Q1:Is Selective Pallet Racking Same as the Teardrop Pallet Racks?

A1:Selective racking is the standard version. On the other hand, teardrop racks are just one type of these racks.

Q2:Layout of Selective Pallet Racking?

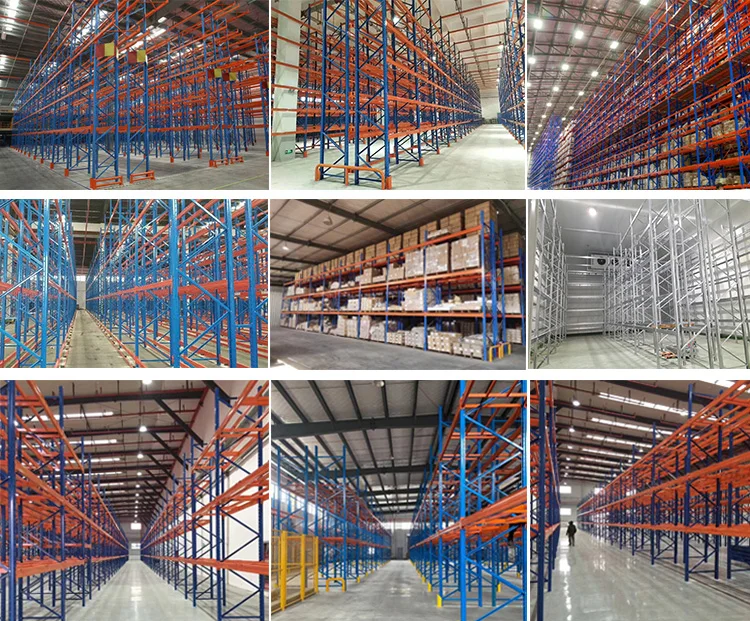

A2:The layout of a selective rack is strict to one pallet deep. This limits you to only place two back-to-back racks.

Q3:Can the Selective Pallet Racking be easily adjusted or expanded in the future?

