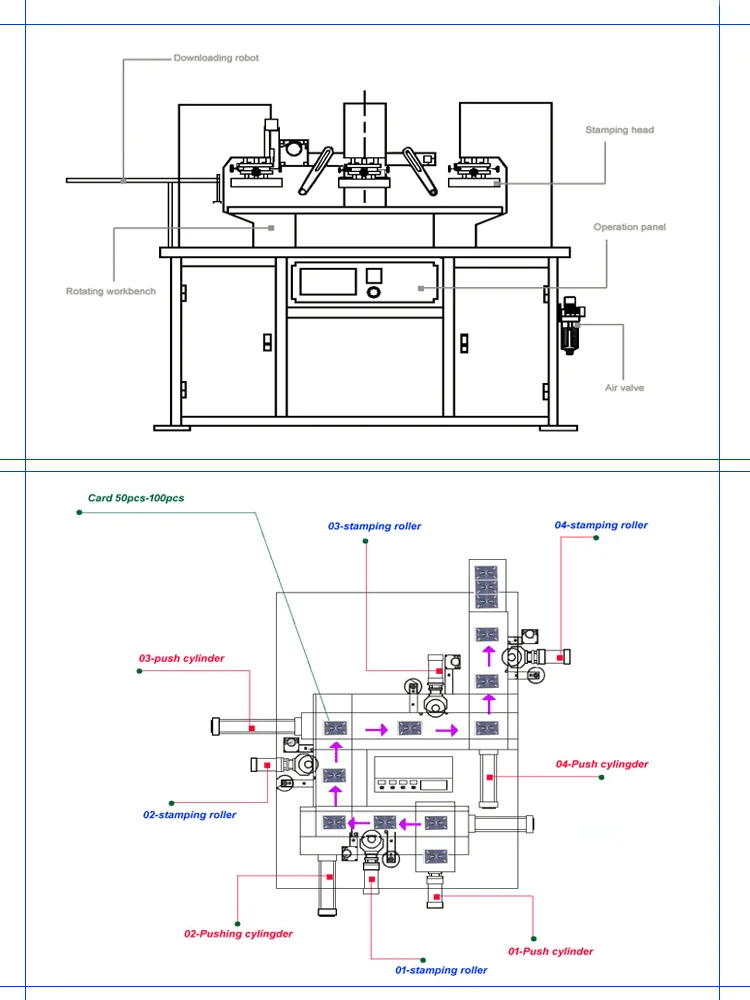

Pneumatic Flat Gilding Machine for plastic case paper bag leather logo embossing hot stamping machine

The hot stamping machine will generate huge pressure when the ironing plate and the worktable come into contact, which may cause personal injury, and adding an automatic entry and exit workbench is a common measure to prevent such damage. When the workbench slides out, products can be taken and placed, and when the workbench enters, the hot stamping is completed, preventing the operator from touching the ironing plate and the workbench.

Description:

|

Pneumatic hot stamping Machine |

||

|

Working table |

High strength Steel plate , size:420*500mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Application fields |

|

|

|

Technical parameters |

H-TC3030LN |

H-TC3035LN |

|

|

|

|

H-TC3040LN |

H-TC3045LN | |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Function |

|

|

Machine test case

Hot stamping materials

Machine details

1. What is Hot foil stamping machine?

The hot stamping machine is a special packaging and printing equipment that uses heat and pressure to transfer the metal coating on the foil film to the product. It is widely used in paper, plastic, leather, glass, wood and other products

2 . Types of hot foil stamping machines.

