[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

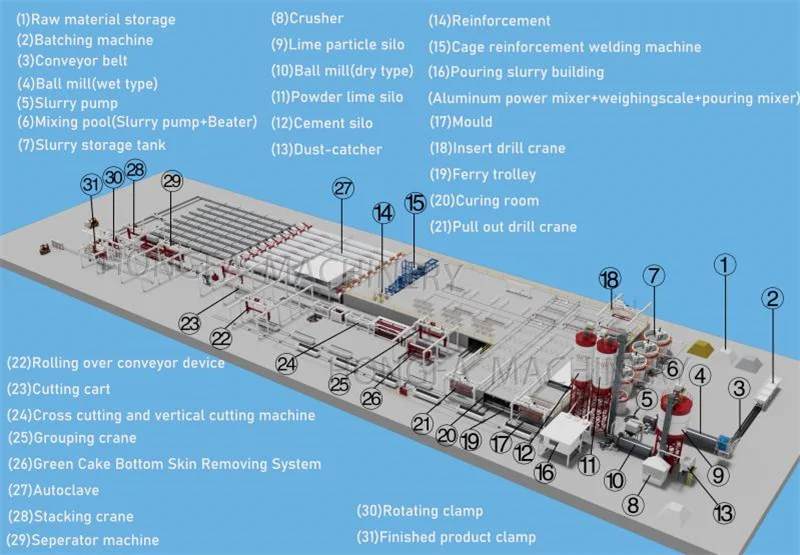

Suku cadang gratisHongfa Grounp provides worldwide customers with comprehensive technical solutions for the production of autoclaved aerated concrete (AAC). Nowadays, autoclaved aerated concrete blocks and panels are widely used in exterior walls, interior partitions, floors and roofs of various structures, and prefabricated steel buildings.

The entire production line is highly intelligent and environmentally controlled, it is a modern, high-quality autoclaved aerated concrete production plant.

Basing on the development concept of green, low-carbon, and intelligentization, we support autoclaved aerated concrete plant solution provides entire lifecycle services for worldwide customers to ensure efficient and high-quality production of AAC products.

AAC wall interlock machine low price/aac block making machine production line/aac blocks plant/ AAC PLANT ENGINEERING aac block production line

1. AAC Block from Hongfa AAC block plant

Areated concrete block (light block ) is the light and porous building material. It has light keeping temperature cant burn and other advantages.it can be made into many kinds of bricks for example:600×200×100,80×80×180, 240×115×53, 600×200×125, 600x200x120 ; 600x250x180; 600x300x240), they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

General specification

| Common specifications of block | ||

| Name | Product grade | specification:length* width* high mm |

| AAC High-precision block | B04-A2.5 B05-A3.5 B06-A5.0 | 600*250*50 |

| 600*250*75 | ||

| 600*250*100 | ||

| 600*250*150 | ||

| 600*250*200 | ||

| 600*250*250 | ||

| 600*250*300 | ||

| AAC Ordinary block | B04-A2.0 B05-A3.5 B06-A5.0 | 600*250*100 |

| 600*250*150 | ||

| 600*250*200 | ||

| 600*250*250 | ||

| 600*250*300 | ||

According to product strength and bulk density (weight per cubic meter), it is divided into different grades. Commonly used are: strength A3.5, bulk density B06. The higher the strength, the lighter the bulk density

Size deviation

ALC block (Autoclaved Lightweight Concrete Block) is also called AAC Block (Autoclaved Aerated Concrete Block) which is steel mesh reinforced, lightweight and loadbearing.

