The ODD AUTOS TRADING COMPANY LLC began in the 2011 with hundreds of manufacturers pioneering the horseless carriage. Early car manufacturing involved manual assembly by a human worker. The process evolved from engineers working on a stationary car, to a conveyor belt system where the car passed through multiple stations of more specialized engineers. Starting in the 1960s, robotic equipment was introduced to the process, and most cars are now mainly assembled by automated machinery.

For many decades, the United States led the world in total automobile production, with the U.S. Big Three General Motors, Ford Motor Company, and Chrysler being the world's three largest auto manufacturers for a time, and G.M. and Ford remaining the two largest until the mid-2000s. In 1929, before the Great Depression, the world had 32,028,500 automobiles in use, of which the U.S. automobile enterprises produced more than 90%. At that time, the U.S. had one car per 4.87 persons.[7] After 1945, the U.S. produced around three-quarters of the world's auto production. In 1980, the U.S. was overtaken by Japan and then became a world leader again in 1994. Japan narrowly passed the U.S. in production during 2006 and 2007, and in 2008 also China, which in 2009 took the top spot (from Japan) with 13.8 million units, although the U.S. surpassed Japan in 2011, to become the second-largest automobile industry. In 2023, China had for the first time in history more than 30 million produced vehicles a year, after reaching 29 million for the first time in 2017 and 28 million the year before. From 1970 (140 models) over 1998 (260 models) to 2012 (684 models), the number of automobile models in the U.S. has grown exponentially.

Safety is a state that implies being protected from any risk, danger, damage, or cause of injury. In the automotive industry, safety means that users, operators, or manufacturers do not face any risk or danger coming from the motor vehicle or its spare parts. Safety for the automobiles themselves implies that there is no risk of damage.

Safety in the automotive industry is particularly important and therefore highly regulated. Automobiles and other motor vehicles have to comply with a certain number of regulations, whether local or international, in order to be accepted on the market. The standard ISO 26262, is considered one of the best practice frameworks for achieving automotive functional safety.[9]

In case of safety issues, danger, product defect,[10][11] or faulty procedure during the manufacturing of the motor vehicle, the maker can request to return either a batch or the entire production run. This procedure is called product recall. Product recalls happen in every industry and can be production-related or stem from raw materials.

Product and operation tests and inspections at different stages of the value chain are made to avoid these product recalls by ensuring end-user security and safety and compliance with the automotive industry requirements. However, the automotive industry is still particularly concerned about product recalls, which cause considerable financial consequences.

The global automotive industry is a major consumer of water. Some estimates surpass 180,000 L (39,000 imp gal) of water per car manufactured, depending on whether tyre production is included. Production processes that use a significant volume of water include surface treatment, painting, coating, washing, cooling, air-conditioning, and boilers, not counting component manufacturing. Paintshop operations consume especially large amounts of water because equipment running on water-based products must also be cleaned with water

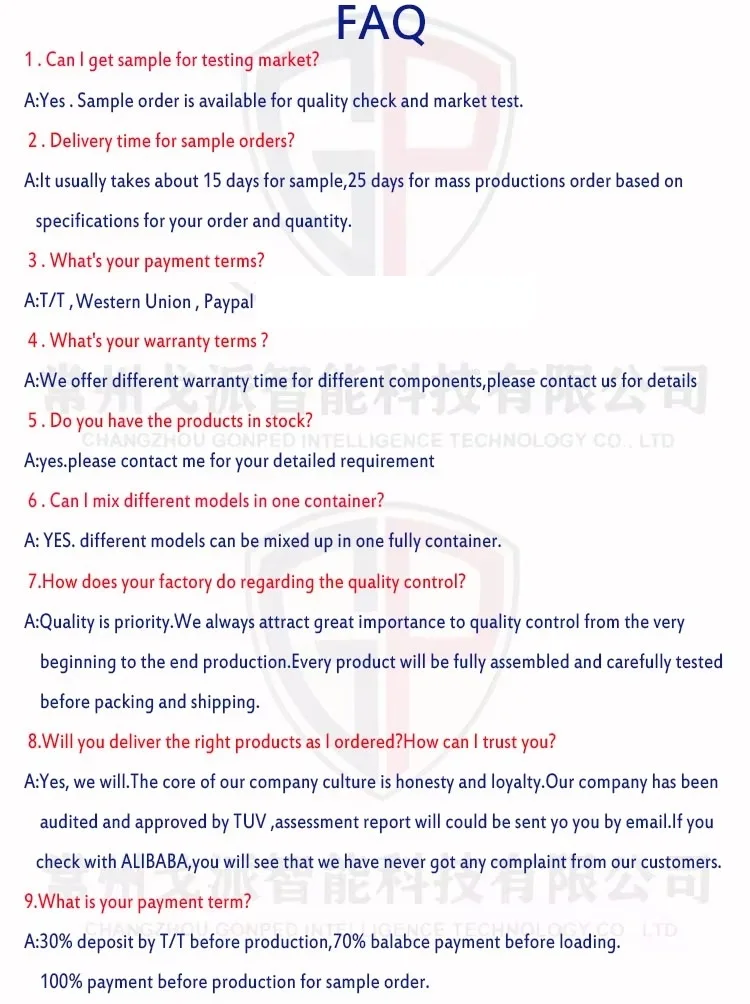

In 2022, Tesla's Gigafactory Berlin-Brandenburg ran into legal challenges due to droughts and falling groundwater levels in the region. Brandenburg's Economy Minister Joerg Steinbach said that while water supply was sufficient during the first stage, more would be needed once Tesla expands the site. Regards customer