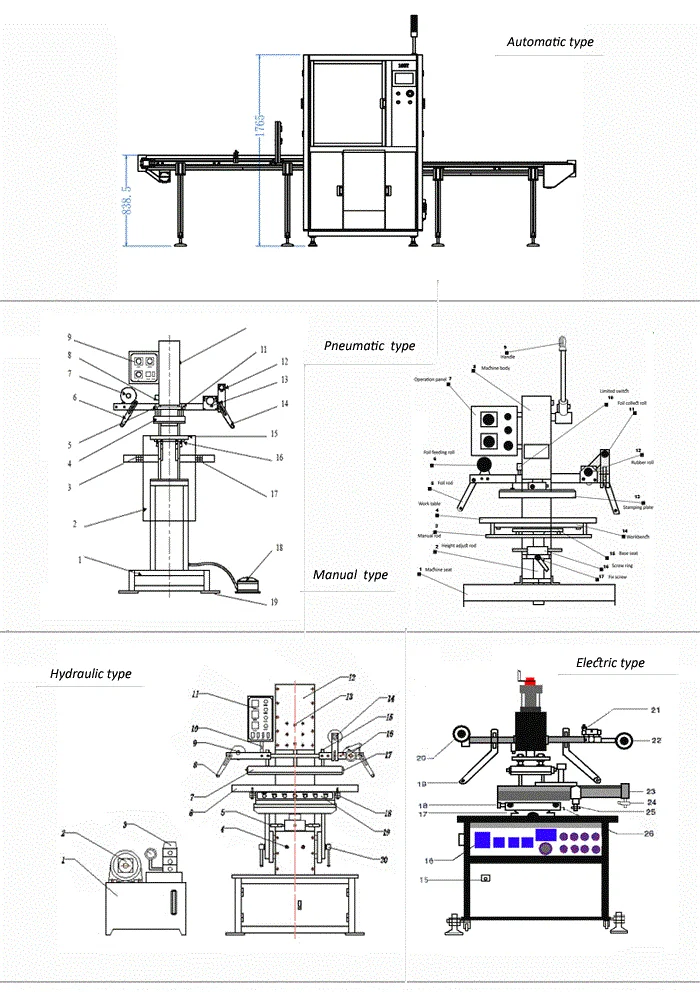

According to the power source of the hot stamping machine to generate pressure, it can be divided into manual hot stamping machine, pneumatic hot stamping machine, hydraulic hot stamping machine and electric hot stamping machine. According to the degree of automation of the hot stamping machine, it can be divided into: semi-automatic hot stamping machine and automatic hot stamping machine

