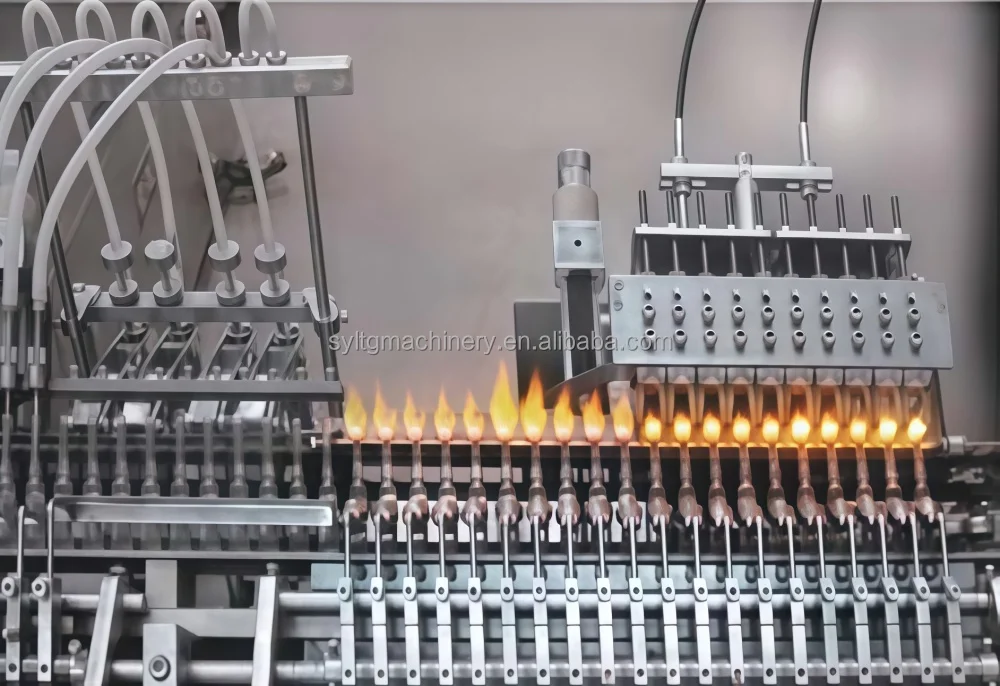

Large-scale hydrogen-oxygen generator paired with filling and sealing machine - Applied for the automatic wire-drawing sealing of water injections

(1) Remarkably cut costs. Compared with the liquefied gas sealing method, it can save over 40% of the costs.

(2) Enhance quality to meet the requirements of GMP certification and product export. When using liquefied gas for sealing, its combustion generates carbides, sulfides, and other harmful gases that impact product quality. These gases have a higher molecular weight than air, so a small amount of them will be sealed inside the bottles, thereby affecting the quality, for which strict requirements are imposed. When sealing with a hydrogen-oxygen flame, the complete combustion of hydrogen and oxygen only produces a small amount of water vapor without any polluting gases. Moreover, the water vapor quickly escapes upward in the air and won't be sealed in the medicine bottles. Therefore, it fully complies with the requirements of GMP certification and export.

(3) Improve the sealing pass rate and sealing speed. The hydrogen-oxygen flame is concentrated, and its thermal energy utilization efficiency is 1.5 times that of liquefied gas. When using the hydrogen-oxygen flame for sealing, the sealing pass rate can reach 99%, and the sealing speed can be increased by approximately 5%.

Suku cadang gratis

Suku cadang gratis