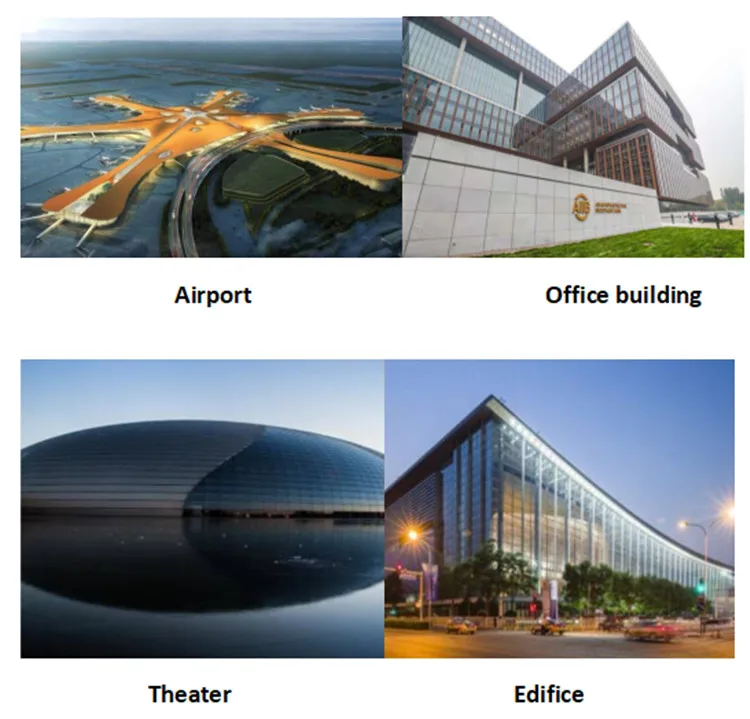

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools, supermarkets etc.

Autoclaved Aerated Concrete Block can replace traditional precast concrete and clay bricks very well. Also the panels can easily cut, drilled, screwed when installing with fast speed due lightweight and precast.

2. Application

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools, supermarkets etc.