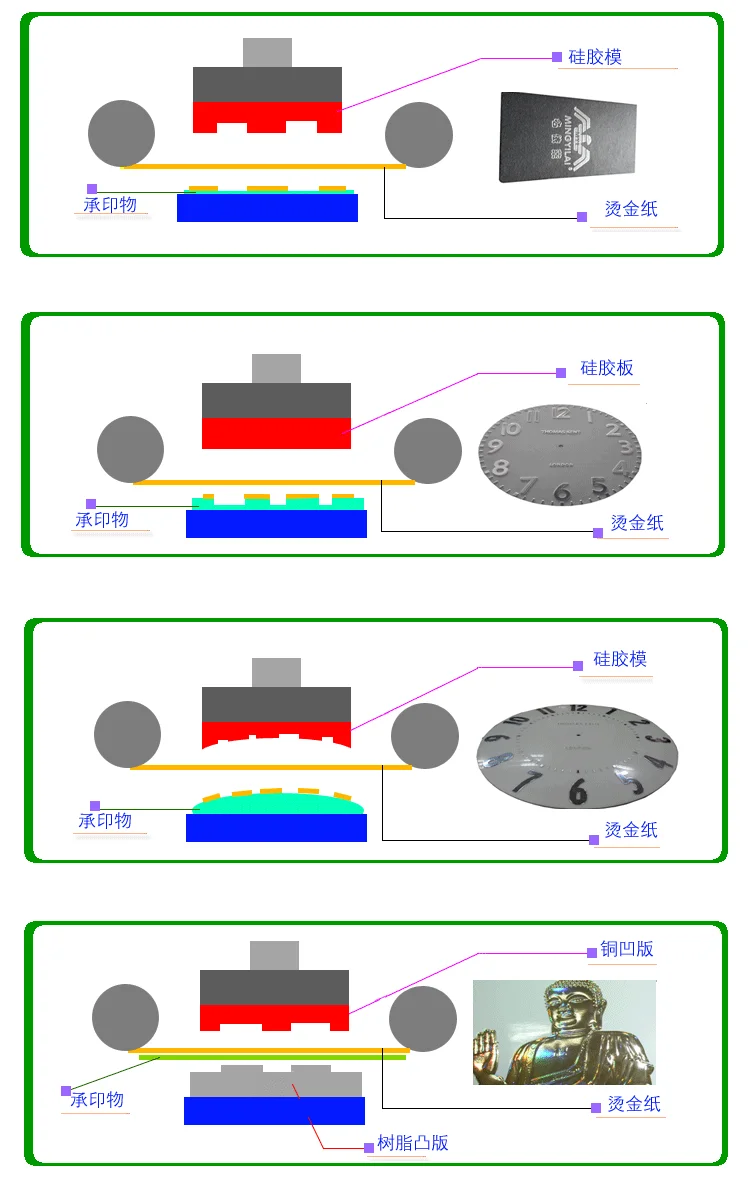

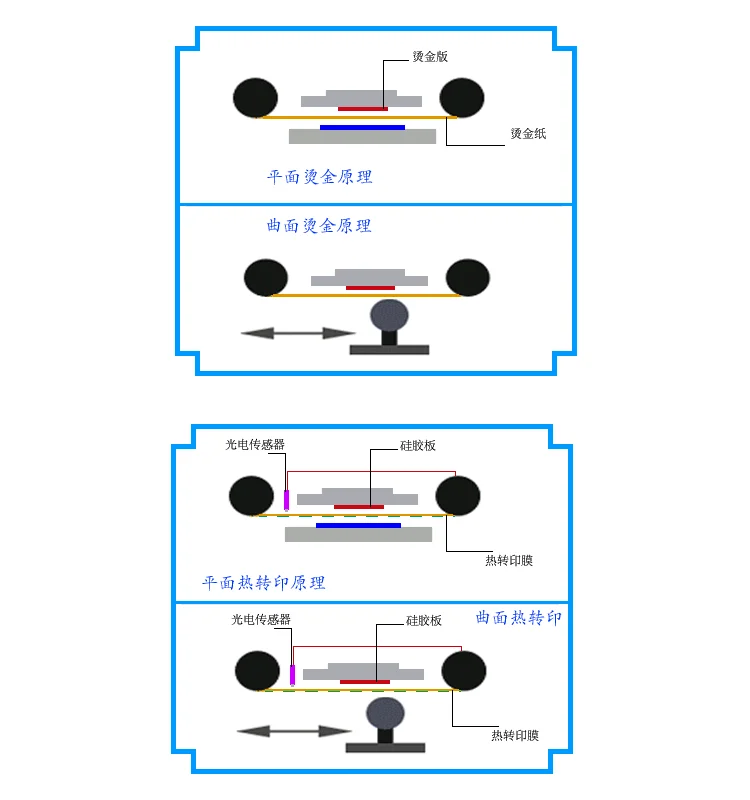

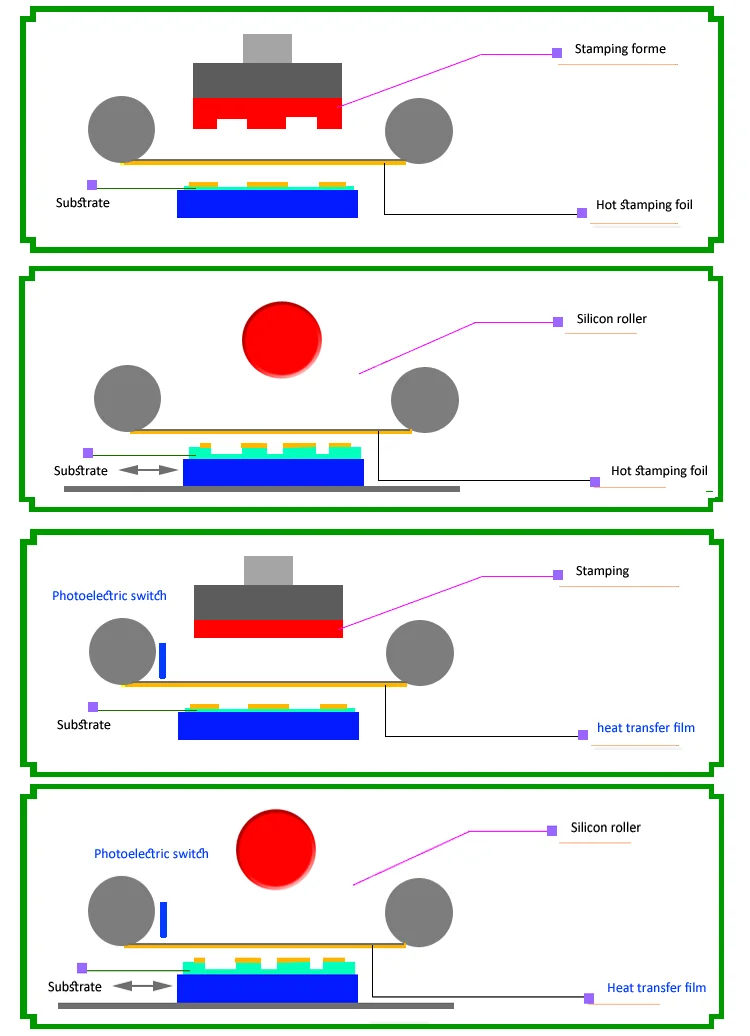

3. Foil stamping and heat transfer printing

Hot stamping and thermal transfer are closely related and difficult to distinguish on many occasions. Generally speaking, machines that use anodized aluminum can be called hot stamping machines, machines that use printed transfer films are called heat transfer machines, and machines that use heat transfer films are usually Photoelectric switches will also be installed to identify the pitch points of the thermal transfer printing film to achieve the positioning function! Some people also use whether the ironing head is a flat plate or a rubber roller to distinguish between a hot stamping machine and a heat transfer machine. Obviously, it is also difficult to distinguish them in terms of the applicability of anodized aluminum and heat transfer films!

4. Hot stamping machine operating system

The ordinary hot stamping machine adopts the microcomputer control system , the high-end hot stamping machine and automatic hot stamping machine uses the PLC to carry on the control, specially the servo control system hot stamping machine or the automatic hot foil stamping machine, uses the PLC control system quite commonly.

5. Hot stamping machine movement characteristics

The actions of the hot stamping machine mainly include the entry and exit and rotation of the worktable, the rotation of products and fixtures, the up and down and rotation actions of the ironing head, and the conveying and unloading actions of the products of the automatic hot stamping machine. Most of these actions are controlled by pneumatics, and a few are controlled by hydraulics. Those that require precise control are driven by motors or servo motors. As the market continues to improve the quality of hot stamping, various automatic hot stamping machines controlled by precision instruments have emerged!

6. How to evaluate the quality of the hot stamping machine?

Hot foil stamping machine technology content is low, more and more enterprises began to produce and sell hot stamping machines, hot stamping machines of uneven quality, how to evaluate the quality of hot stamping machine is essential. As the majority of brand-name hot stamping machine is not sold through the network, so, through Cooig sales of hot stamping machines are low-end hot stamping machine.