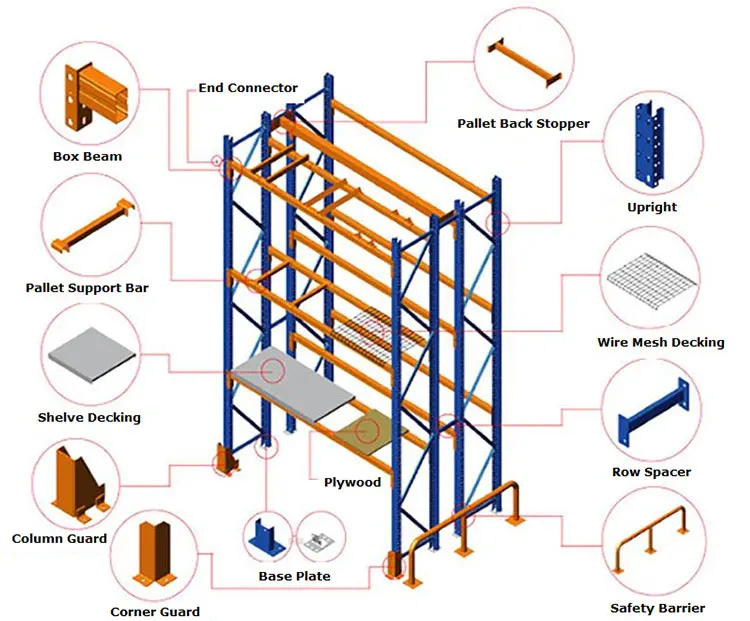

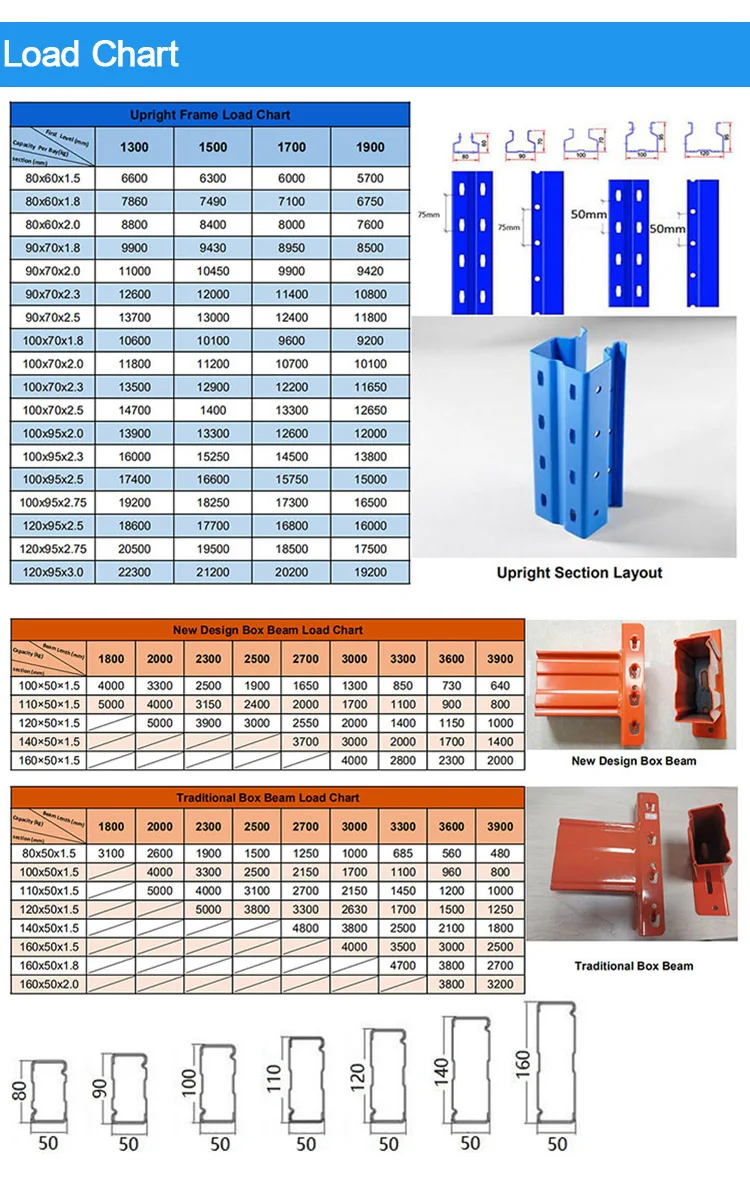

A3:The beams are inserted into the uprights, making disassembly very convenient. The spacing of each hole in the uprights is 50mm/75mm, and the minimum adjustment distance for rack height is 50mm/75mm. You can extend the depth of the rack by adding additional frames, typically up to 30 additional frames. However, in theory, it can be expanded indefinitely.

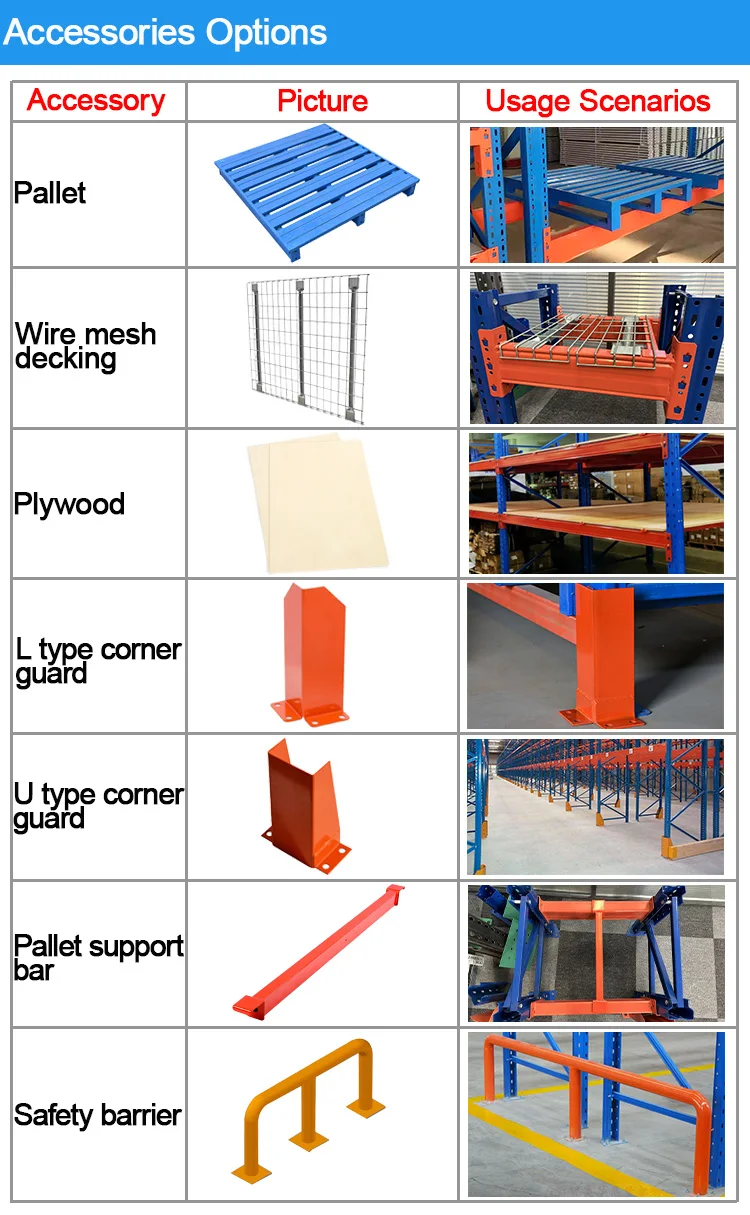

Q4:What Safety Accessories Are Included with the Selective Pallet Racking?

A4:Bottom angles, diagonal braces, horizontal braces, foot guards, guardrails, rear load beams, safety bolts, back mesh, pallet stops, cargo dividers, mesh panels, pallet supports, anti-roll drums, signage and warnings, intermediate struts, and shims are all included.

Q5:How Does the Selective Pallet Racking Ensure Proper Load Distribution and Stability?

A5:Our professional design team calculates and analyzes the rigidity, strength, and torque of the steel, taking into account permanent, variable, and accidental loads, as well as the effects of perforations, local buckling, global buckling, distortion buckling, and defects. In simple terms, the design of beams and uprights helps distribute loads evenly. Diagonal and horizontal braces provide stability to the structure.

Q6:What Products Are Suitable for Selective Pallet Racking?

A6:Pallet racking is suitable for storing a variety of large quantities of items, as well as single-item bulk storage. For example, it can be used for storing food, clothing, pharmaceuticals, parcels, packaging materials, automotive parts, and more.