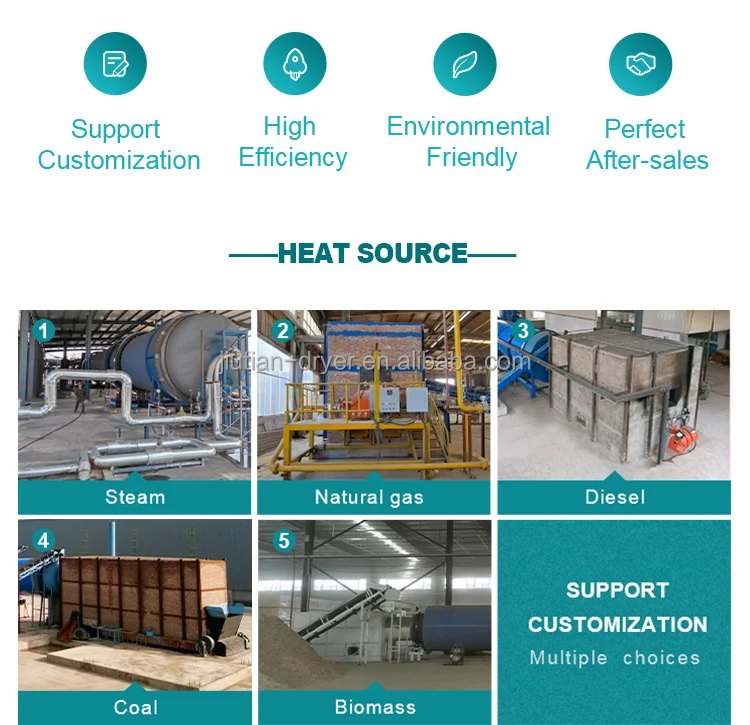

Jiutian brewer's grains dryer mainly consists of a heat source, feeding machines, feeder, rotary drum, discharging machine, draftfan, discharge and power distribution cabinet.

Production process: BSG with 85% moisture are delivered into the screw dehydration machine (or belt dehydration machine) and dehydrated to 50% to 60% moisture. Then the dehydration product was delivered into the rotary dryer by screw conveyor for the dehydration process. High-temperature air heated by furnace could have full material and heat exchange with BSG, taking away the moisture. The dry materials could pass through the drum quickly with the air force. Wet materials would be dropped gradually and get the fully dried. The eventual dry materials would be delivered out of the systems through screw conveyor.

The new product line could fulfill continues and stable production and has the characterization of low cost, easy installation and maintenance, and less need for labor. Meanwhile, the product moisture of the dehydration process and drying process could separately approach 50-65% and 12%, which is satisfying. According to the test report of national feed quality supervision, inspection and test center, the nutrient in BSG will not lose in the process of dehydration and drying. Currently, we could provide a different series of drying equipment to meet the demand of different beer suppliers.

Suku cadang gratis

Suku cadang gratis