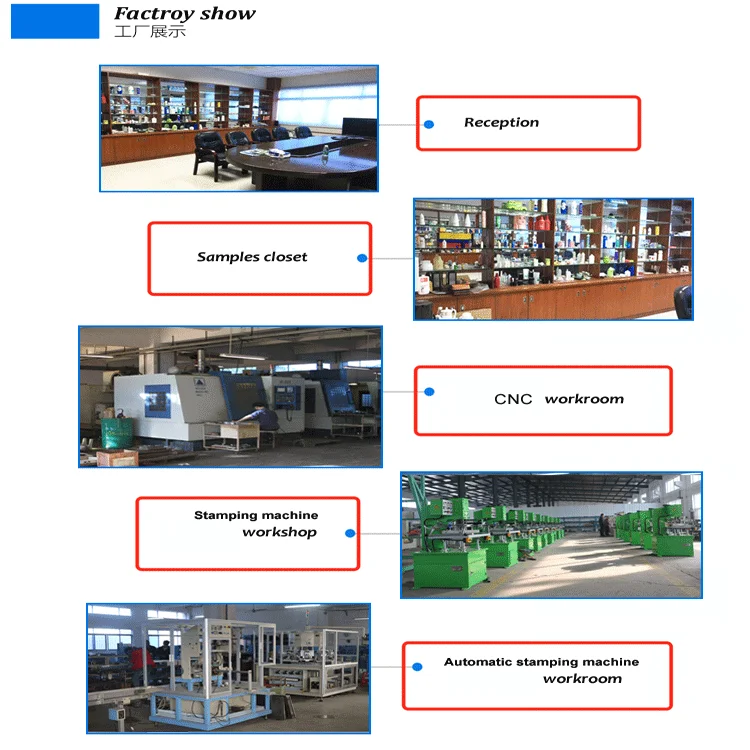

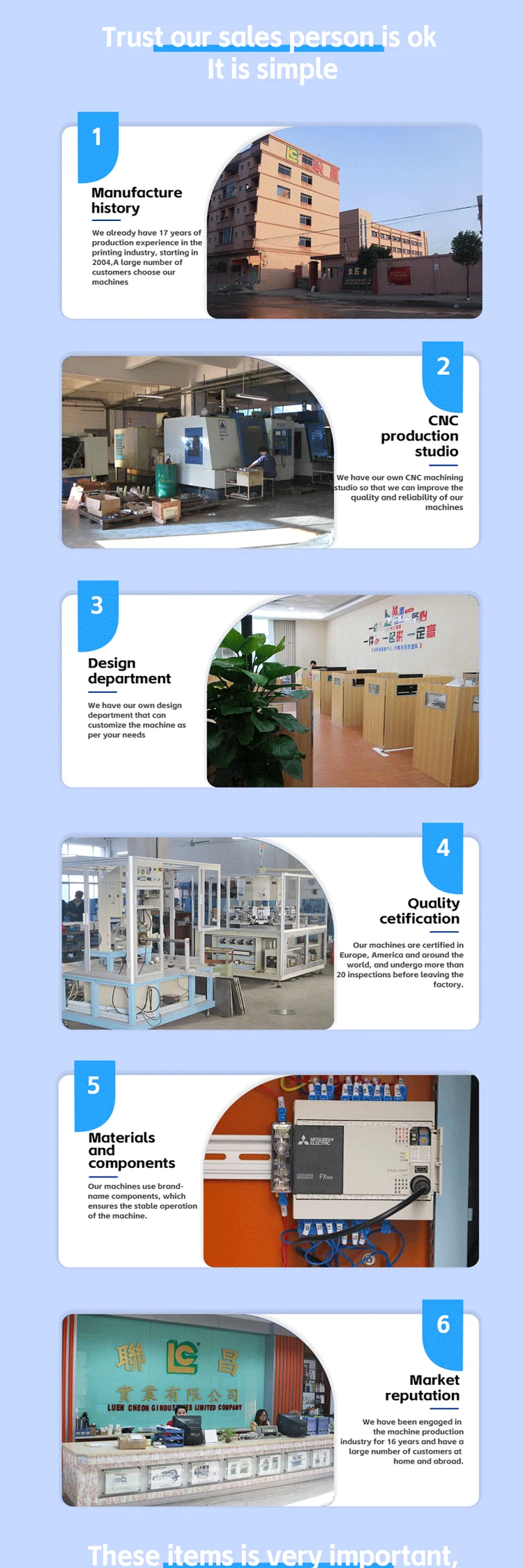

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the hot stamping machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. How to choose hot stamping die?

There are two main types of hot stamping plates, one is made by engraving copper plates, and the other is made by pressing silicone rubber. Copper plates are often used for printing substrates with softer materials, such as paper, leather, wood, and cloth; silicone plates are often used for printing substrates with relatively hard materials, such as glass, ceramics, plastics, and metals. For cold stamping processes, silicone rubber plates are also commonly used.

1) What are your main products?

Pad printers,

Silk screen printers,

Hot stamping machines,

and the supply chain related to the above-mentioned industrial printing, we will also provide users with complete printing solutions.

2) What kind of pre-sale service do you provide.

Free technical consultation, pictures, technical materials, and video materials are provided. For those that cannot be provided, we may provide design solutions.

3) What kind of payment method should I choose?

For new users, if the amount is smaller, you can use the credit guarantee order, TT, and if the amount is larger, you can consider a letter of credit. In order to protect the safety of customers' funds, we do not recommend customers to transfer to personal accounts, or use Western Union, paypal and other personal payment methods. Unless the customer makes a special request.

4) How to order the machine?

When you confirm to buy the machine, we will provide PI, and pay according to the payment method guided by PI. We will produce the machine and arrange the calculation until you get the machine safely.

5) Questions about proofing?

For direct users, it is very important to confirm whether the machine is suitable for their products and require the factory to carry out proofing as the standard for machine delivery, because pad printing machines, screen printing machines and hot stamping machines usually require fixtures, printing plates, and inks. The perfect match of the bronzing paper can meet the requirements. For the proofing of the customer's confirmed order, we are free. For the proofing without the confirmed order, we will charge a certain proofing fee. When you confirm the order, the proofing fee will be deducted from the machine purchase price.

6) How about after-sales service?

Companies that sell through the Internet are usually small in scale, and none of them have set up after-sales service points overseas. After-sales service requires online support from sales staff. In general, pad printers, screen printers and hot stamping machines are relatively simple machines, and most problems can be solved through online communication.

7) How do you evaluate the quality of your products?

When each user purchases a product, he balances price and quality. This balance may be difficult to grasp, but this is how you do business. Most of the products sold on the Internet are in the middle of whether the price is not low or the quality is not bad. end. You have to negotiate professionally with the sales staff for better products. There are roughly 300 similar manufacturing plants and more than 8,000 trading companies in China. It is not difficult to choose products that suit you.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan