[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Scrape dryer

Description :

Scrape dryer is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum.Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film,to evaporate the moisture in materials film so as to dry materials.Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the blade,and are conveyed,collected and packed.

Technical parameters:

| Item Model | Cylider Size | Effective Heating Area (m²) |

Drying cacity kg.water/m².h |

Steam Consumption kg/h |

Power (kw) |

Dimension (mm) |

Weight (kg) |

| GRT-600 | 600*800 | 1.12 | 40-70 | 100-175 | 2.2 | 1700*800*1500 | 850 |

| GRT-700 | 700*1000 | 1.65 | 60-90 | 150-225 | 3 | 2100*1000*1800 | 1210 |

| GRT-800 | 800*1200 | 2.26 | 90-130 | 225-325 | 4 | 2500*1100*1980 | 1700 |

| GRT-1000 | 1000*1400 | 3.3 | 130-190 | 325-475 | 5.5 | 2700*1300*2250 | 2100 |

| GRT-1200 | 1200*1500 | 4.24 | 160-250 | 400-625 | 7.5 | 2800*1500*2450 | 2650 |

| GRT-1400 | 1400*1600 | 5.28 | 210-310 | 525-775 | 11 | 3150*1700*2800 | 3200 |

| GRT-1600 | 1600*1800 | 6.79 | 270-400 | 675-1000 | 11 | 3350*1900*3150 | 4350 |

| GRT-1800 | 1800*2000 | 8.48 | 330-500 | 800-1200 | 15 | 3600*2050*3500 | 5100 |

| GRT-1800A | 1800*2500 | 10.6 | 420-630 | 1050-1575 | 18.5 | 4100*2050*3500 | 6150 |

Applications :

It is suitable for drying liquid raw material or sticky material in chemical industry,dyestuff industry and so on.

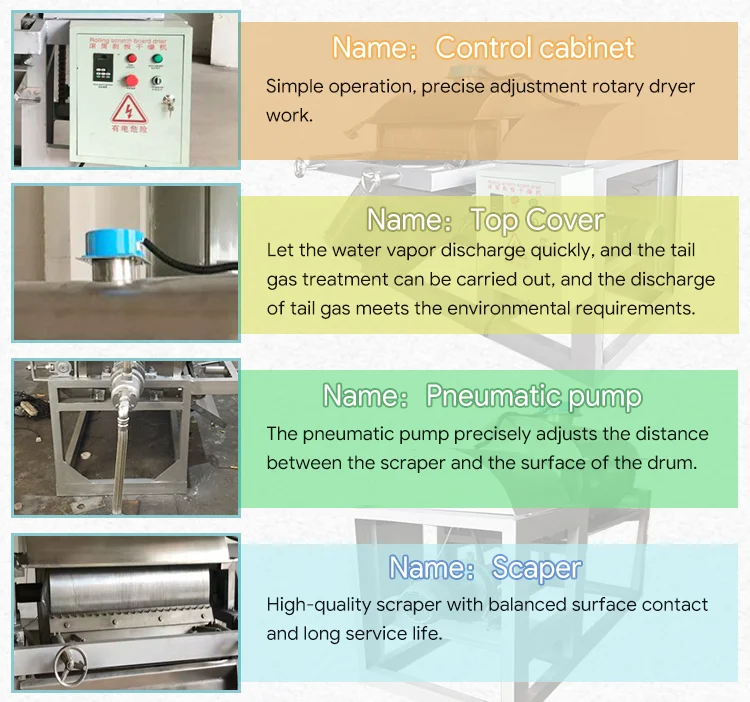

Features of Scraper Dryer

1.High thermal efficiency. Because the heat transfer mechanism of the drum dryer is heat conduction, the heat transfer direction is consistent throughout the rest of the operation cycle. Except for the cover heat dissipation and heat radiation loss, the heat is all used for the evaporation of the wet film of the film, and the thermal efficiency can reach 80%~90%.

2.The operation is flexible and wide in applicability. Many drying factors can be adjusted for the drum dryer. For example, the concentration of the feed, the thickness of the coating film, the temperature of the heating medium, the rotation speed of the drum, etc., can change the drying efficiency of the drum dryer, and many factors are not involved. This brings great convenience to the drum drying operation, so that it can adapt to the drying of various materials and different production requirements.

3.Drying time is short. The drying cycle of the material is generally only 10-300 seconds, which is more suitable for heat sensitive materials. If the drum dryer is placed in a vacuum, it can be operated under reduced pressure.

4.The drying rate is large. Since the coating film is thin on the wall of the cylinder, generally 0.3-1.5mm, and the heat transfer and mass transfer directions are the same, and the surface of the film can maintain the evaporation strength of 100-150kg H2O/m2.h.

1. Provide comprehensive technical and consulting services;

1.Are you manufacturer or trader? Where are your factory located?

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan