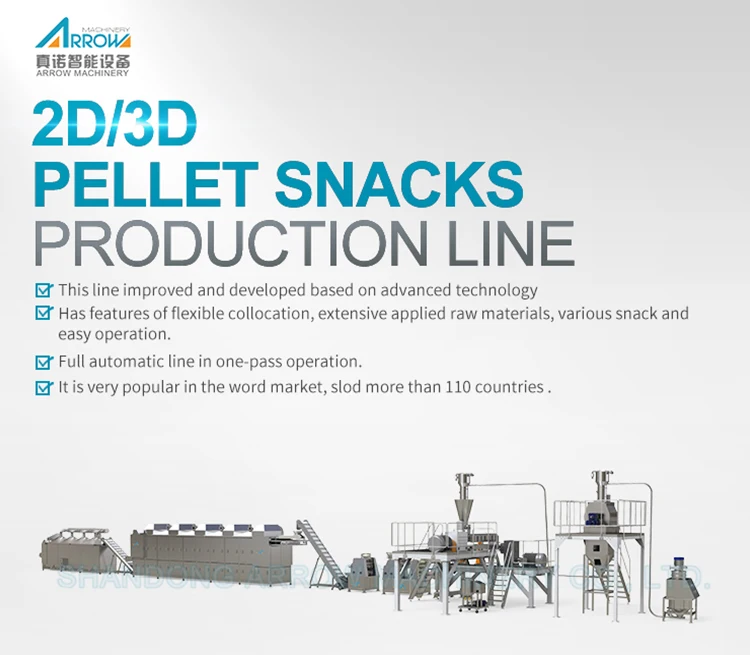

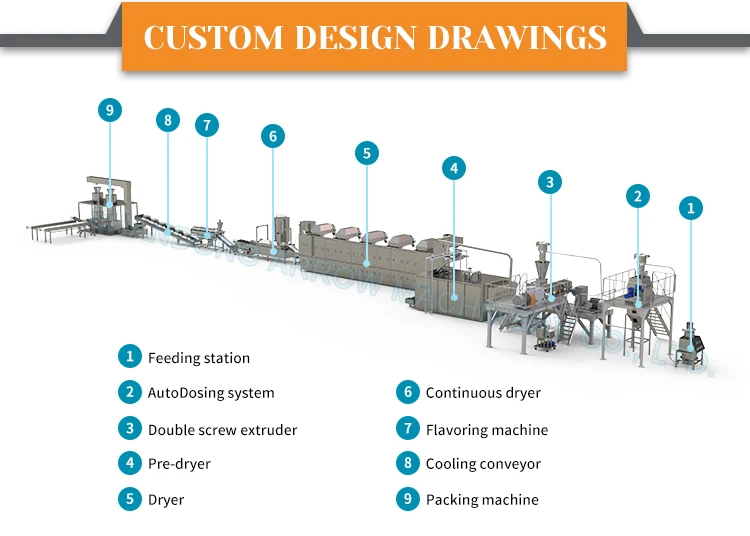

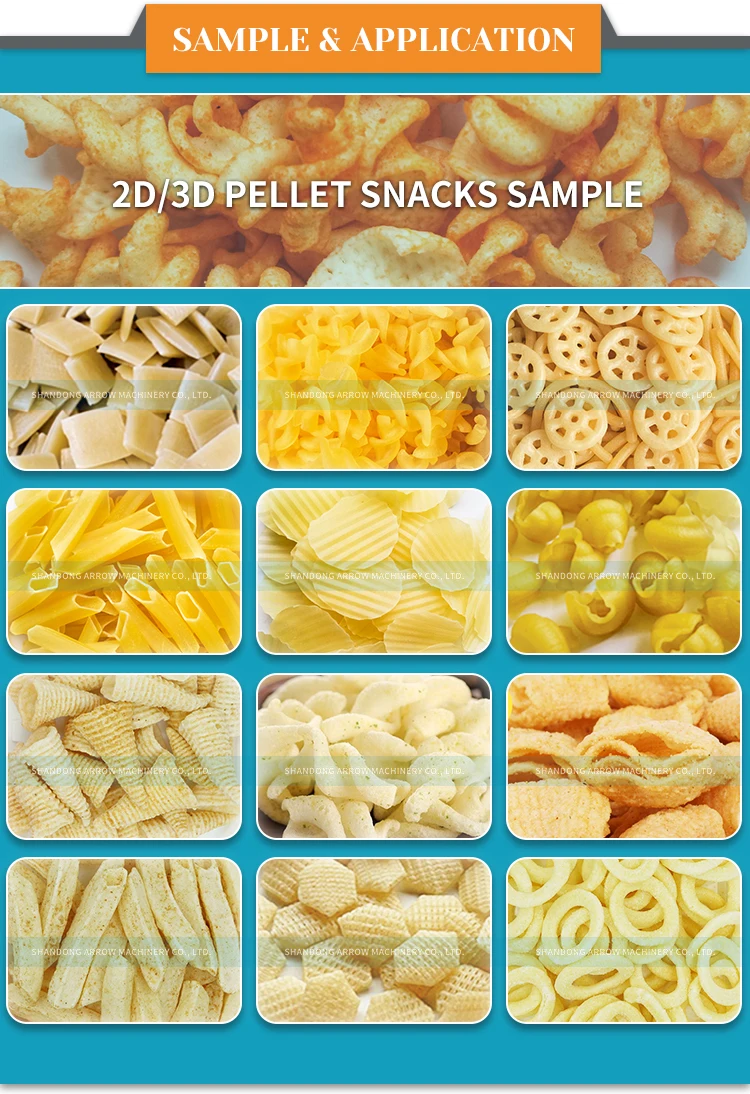

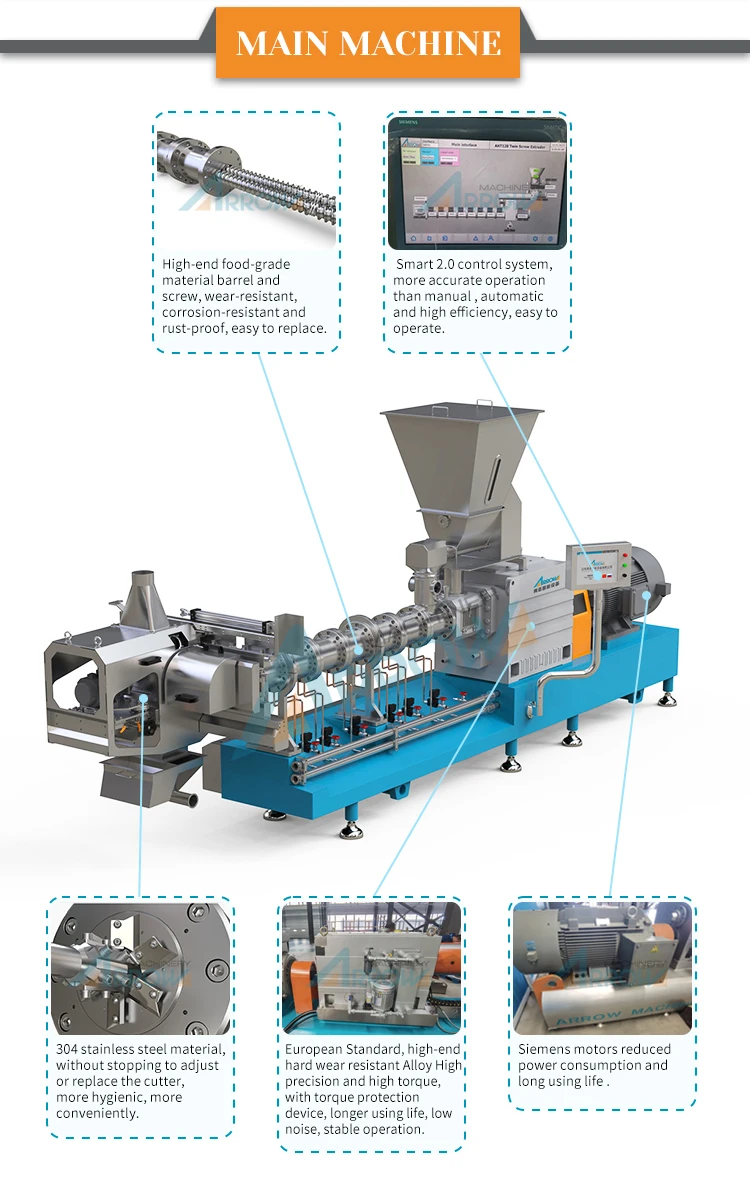

1. Easy to control with automatic production line.2. There is a wide range of raw materials to produce different products by only one production line.

3. Using corn or rice as the raw material, which has the benefit of being easy to get and low cost.

4. Full use of the raw materials without waste.

5. Adjustable feeding speed according to the production requirements.

6. Various products of different shapes by replacing mold easily.

7. The cutting device of the extruder has a cover to ensure safe operation.

8. Adjustable baking or drying temperature and time.

9. Equipped with the temperature display and control device.

10. Insulation device can improve thermal efficiency.

11. Optional round and rectangular product cutting machine according to requirements.

12. Flexible configurations to meet different production, budget and workshop's layout requirements.

13. Integrated, safe and hygienic seasoning drum.

14. The equipment of the whole production cycle is made of stainless steel which is hygiene and easy to clean.