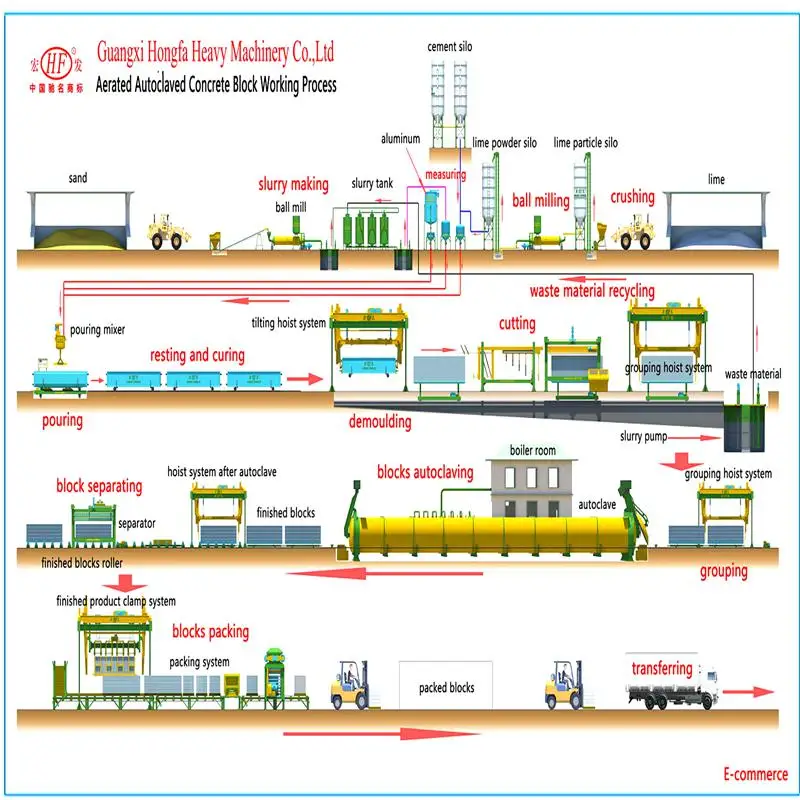

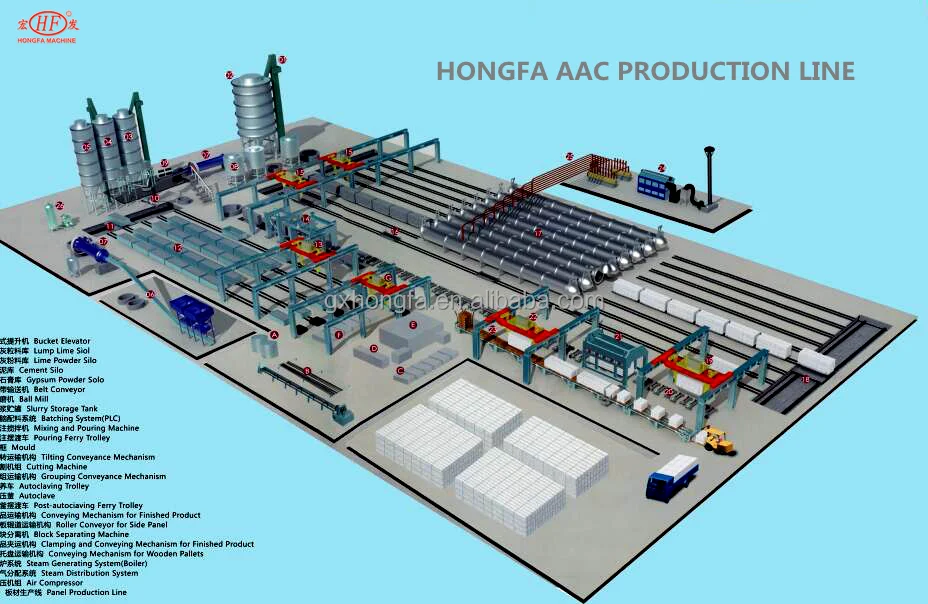

Main process flow of Autoclaved Aerated Concrete AAC Blocks Plant Production Line

Manufacturer Sand Lightweight AAC Block Making Machine AAC PLANT ENGINEERING

Hongfa Group service

Feasibility studies

Analyse the Market for new Plant.

Analyse the right location (include to Market and to Raw material Supply).

Investigate and Analyse the Raw materials.

Investigate and Analyse the existing Energy-supply.

Plant Engineering

Creating an AAC machine package based on required capacity and Product range.

Design and Engineer based on the machinery the Facility including infrastructure and Storage area.

Design and planning of machine layout and placement.

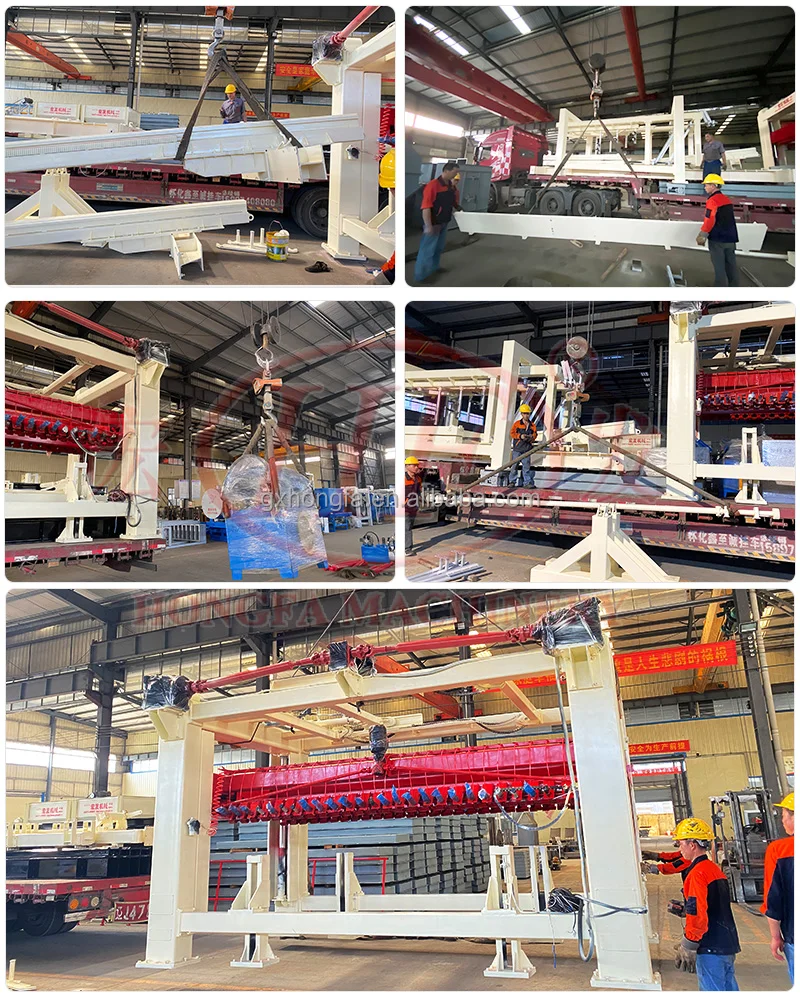

Delivery of machinery and equipment.

Erection and commissioning.

Civil works

Create a construction schedule and timeline.

Provide Superintended for all Civil, mechanical, electrical and construction works.

TECHNICAL DATE

The technology that Hongfa AAC Block AAC Production Line mainly adopts the Germany Yitong process to realize the green body turning in the air, the fixed-step cutting of the green body walking, the hydraulic lifting and conveying, the bottom turning in the air, and the defoaming treatment of the steam drum.

HHongfa is a complete solution supplier and a complete set of equipment production supplier.

