[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Suku cadang gratis

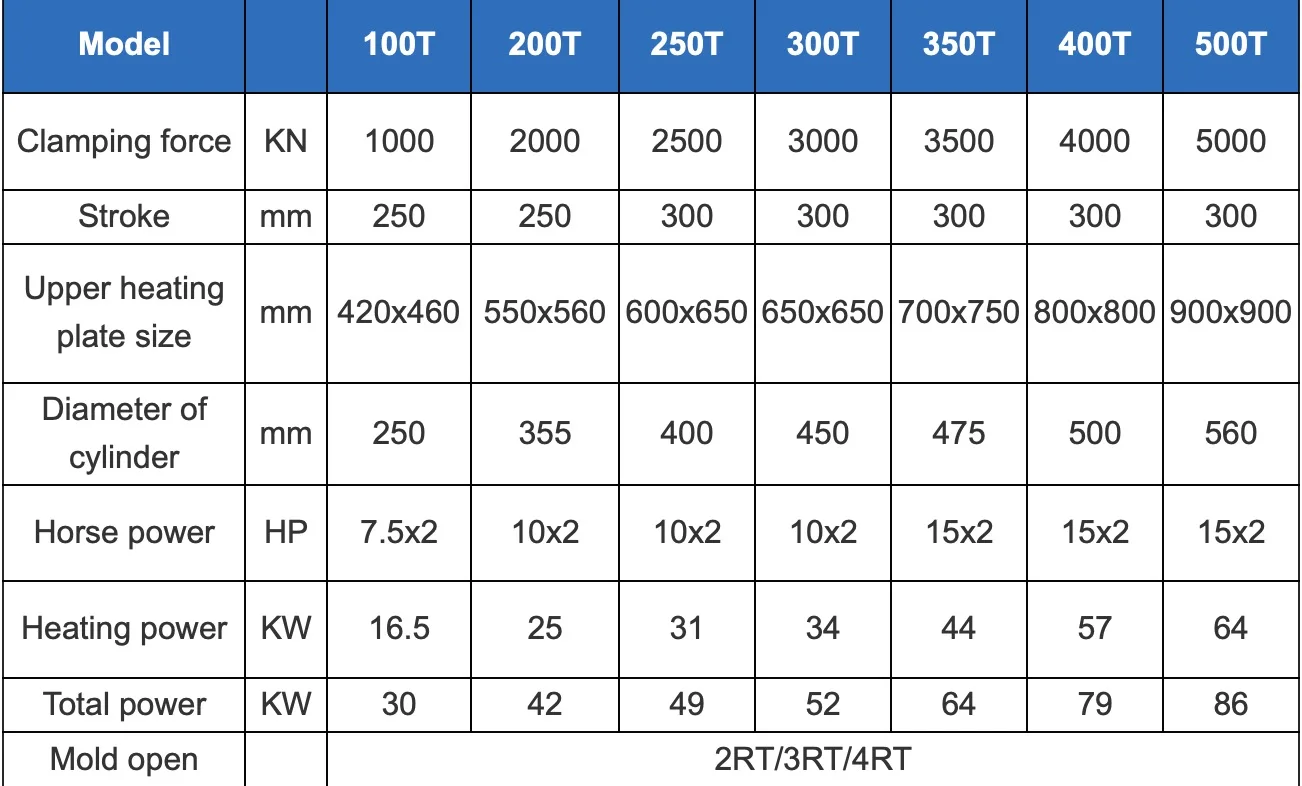

Suku cadang gratissilicone rubber oil seal making machine/ rubber vacuum vulcanizing press molding machine

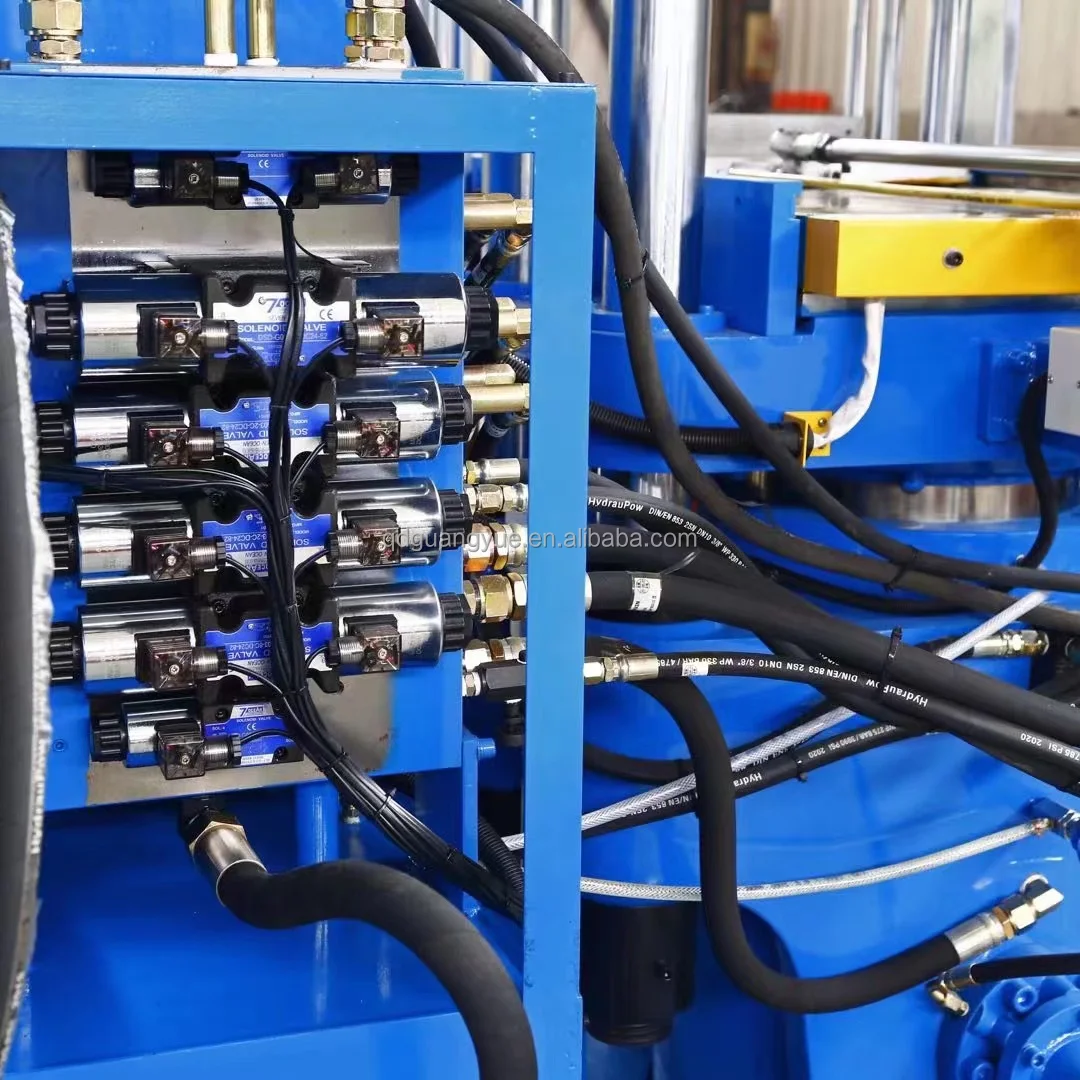

1. It adopts double power, double oil pump, double motor, double cooler, and double shaft work completely independently.

2. The oil circuit system is specially designed, no vibration, good stability, entering and exiting the mold, rising and falling faster than the counterparts.

3. The vacuum degree is high, and the average pumping method is adopted to stabilize the product and improve the quality and production capacity.

4. The vacuum gas storage tank is base type, and the gas storage space is large.

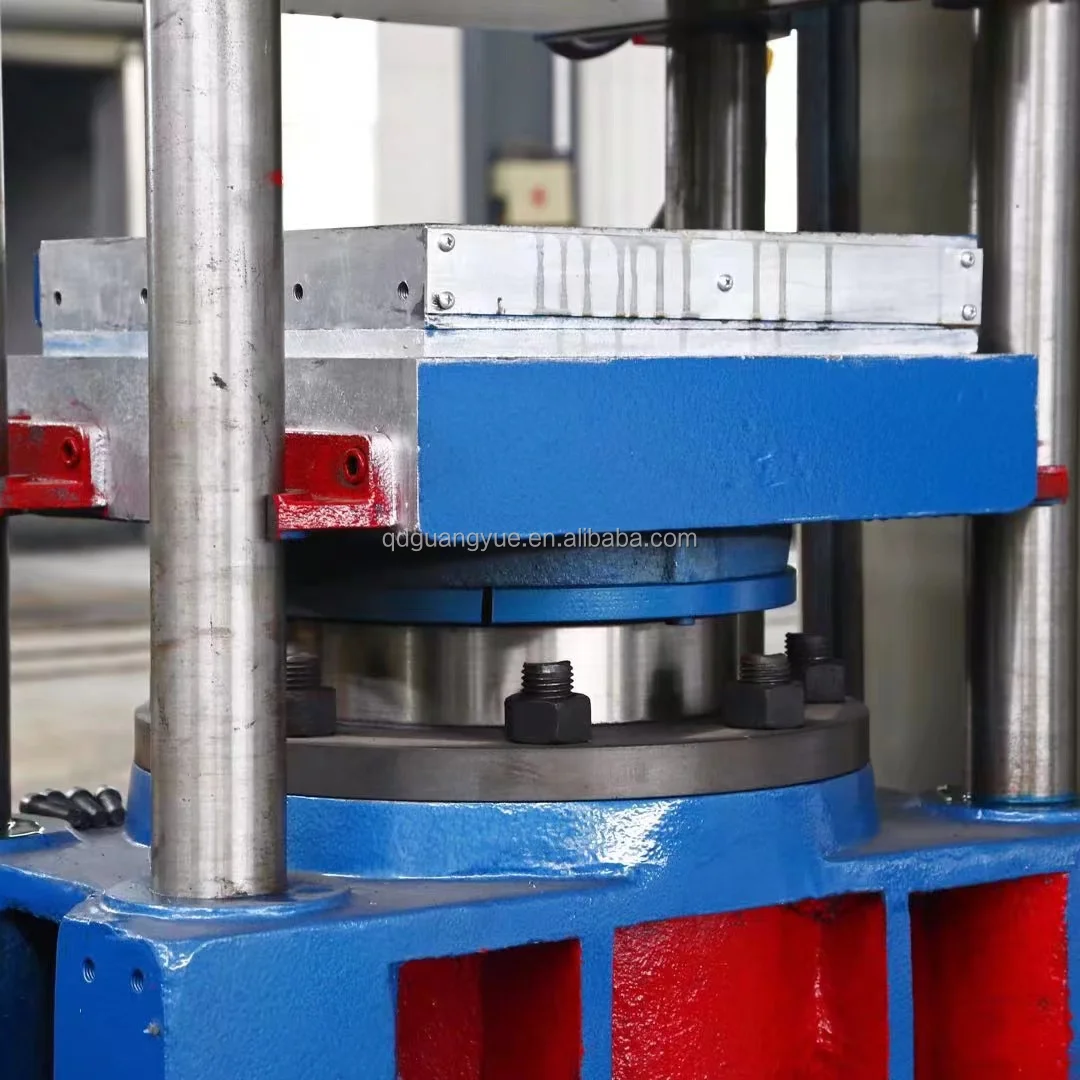

5. The new type of mold lift mechanical design, durable and long life, quiet, fast and stable in and out of the mold.

6. Suitable for shock absorbers, medical bottle stoppers, auto parts, gaskets, conductive buttons, electronic products and other precision silicone rubber products.

Configurations:

* Made of nodular cast iron, the oil cylinder of machine is improved in compressive strength and wear resistance.

* Seal ring made of oil-proof rubber is placed in oil cylinder to have sealing effect in working process of this machine.

* Adopting tubular electric-heating component to heat up, the machine can reduce air pollution to keep workshop clean without boiler.

* The machine is beautiful in shape, rational in structure, convenient in control, safe and credible as well.

Our strength

1 manufacturer direct sale, can ensure delivery time and quality.

2 plunger diameter difference is very small,which ensure pressure.

3 our vulcanizing press is equiped with automatic controling temperature and pressure, automatic alarm, automatic loading ,emergency stop ,digital readout and son on.

4 low noise, no oil leakage, no pressure off.

5 small temperature difference of hot plate,Plate temperature tolerance: ±1°C, which follows the national standard.

6 the parallelism differnce does not exceed ±0.01-0.02mm

7 heating method according to your request : electricity , steam heating , conduction oil heating .

8 we can make machine according to the your request.

9 we can give a discount according to your quantity

Rubber oil seal making vacuum heating press machine , Hydraulic Molding Vulcanizing Press Machine configuration list

|

Main Configuration |

|

|

PLC |

Mitsubishi |

|

Touch screen |

Siemens |

|

Electric elements |

Schneider |

|

Electromagnetic valve |

Yuken |

|

Heating control |

Gold |

|

Temperature control |

Omron |

|

Pressure gauge |

Dmass |

Main part of the vulcanizer

factory direct sales, good quality and favorable price :

100% factory manufacture

Q:Are you factory or trading company?

A:We are a manufacturer with over than 15years of experience in Rubber Machine.

which include: plate vulcanizing press, open rubber mixing mill, banbury intensive kneader, extruder, rubber machinery, textile machinery,shot blast cleaning machine, foundry machinery, woodworking machinery, wheel barrow and tire etc

Factory Add: Huang Shan Economic Zone, Jiaonan, Qingdao, Shandong, China (Mainland)

Welcome your visiting and we can arrange our driver to pick up you.

Q:What advantages do you have?

We have15 years trust of our customers. Guarantee Quality and timely Delivery !

Skilled QC staff and do the best quality control,Fast shipment as per customers requirement.

Q: What are your delivery times?

The delivery time is 20-45 days after order be confirmed. For the exact date,please check with our sales team.

Q:What kind of surface treatment do you provide for your goods?

Galvanized ,chrome coating or powder coating are available. We can also make it according to our customer’s requirement.

Q:I’m not sure about your product, can you send me sample for reference?

Our standard product samples are free of charge except for the freight fee.

For customized products, sample fee as well as the freight fee are charged.

1.pre-sale services

Act as a good adviser and assistant of client enable them to get rich and generous returns on their investments.

1)select equipment model

2)design and manufacture products according to clients' special request

3)train technical personnel for clents.

2.services during the sale

1)Recheck and accept products ahead of delivery

2)Help clients to draft solving plans

3.after-sale services

1)provide considerate services to minimize client's worries.

2)Help client to solve the assembly question

3)take responsibility if any technical problem

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.

Akses ke penggantian komponen gratis dan jaminan perbaikan