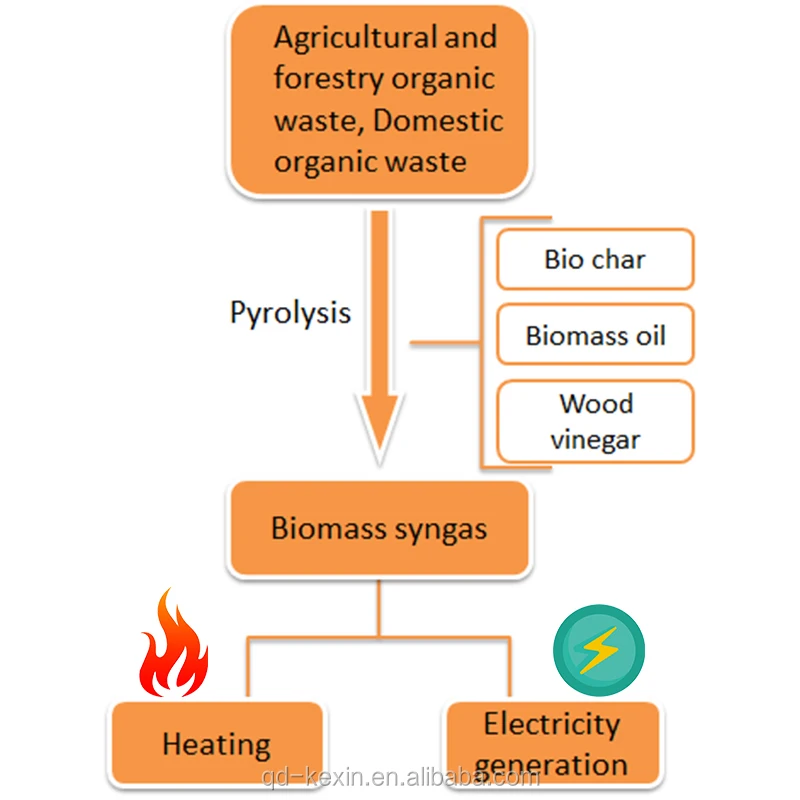

Generation principle of biomass syngas: biomass raw material enters the reactor of gasifier, is heated and dried, and then with the temperature rising, its volatile matters are separated out and pyrolyzed (cracked) at high temperature. The pyrolyzed gas and biomass react with the air supplied in the oxidation zone to generate CO2 and water vapor. The heat generated by combustion is used to maintain drying, pyrolysis and lower part Endothermic reaction in the original region. The gas generated after combustion reacts with high temperature carbon layer through reduction zone (c + CO2 = 2CO, C + HO2 = H2 + CO) to generate biomass synthesis gas containing Co, H2, CH4, CMHN and other components, which is led out from the lower part and sent out for use after removing impurities such as tar through purification system. The ash is discharged from the lower part of the gasifier.