Raw material preparation for AAC plant:

A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

The advantages of Hongfa AAC Block Production Line

· 1. It can realize the mixed grinding to prepare the cementitious material and effectively improve the pouring stability; the flow-tube type pouring stirring can shorten the stirring time and greatly improve the uniformity of stirring.

· 2. Raw material processing can realize the hydrothermal ball milling process and improve the stability of fly ash and mortar.

· 3. Staggered batching process. The batching building is divided into two and staggered. It simplifies the layout of equipment and building structure, and meets the requirements of staff space and equipment layout.

· 4. Integrated layout technology, which arranges the batching, pouring, pre-cultivation, cutting, bottom removal, marshalling and other processes in the same workshop. Uses hydraulic lifting and conveying equipment to separate the walking guide from the main body of the workshop and reduce the height of the workshop. Layout, avoiding dead corners in the building, shortening the return path of waste water and waste slurry, reducing the moving space of operators and improving work efficiency.

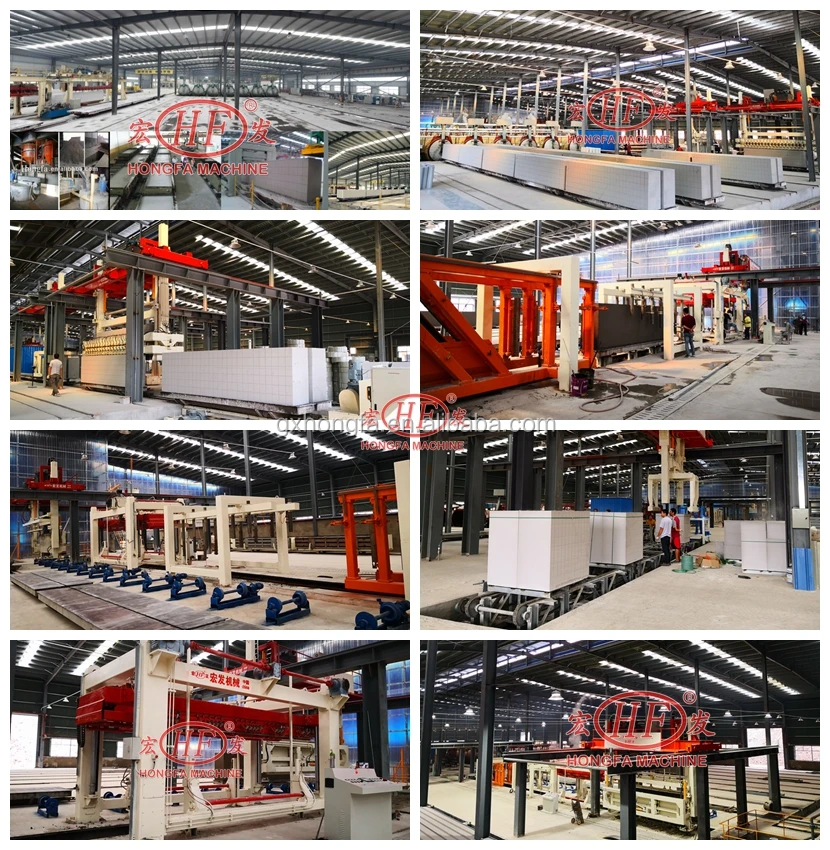

Hongfa AAC BLOCK PRODUCTION LINE SUCCESSFUL PLANTS

Hongfa Group support High precision, professional AAC blocks making machine, AAC block prodcution manufacturing equipment

Hongfa supply Intelligent and efficient autoclaved aerated concrete complete line system solution

Hongfa Committed to providing customers with high-quality services through advanced technological innovation and customized design concepts, strictly controlling product quality, and fulfilling service commitments. In order to ensure the flexibility, reliability and stability of each action of the equipment before leaving the factory, a factory debugging mechanism for single-machine equipment has been established. It is required that each piece of equipment must be fully assembled before leaving the factory after the partial assembly is completed, and electrical and hydraulic debugging must be carried out to ensure the performance of the product when it leaves the factory. At the same time, relevant adjustments are made to the planning scheme and process formula according to the customer's terrain and raw material conditions.

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 40 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!

Hongfa Machinery is your best choice

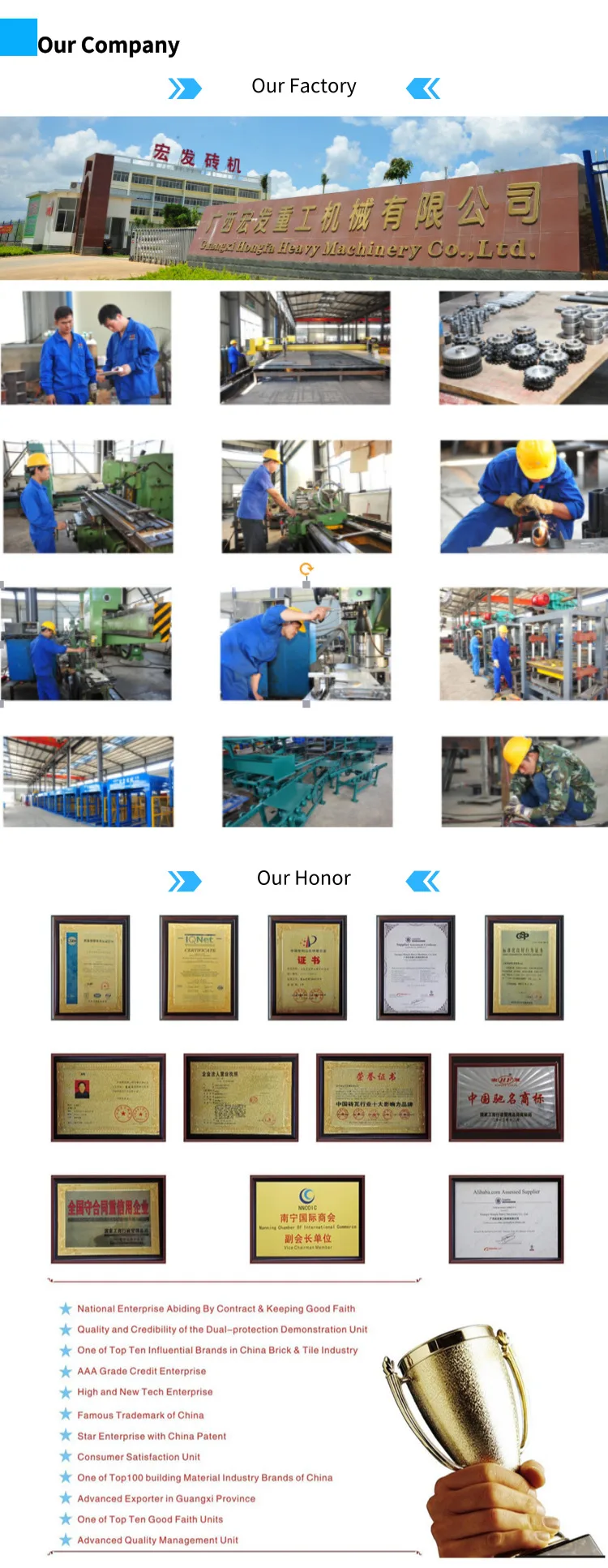

Brand and quality

We are a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine,concrete mixing plant,mixer,concrete block making machine,concrete tile making machine and concrete pipe making machine etc. with more than 30 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick & Tile field in China" and other honors.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, etc., 132 countries and regions, deeply welcomed by clients from all around the world.

Hongfa Machinery Group Main Products :

Main products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic

Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Automatic Block Making:

QT12-15D QT12-15 QT10-15D QT10-15 QT9-15 QT8-15D

QT8-15B QT6-15D QT6-15C QT6-15B QT4-15D QT4-15C

QT4-15B QT4-20C QTJ4-25

Semi-automatic:

QTJ4-35B2 QTJ4-40B2

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

QT3-20 SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~300000M3/Year

FAQ

When you plan to purchase a certain machine, suggesting to take care below points:

1. What is the brand? ( Now a lot companies embezzle our brand, please take note our prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market?(we got good reputation and are the biggest supplier in China)

3. What is the materials they used? Manganese steel or A3 steel? (We use Manganese steel which stronger than A3 steel)

4.What is the guarantee period? ( We guarantee for one year)

5.The price cover to what equipment?( pls refer to our quotation list)

Please not hesitate to contact us if you are interested in any kinds of products.

Contact Information:

Foreign Trade Dept. :Jiffy

Tel:0086-18260911699 (whatsApp)

Fax:0086-771-6036901

Guangxi Hongfa Heavy Machinery Co., Ltd.

Wesite: www.gxhongfa.cn

Pesanan tiba sebelum jadwal, atau dapatkan kompensasi 10% dari harga pesanan jika pengiriman telat.

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan