[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

Suku cadang gratis

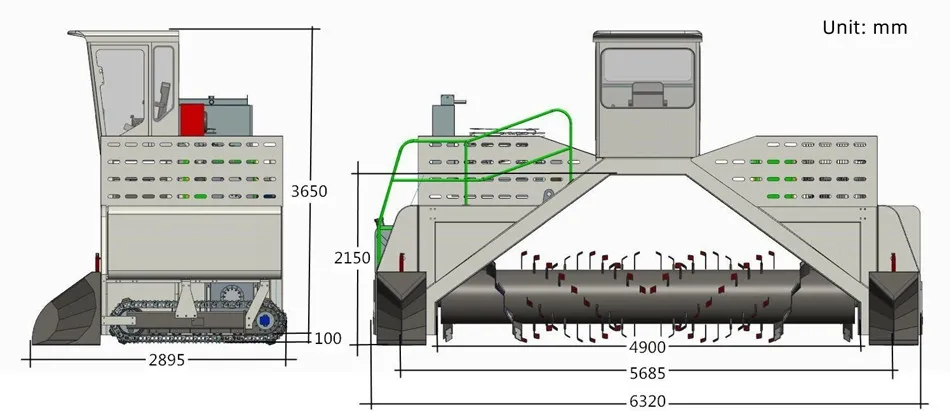

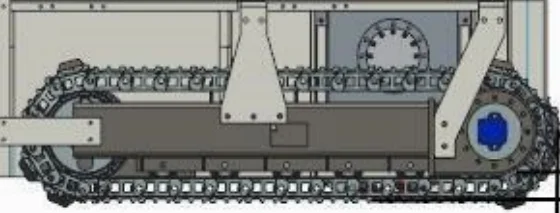

Model | YHFDJ-2400 | YHFDJ--2600 | YHFDJ--2800 | YHFDJ--3000 |

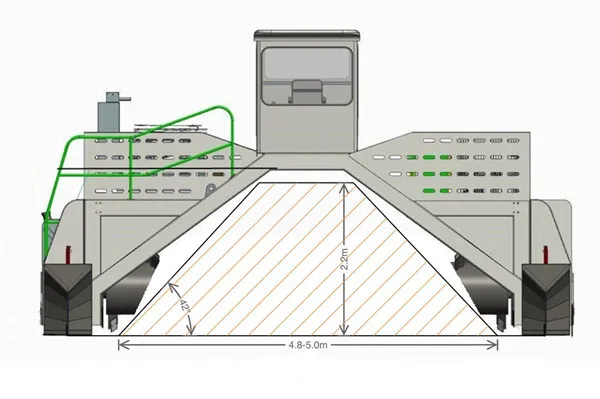

Turning Width(mm) | 2400 | 2600 | 2800 | 3000 |

Turning Depth(mm) | 600-1000 | 1000-1300 | 1100-1400 | 1300-1500 |

Windrow Spacing (mm) | 800-1000 | 800-1000 | 800-1000 | 800-1000 |

Maximum Diameter of Material Particles (mm) | 250 | 250 | 250 | 250 |

Horsepower(hp) | 85 | 116 | 123 | 156 |

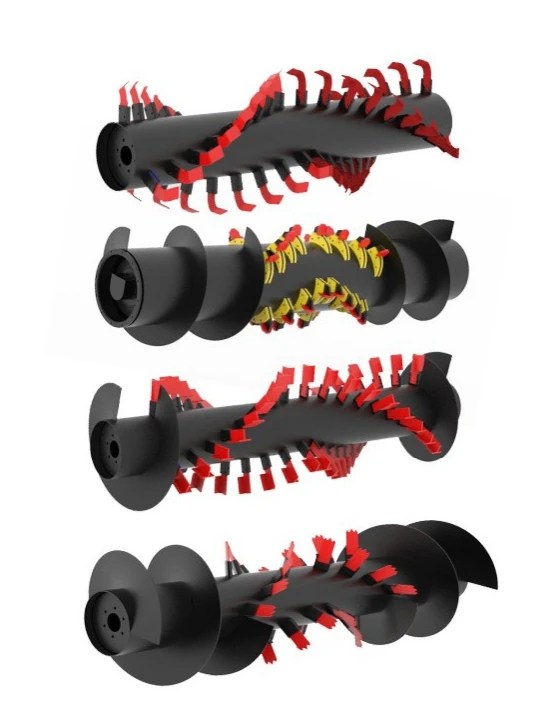

Working Knife Diameter(mm) | 400 | 500 | 500 | 500 |

Working Speed (m/min) | 6-10 | 6-10 | 6-10 | 6-10 |

Capacity(m3/h) | 500-700 | 1000-1200 | 1100-1300 | 1300-1500 |

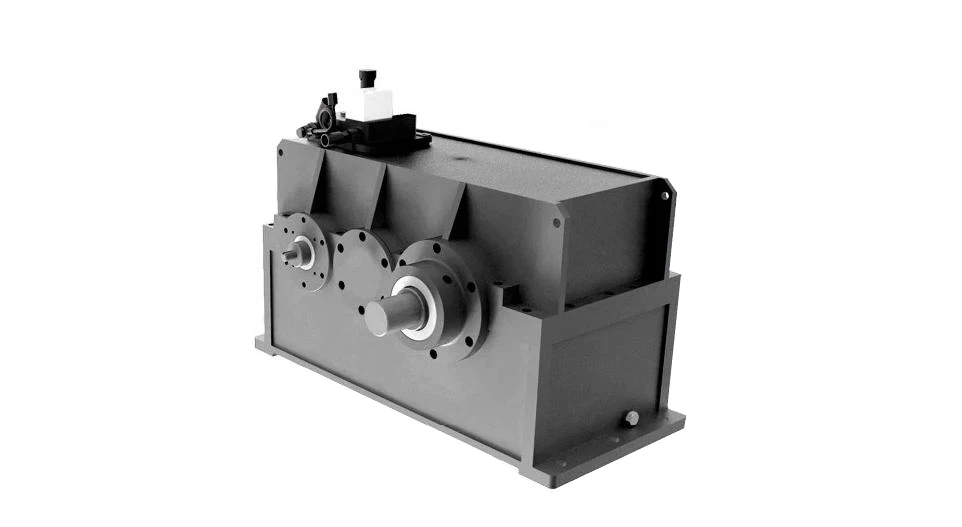

Brand | CUMMINS | Peak Torque/Speed | 1135/1500N.m/rpm |

Model | 6CTA8.3-C260-II | Cold Style | Water-cooled |

Displacement | 8.3L | Emission standard | China stage IIA |

Cylinder diameter | 114mm | Cylinder No. | 6 |

Piston stroke | 135mm | Electronic control system | ECM |

Rate speed | 2200r/min | Fuel | Diesel |

Roted Power | 194kW | Weight | 637KG |

Fuel consumption | 231g/Kw.h | Place of Origin | China |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan